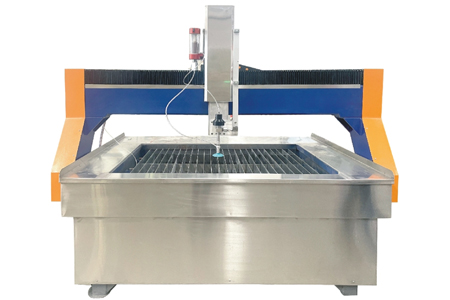

CNC waterjet cutting machine (Integral gantry structure)

X, Y, Z axis travel :

3000*2000*150 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Paramelers | unit | AT-L-1010 | AT-L-2015 | AT-L-3020 |

| Efficient Cutting area | mm | 1000*1000 | 2000*1500 | 3000*2000 |

| Axis travel | X:mm | 1000 | 2000 | 3000 |

| Y:mm | 1000 | 1500 | 2000 | |

| Z:mm | 150 | 150 | 150 | |

| Cutting accuracy | mm | ±0.1 | ±0.1 | ±0.1 |

| Positioning accuracy | mm | ±0.025 | ±0.025 | ±0.025 |

| X,Y dry-run speed | M/min | 0-15 (if 0-30m speed is required, it can be customized) | ||

| Cutting speed | M/min | Depending on the specific material and thickness | ||

Resources & Downloads:

CNC waterjet cutting machine (Integral gantry structure) Product Introduction :

Main features:

1. Y-direction double supports, two-way ball screws, and linear rolling guide transmission ensure the operation, speed and accuracy of the cutting head.

2. Unique automatic lubrication system, using high-quality drag chain and special moving cable, is durable.

3. Both the X and Y axes use high-precision ball screws and linear guides.

4. Special tooling can be customized according to the cutting requirements of different materials.

Application industries:

1. Metal materials: Water cutting is suitable for various metal materials, such as steel, copper, aluminum, cast iron, titanium, zirconium, chromium, etc.

2. Non-metallic materials: Water cutting is also suitable for cutting various non-metallic materials, such as marble, glass, ceramics, rubber, plastic, paper, etc.

3. Composite materials: Water jet cutting can also cut various composite materials, such as fiberglass, polyurethane, core sheets, laminated boards, etc.

4. Architectural decoration: Water cutting is suitable for cutting various building materials, such as ceramic tiles, glass, marble, etc. In architectural decoration, water cutting can create a variety of beautiful decorative patterns.

5. Industrial manufacturing: Water cutting is widely used in the field of industrial manufacturing. Through water cutting technology, various industrial materials such as steel, copper, aluminum, ceramics, etc. can be cut quickly and accurately.

6. Art processing: The precision of water cutting is very high, and it can cut a variety of exquisite works of art. In the fields of sculpture, ceramics, glass and other fields, water cutting is a very important processing method.

7. Mold manufacturing: Water cutting can be used to manufacture various molds. Through water cutting, various molds can be manufactured quickly and accurately without affecting the accuracy and quality of the molds.

8. Other fields: Water cutting can also be used to cut food, paper and other materials, and is also widely used in medical device manufacturing, automobile manufacturing and other fields.

In short, water cutting has the advantages of high efficiency, precision, and no pollution. It is suitable for cutting a variety of materials and is widely used in various industries

| ANTISHICNC Waterjet Cutting Machine Main Parts Introduction(Selected) | |||

| Main Motor (SIEMENS BEIDE) |

OIL Pump (Heng Yuan) |

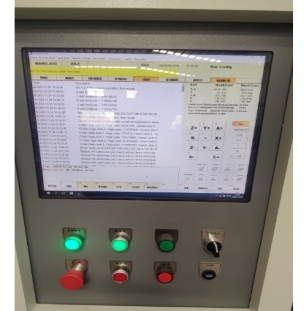

CNC SYSTEM (WEIHONG) |

Server Driver (WISE/PANASONIC) |

|

|

|

|

| Pressure Booster Unit (ANTISHICNC) |

PLC SYSTEM (SIEMENS) |

Industrial PC (NC-65C) |

Heavy duty Machine body (ANTISHICNC) |

|

|

|

|

| AC Fix-Axis Cutting head | Industrial Chiller(Customer Define) | Transmission Unit (ABBA/TBI/HIWIN) |

Standard export wooden (ANTISHICNC) |

|

|

|

|

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life