AP-6012CNC 3D 5 axis fiber laser tube cutting machine

Fiber cutting tube wall thickness

Max 20mm quality 16mm or less

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | AP-6012CNC 3000W |

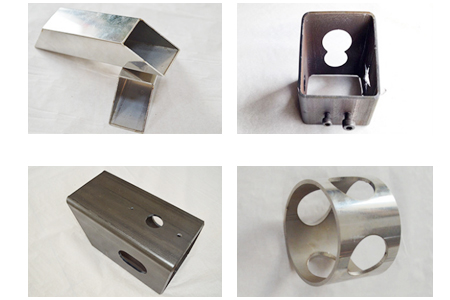

| Cuttable Material Type | Round tube, Square tube,Rectangular tube,Channel steel,Angle steel H shape steel |

| Fiber cutting tube wall thickness | Max 20mm quality 16mm or less |

| Cut material length | 12000mm |

| Diagonal Section | 30-600mm |

| Overall body length | 14000mm |

| Overall length of the machine | 16000mm |

| Equipment weight | 5500KG |

| Positioning accuracy | 0.05-0.1mm |

| Cutting accuracy | 0.2-0.6mm |

| Max cutting speed | 30m/min |

| Laser source electricity consumption | 3KW |

| Lathe electricity consumption | 8KW |

| Water chiller electricity consumption | 3KW |

Resources & Downloads:

AP-6012CNC 3D 5 axis fiber laser tube cutting machine Product Introduction :

Product Details

This machine is used for cutting metal round and square tubes, channel steel, angle steel, H shape steel etc. It adopts a 19-inch high-resolution LCD color display, which can display cutting graphics and cutting running tracks. Cutting programs can be edited manually.

It adopts five-axis perfect cutting, which can cut round pipe, square pipe, channel steel and angle steel H shape steel .

In addition, it supports functions such as pause, forward, backward, and speed regulation during processing.

It can store 200G files and can be used at will. It is driven by high-efficiency servo motor, with fast speed, high efficiency, high precision and stable operation. High-flexible shielded wire is used to truly resist high-frequency interference.

It is suitable for various fiber optic models. The movable beam can save tailings.

The front chuck is equipped with two sets of intelligent follow-up splicing devices to facilitate the For long material processing requirements, there is a set of intelligent follow-up material support systems in between, so as to avoid Buyer’s long material sagging and affecting the cutting accuracy.

| No. | Name | Model |

| 1 | Electrical control cabinet | ZLQ-XGEC |

| 2 | Laser | 3000W |

| 3 | CNC pipe cutting system | EOE-HZH |

| 4 | Bed composition | Double bottom beam design 14m |

| 5 | Servo drives and motors | 1.0KW |

| 6 | Front and rear chuck motors | 1.0KW |

| 7 | Rack thickness | 6mm base/8mm X beam |

| 8 | X Z axis motor | 400W |

| 9 | Y-axis motor | 750W |

| 10 | Reducer | 40:01:00 |

| 11 | Spin chuck | Diagonal 30-600mm |

| 12 | Front chuck | Manual double-action design self-centering |

| 13 | Rear chuck | Pneumatic single-acting design self-centering |

| 14 | Laser head | 1 set |

| 15 | Machine head gantry | 1set |

| 16 | Train track | 14 sets (2m/set) |

| 17 | Heavy-Duty Front Catcher Unit | 2 sets,with buffing |

| 18 | Heavy-duty intermediate support system | 1 set,with buffing |

| 19 | Cable | Heat resistance grade PE-7, plus shield |

| 20 | Computer | Industrial control high and low temperature computer |

| 21 | Distribution box | Add two more cooling treatments |

| 22 | Move the wheel | Increased anti-wear and anti-warping design |

| 23 | Chiller | 3000w |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life