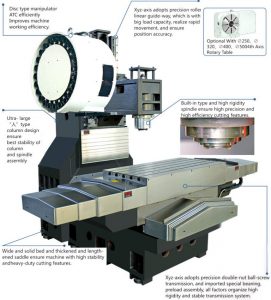

VMC850S Vertical Machining Center

Table Size(L*W) : 900x500mm

Max Loading Weight : 500kg

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Parameters / Model | Unit | VMC850S |

| Table Size(length*width) | mm | 900×500 |

| Max Loading Weight | kg | 500 |

| Number-width x distance | mm | 5-18×90 |

| XYIZ Travel | mm | 800/500/500 |

| Max .Distance From spindle nose to Table Surface | mm | 120-620 |

| Spindle center to Z axis guide surface | mm | 550 |

| Spindle motor power | kW | 7.5/11 |

| Max. Spindle Speed | rpm | 10000 |

| Spindle Taper | BT40 | |

| 3 axis rapid speed | m/min | 48/48/48 |

| Max cutting speed | m/min | 10 |

| Pull stud | MAS403 BT40-45° | |

| ATC capacity | BT40-24T | |

| Max. Diameter of to’length | mm | Φ85×350 |

| Positioning Accuracy | mm | ±0.004 |

| Repeatability Accuracy | mm | ±0.003 |

| CNC system | FANUC/SIEMENS/MITSUBISHI | |

| Machine Size (L”W*H) | mm | 2100x2600x2650 |

| Machine Weight | Kg | 5000 |

Resources & Downloads:

VMC850S Vertical Machining Center Product Introduction :

Product Features:

The machine tool adopts a new generation of vertical machining center with high precision, high speed and high rigidity developed by 3D computer-aided design and finite element analysis. The guide rail adopts three-line rail (or two-line one-hard) guide rails, and the maximum rapid speed can reach 48m / min, spindle speed 6000 to 15000 rpm optional positioning accuracy <4μm, repeated positioning <3μm; suitable for various mechanical processing fields such as mold, military industry, hardware, auto parts and so on.

Product Description :

VMC series vertical machining center inherits the advantages of strong rigidity, symmetrical struc-ture and strong stability of the foundation frame of the traditional vertical CNC milling machine,introduces the international advanced dynamic rigidity design concept, and optimizes the design of the moving parts.

| Number | Standard configuration | Number | Special configuration |

| 1 | The back row chip full cover sheet metal without the chip | 1 | Front row chip full cover sheet metal belt chip remover |

| 2 | Drawer type water tank and chip box | 2 | Central outlet function of spindle |

| 3 | Backward impact chip washing device | 3 | 3 axis linear scale |

| 4 | Full-function operation panel and handwheel | 4 | Function of the fourth axis |

| 5 | ATC | 5 | Spindle oil cooling function |

| 6 | Belt drive spindle | 6 | Straight connection drive spindle |

| 7 | Sprinkler cooling system at the spindle side | 7 | Oil-water separation device |

| 8 | Air cooling system at spindle side | 8 | Workpiece and tool measuring device |

| 9 | Heat exchange device of electric cabinet | 9 | Door open switch |

| 10 | Work area cleaning water gun, air gun | 10 | High speed and high precision functions |

| 11 | Working light and alarm light | 11 | Column elevation (bridge type or height block) |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life