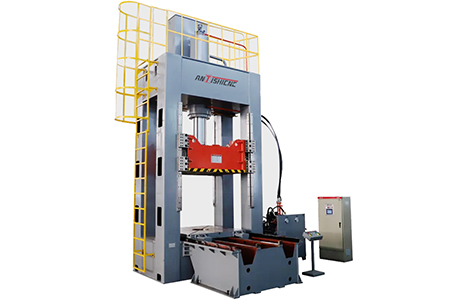

YQ34-400T Frame Structure Hydraulic Press Machine

Maximum liquid pressure:25Mpa

Pressing Force:4000Kn

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Project | YQ34-400T |

| Maximum liquid pressure (Mpa) | 25 |

| Pressing Force(Kn) | 4000 |

| Slider stroke (mm) | 700 |

| Maximum opening height (mm) | 1100 |

| Table size (mm) | 1500*1800 |

| Down speed of empty range (mm / S) | 180 |

| Working speed (mm / S) | 9-20 |

| Return speed (mm / S) | 130 |

| Motor power( kw) | 22*2 |

| Hydraulic pad tonnage (T) | 100 |

| Hydraulic pad stroke(mm) | 300 |

| Hydraulic pad area (mm) | 1100*1400 |

| Mobile workbench size (mm) | 1500*1800*90 |

| Machine weight (T) | 38 |

Resources & Downloads:

YQ34-400T Frame Structure Hydraulic Press Machine Product Introduction :

ANTISHICNC company produced 400T frame hydraulic press, also known as 400-ton frame hydraulic press, is a type of 400T hydraulic press series with a nominal force of 4000KN. It is widely used in forming, punching, manufacturing of automotive parts, and pressing of powder metallurgy. It is also suitable for pressing processes of various plastic materials, such as stamping, bending, turning, etc. It can also be engaged in correction, pressing, grinding wheel forming, plastic products, and rubber products.

The body of the 400T frame hydraulic press adopts computer optimized design, a full steel plate welded frame structure, four-corner and eight-sided right-angle guide rails, high precision, good rigidity, and hydraulic pre-tightening. The hydraulic system adopts a two-way plug-in integrated valve; the entire system works stably and reliably, has a long service life, less leakage, and fewer fault points. The electrical system is controlled by a “PLC” programmable controller, and can be configured with proportional pressure regulation, stroke digital display, photoelectric protection device and mobile workbench (convenient for mold replacement) according to user requirements.

Performance characteristics of 400T frame hydraulic press:

1.The fuselage adopts computer optimized design, and the frame structure is welded with all steel plates, which has good precision retention;

2.The hydraulic control adopts a cartridge valve integrated system, which reduces leakage points, reliable operation and long service life;

3.It can realize two molding processes of fixed pressure and fixed stroke, with pressure holding delay function, and the delay time is adjustable;

4.Four-corner and eight-sided guide rails, high guiding accuracy, strong anti-eccentric load ability, and centralized lubrication;

5.The slider is fast and the work efficiency is high;

6.It can be equipped with a mobile workbench, punching buffer device, photoelectric protection device, punching device, slider safety bolt, etc.

400T frame hydraulic press is an energy-saving and efficient hydraulic press that uses a servo motor to drive the main transmission oil pump, reduce the control valve circuit, and control the hydraulic press slider. Compared with ordinary hydraulic presses, the overall control does not contain proportional servo valves or proportional pumps. The servo-driven hydraulic press has the advantages of energy saving, low noise, small temperature rise, good flexibility, high efficiency, and convenient maintenance. It can replace most existing ordinary hydraulic presses and has a broad market prospect. Compared with traditional hydraulic presses, the energy-saving effect is significant. Depending on the processing technology and production rhythm, the servo-driven hydraulic press is more energy-saving and power-saving than the traditional hydraulic press.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life