Sawing machine

Milling Machine

Grinding Machine

Lathe Machine

Drilling machine

EDM/WEDM Machine

Laser Cutting Machine

Slotting Shaping Machine

Metal Forming Equipment

Tubes and Profile Processing

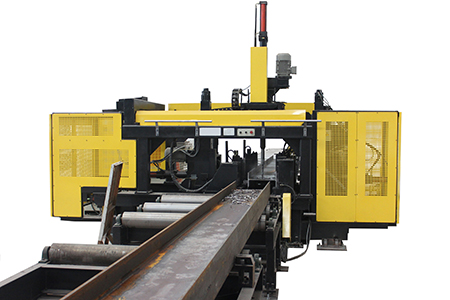

SWD Series PLC Control 3D Beams Drilling Machine

Max.Thickness : 80mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | SWD1000 | SWD1250 | SWD1400 | |||

| Work-piece size | H-beams Max. (web height×flange width) | Max. | 1000×500 | 1250×600 | 1400×600 | |

| Min. | 150×75 | |||||

| Length (mm) | ≥2000 | |||||

| Max.Thickness (mm) | 80 | |||||

| Drill dia. (mm) | Vertical drilling | Φ12~Φ40 | ||||

| Horizontal drilling | Φ12~Φ40 | |||||

| Spindle units | Qty. of spindle | One spindle on each of three sides (top,left,right) Total: 3 spindles | ||||

| Rotation speed (rpm) | 120~560 | |||||

| Spindle motor power (kW) | 3×4 kW | |||||

| Max. feeding stroke (mm) | Left,Right:140 Vertical: 325 | |||||

| Feeding speed (mm/min) | 20~300 | |||||

| Movement of left/right spindle (mm) | In the direction of work-piece length::520 | |||||

| Above vertical base-level:30~470 | Above vertical base-level:30~570 | Above vertical base-level:30~570 | ||||

| Movement of top spindle (mm) | In the direction of work-piece length:520 | |||||

| Beyond horizontal base-level:45~910 | Beyond horizontal base-level:45~1160 | Beyond horizontal base-level:45~1310 | ||||

| Marking

(Optional) |

Qty. of characters | 36 characters | ||||

| Character size (mm) | Φ10 | |||||

| Overall dimensions(LxWxH) (m) | 4.55×3.05×3.52 | 4.8×3.05×3.52 | 5.2×3.05×3.52 | |||

| Machine weight (Kg) | About 7000 | About 8000 | About 9000 | |||

Applicable Industry:

This machine is special equipment used for the drilling processing of H beams, channel steel of steel structure, bridge, three dimensional garage and petrol platform industries.

Product Feature:

1.Equipped with three drilling units, three drilling units can drill holes simultaneously and adopt self-controlled stroke drilling head.

2.No need to set Thickness of work piece and length of drill bits, it will do fact-feeding or feeding automatically by sensor signal, and with high efficiency.

3.Frame made of sturdy elector-welded and normalized Plates and Square Beams. The structure with roller guides on which the sliders supporting the three spindles guarantees the total moving stability, and ensures the working precision;

4.This machine can read AUTO-CAD drawings and lofting software files automatically, such as DXF, NC1.

5.Equipped with automatic lubrication system and air conditioner for electric cabinet.

6.Equipped with automatic feeding systems, which will clamp and feed material into machine automatically.

7.PLC systems, programming based on WINDOWS, fast and convenient programming, and visual previewing.

8.Drilling units equip with famous brand spindle motor.

9.The key mechanical, hydraulic and electric parts are all famous brands.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.