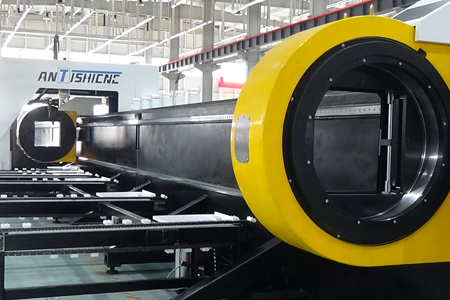

AP-12055 Pipe Fiber laser cutting machine (Side-mounted)

Max. cutting dia. : 550mm

Min. cutting dia. : 20mm

Max. cutting length : 12000mm

Min. cutting length : 150mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | AP-12055 |

| Working area | 12000mm*Φ550mm |

| Laser type | Fiber laser generator |

| Laser power | 12000w Raycus |

| Graphic format supported | CAD. DXF (etc) |

| Voltage | 380V 60Hz |

| Working environment | Temp:0-40℃,humidity:≤80% No condensation |

| Position accuracy | ±0.03mm/1000mm |

| Reposition accuracy | ±0.02mm/1000mm |

| Transmission system | Gantry structure |

| Lubrication system | Full-automatic |

| Max speed | 30 rotates /Min |

| Max accelerated speed | 1.0G |

| Max. cutting diameter | 550mm |

| Min Cutting diameter | 20mm |

| Max. cutting length | 12000mm |

| Min. cutting length | 150mm |

| Machine body | Gantry milling, De-stressing, De-firing |

Resources & Downloads:

AP-12055 Pipe Fiber laser cutting machine (Side-mounted) Product Introduction :

1. Cutting process

Laser cutting is the best cutting method in all kinds of cutting technology mastered by people nowadays. Compared with traditional cutting, the advantages of laser cutting lie in:

Contactless cutting, small thermal deformation;

Linear cutting has high precision and fast speed;

Showing a low-carbon, environmentally friendly way;

Automatically cutting is easy to achieve, improving machining efficiency;

Buying something costs 50% less than machining.

Fiber laser wavelength is 1.07-1.08μm, is 1/10 of the wavelength of CO2 laser, is more conducive to be absorbed by metal materials, cutting carbon steel, stainless steel and aluminum alloy speed is not only faster, but also can cut aluminum coated zinc plate, and pure aluminum, brass, copper and other high reflection non-ferrous metals; Optical fiber transmission, full flight optical path, especially suitable for cutting all kinds of complex parts; Powerful NUMERICAL control system and nesting software to solve many technological problems, further improve the cutting accuracy, perforation speed, simple and convenient operation. The laser is directly transmitted to the cutting head of the machine by the laser through the optical fiber. The mechanical structure is simple, the optical path is constant, the basic maintenance is free, and the cutting performance is stable. The fiber laser uses the rare element Ytterbium as the luminescent material, without high purity helium, nitrogen, carbon dioxide and their consumption. Electricity to light conversion rate up to 30%, more low-carbon, economic.

2. Advantages of fiber laser cutting

Cutting head, with the use of capacitive induction control, so that the nozzle in the cutting process is always consistent with the workpiece surface distance, so it can not only complete the plane cutting, but also can complete all kinds of uneven surface cutting;

Cutting quality is good: no contact cutting, cutting edge affected by heat is very small, basically no workpiece thermal deformation, can avoid the collapse of the edge formed when the material punching shear, slit generally do not need secondary processing;

Save mold investment: can complete a variety of complex structure processing, only need to draw any image on the computer can be laser processing, no mold, no mold consumption, no need to repair the mold, save the time to replace the mold, so as to save the processing costs, reduce the cost of production, especially suitable for the processing of large products;

Material saving: the use of computer programming, can be different shapes of products for cutting, maximize the utilization of materials.

Machine Configuration

| NO. | Name | Model | QTY | Remarks |

| 1 | Fiber laser cutting machine | AP-12055 | 1 SET | Standard |

| 2 | Laser source | 12000W | 1 SET | Raycus |

| 3 | Auto focusing high precision special cutting head | Laser head | 1 SET | BLT6 series |

| 4 | Special chiller for fiber laser | Original | 1 SET | S&A |

| 5 | Control system | system | 1 SET | FSCUT 5000 |

| 6 | Z axis drive system | High speed servo motor&driver | 1 SET | FUJI |

| 7 | X axis drive system | High speed servo motor&driver | 1 SET | FUJI |

| 8 | Y axis drive system | High speed servo motor&driver | 1 SETS | FUJI |

| 9 | W axis drive system | High speed servo motor&driver | 3 SETS | FUJI |

| 11 | Reducer | Original | 5 SET | MOTOREDUCER |

| 12 | Electric components | Original | 1 SET | SCHNEIDER |

| 13 | Rail | Line rail | 1 SET | Taiwan HIWIN |

| 14 | Rack | Grinding rack | 1 SET | Taiwan YYC |

| 15 | Proportional valves | Original | 1 SET | SMC |

| 16 | Beam and gantry | Aviation aluminum beam | 1 SET | Standard |

| 17 | Chucks | Pneumatic | 3 SETS | Length: 12000mm Max diameter: 550mm |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life