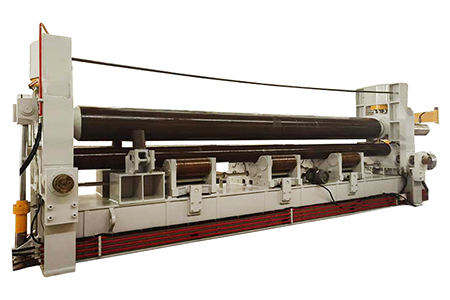

W11-30X2000 Mechanic Three-roller Plate Rolling Machine

Maximum working length:2000mm

Maximum plate thickness:30mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | W11-30×2000 | |

| Type | Mechanically symmetric | |

| Maximum working length | mm | 2000 |

| Length of working length | mm | 2050 |

| Maximum plate thickness | mm | 30 |

| Plate yield strength | Mpa | 245 |

| Upper roll diameter | mm | ¢360 |

| Lower rolls diameter | mm | ¢290 |

| Distance between lower rolls | mm | 550 |

| Minimum reel diameter(full load) | mm | T30×B2000×Φmin1200mm |

| Rotation speed | m/min | About 4 |

| Main motor power | kw | 30 |

| Auxiliary motor power | kw | 11 |

Resources & Downloads:

W11-30X2000 Mechanic Three-roller Plate Rolling Machine Product Introduction :

Performance and features:

The structure of this machine tool is three-roller symmetrical. The upper roller moves vertically in the central symmetrical position of the two lower rollers through mechanical transmission; the two lower rollers rotate, and the output gear of the reducer engages with the gear of the lower roller to provide torque for the rolled plate. This machine has a compact structure and is easy to operate and maintain.

Uses and scope of application

This machine is a three-roller symmetrical, upward-adjustable plate rolling equipment, mainly used to bend metal plates during cold working, and bend them into cylinders of various diameters. It is widely used in mechanical industries such as boilers, chemicals, mining, construction, and shipbuilding.

Main structure and working principle

1.This machine is an upward adjustment symmetrical plate bending machine, which completes the rolling of cylindrical workpieces by pressing down the upper roller and rolling the upper and lower rollers.

2.This machine consists of two major parts: the working part and the transmission part on the welded integral chassis. The working part consists of left and right roller bearing seats, an upper roller, two lower rollers (the three rollers are made of 45# forged round, tempered, and medium-frequency heat treated), a lifting screw worm gear pair, and some auxiliary parts. The lower roller is the main drive roller, the upper roller is the passive roller, and the upper roller can be adjusted up and down along the height direction. The transmission part consists of the main motor, the main reducer and other auxiliary parts.

3.The transmission of the lower roller is realized by the main motor through the main reducer. The output shaft of the main reducer is transmitted to the two lower rollers through a set of gears. The change of the roller rotation direction is obtained by the reversing of the main motor.

4.The lifting and lowering movement of the upper roller is realized by the auxiliary motor driving the worm and worm gear mechanism under the left and right roller bearing seats through the auxiliary reducer, so that the nut fixed on the worm gear rotates, thereby moving the lifting screw up and down. The lifting transmission device is a copper worm gear and a copper nut.

5.The unloading device is designed to remove the workpiece after the cylindrical part is rolled. Before unloading, the upper roller rises to its position first, and the balance pull rod is used to pull the upper roller at the tail end of the upper roller, and then the pin on the tilting bearing seat is pulled out, and the tilting bearing seat is overturned. The rolled workpiece can be removed from one end of the upper roller.

Main purchased parts

| Description | Supplier |

| Composite bearings | Jiashan Oil-free Self-lubricating Bearing Factory |

| Working roller | Nangang/Jiangyin No. 2 Forging/Daye |

| Main motor | Siemens Beide Motor |

| Main electrical components | Suzhou Electric |

| Main reducer | Tailong/Taixing |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life