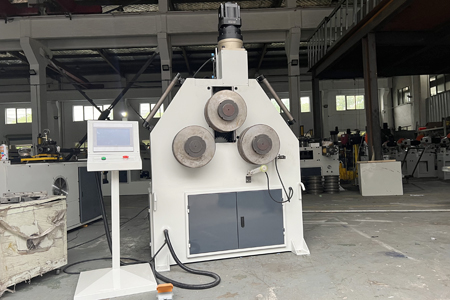

Fully Automatic Servo Rounding Machine GY100CNC-1A-3

Max. pipe bending : Φ100 x 8mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Main specifications | GY100CNC-1A-3 | Remark |

| Max. pipe bending capacity | Φ100mm x 8mmCarbon steel pipe | Specifications can be according to customer requirements |

| Mini. elbow radius | (R﹥300 according to pipe material) | |

| Bending speed | adjustable | |

| The mold diameter | 300mm | |

| Shaft diameter | 100mm | |

| Compression servo | 5KW | |

| Machine size/weight | According to the machine |

Meet the following processing requirements:

For square/rectangular:

16mm

20mm

30mm

40mm

50mm

60mm

70mm

80mm

Round:

21.30mm

26.70mm

33.40mm

42.50mm

48.30mm

60.30mm

72.20mm

88.90mm

Resources & Downloads:

Fully Automatic Servo Rounding Machine GY100CNC-1A-3 Product Introduction :

Features

This equipment is a custom-made special equipment. According to the characteristics of the customer’s product, the main machine adopts servo rounding, PLC control system, and full gear transmission mechanism. The man-machine dialogue is simple and the efficiency is high. Arcs of different radii can be realized on the same material;

1. Fully mechanical transmission with compact structure and high reliability

2. Adopt high-performance imported hydraulic valve components.

3. Driven by seven rollers, it is not easy to slip, and thin-walled materials can also be bent.

4. The rollers on both sides are distributed asymmetrically to reduce the straight section.

5. Foot switch accelerates emergency stop, easy to operate

6. The drive of the machine is balanced, only need to adjust the compression, can obtain different curvature of the circle, arc or spiral.

7. Changing the groove shape of the mold can process various metal profiles, such as angle steel, flat steel, round pipe and other special-shaped cross-section profiles.

8. Bending large-radius profiles avoids the disadvantages of making extra-large pipe bending molds, and is a necessary supplement that series single-head and double-head pipe benders cannot achieve.

9. This machine is suitable for medium and large batch production, with high speed and high efficiency.

Main Parts for the machine

| Specifications | Supplier |

| Main electrical appliances | Taiwan |

| Starting from the spindle | China |

| The nose | China |

| Induction switch | China |

| Switching power supply | Taiwan Ming weft |

| Bearing | China |

| Ball screw | Taiwan |

| Touch screen | WEILUN |

| Servo motor | Mitsubishi , Japan |

| Servo drive | Mitsubishi , Japan |

| Transformer | China |

| PLC | Mitsubishi , Japan |

| Reducer | China |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life