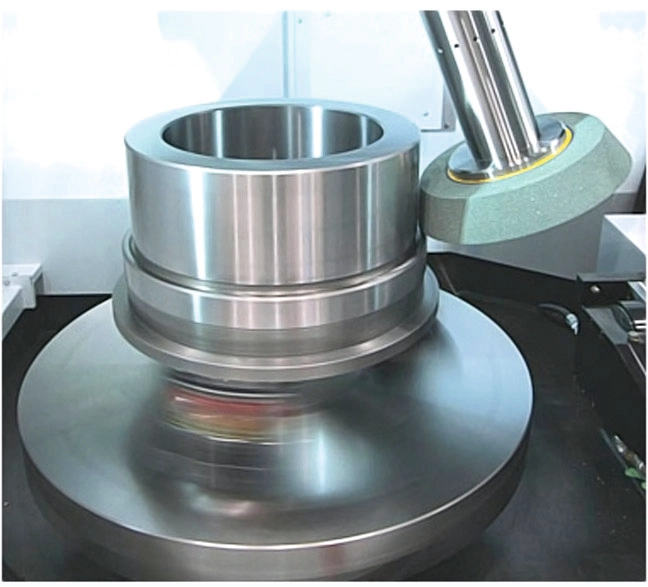

MGK28 Series CNC Vertical Multi-process Verical Grinding Grinder Machine

Max grinding diameter : 2200mm

Max workpiece height : 550mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model

Item |

unit | MGK2860 | MGK2880 | MGK28100 | MGK28100H | MGK28125 | MGK28160 | MGK28200 |

| Capacity of processing | ||||||||

| Maximum workpiece grinding diameter | mm | 750 | 850 | 1100 | 1100 | 1350 | 1800 | 2200 |

| Maximum workpiece height | mm | 400 | 400 | 500 | 1000 | 500 | 550 | 550 |

| Minimum grinding inner hole | mm | 60 | 60 | 100 | 250 | 100 | 350 | 350 |

| Maximum bearing capacity of workbench | kg | 600 | 800 | 2000 | 2000 | 2500 | 3000 | 5000 |

| Worktable | ||||||||

| Diameter of working table | mm | 600 | 800 | 1000 | 1000 | 1250 | 1600 | 2000 |

| Speed of work table | rpm | 200 | 200 | 60 | 60 | 60 | 50 | 40 |

| Precision of rotating | mm | 0.0015 | 0.0015 | 0.002 | 0.002 | 0.002 | 0.003 | 0.003 |

| Spindle | ||||||||

| Maximum spindle speed of vertical grinding wheel | rpm | 10000 | 10000 | 7000 | 6000 | 7000 | 3000 | 3000 |

| Vertical grinding wheel spindle power | kw | 11 | 11 | 15 | 15 | 15 | 18.5 | 22 |

| Maximum spindle speed of horizontal grinding wheel | rpm | – | – | 2500 | – | 2500 | 2000 | 2000 |

| Horizontal grinding wheel spindle power | kw | 11 | 11 | 15 | 15 | |||

Resources & Downloads:

MGK28 Series CNC Vertical Multi-process Verical Grinding Grinder Machine Product Introduction :

Standard Accessories

Youtube Channel : Antishicnc Machine

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life