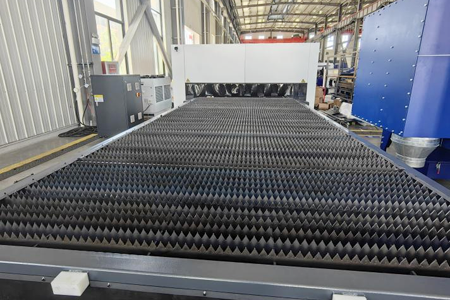

AT-6025HF Full Cover 12kw Fiber Laser Cutting Machine

Processing format (L*W) : 6000×2500mm

X-axis travel:6000mm

Y-axis travel : 2500mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Processing format and scope of work | AT-6025HF-12KW |

| Processing format (length*width) | 6000mm×2500mm |

| X-axis travel | 6000mm |

| Y-axis travel | 2500mm |

| Precision | |

| X, Y axis positioning accuracy | X-axis 0.1mm/m;Y-axis 0.06mm/m |

| X, Y axis repeat positioning accuracy | X-axis 0.04mm;Y-axis 0.02mm/m |

| Speed | |

| X/Y axis max. linkage positioning speed | 140m/min |

| Max. acceleration | 1.5G |

| Power parameters | |

| Number of phases | Three-phase five-wire |

| Power supply rated voltage | 380V |

| Frequency | 50 HZ |

| Weight and Dimensions | |

| Average load of workbench | 11775kg |

| Other | |

| Workbench Exchange | Parallel to pull |

| Exchange Time | Within 30S |

Resources & Downloads:

AT-6025HF Full Cover 12kw Fiber Laser Cutting Machine Product Introduction :

Product Details

X6025-12KW Swing Lightning fiber laser cutting machine is currently one of the laser cutting machines with the best performance matching and the highest cost performance in the world, and it is also the best-selling laser cutting machine in China. Our company cooperates with the Italian SmartCae Center to optimize and upgrade the bed, and uses the Nastran Sol200 Protocol system to conduct simulation analysis. The dynamic performance of the bed has been significantly improved, meeting the dynamic response requirements of a moving speed of 140 m/min and an acceleration of 1.5 g. More than 90% of the main configuration of the whole machine adopts imported well-known brands (see the equipment configuration list for details). Equipped with a high-power dedicated laser cutting head, it supports efficient and stable cutting for a long time and ensures the continuity of production for users. Equipped with Smart Manager special CNC software to optimize various punching modes, and adopt a new generation of leapfrog management method, the movement is smoother and the cutting efficiency is ahead of the peers. The equipment also has a unique cutting process database, which can realize fast perforation, ultra-fast cutting of medium and thin plates, fine cutting, bright surface cutting and other cutting needs. In addition, the limit cutting of thick plates can reach 70mm.

X6025-12KW The fiber laser cutting machine is equipped with first-class configuration, and its overall performance, cutting precision, cutting efficiency, cutting yield and sheet metal utilization rate are all ahead of other cutting machine manufacturers in China. It is the first choice for laser users.

European quality, high cost performance

X6025-12KW the manufacture and inspection of CNC laser cutting machines all implement European standards. The products have passed ISO9000 quality system certification, CE certification and many other professional assessments, and obtained more than 20 patent certificates, filling many technical gaps in China. The product performance is stable and reliable. It has reached International advanced level.

High cutting efficiency, low operating cost

X6025-12KW fiber laser cutting machine has high production efficiency and low cost of use, which are mainly manifested in the following five aspects:

1. High photoelectric conversion efficiency, low power consumption

Fiber lasers generate less heat and manage the heat generated more effectively. The quantum defect (i.e. the difference between the pump energy and the generated energy) of the Ytterbium-doped diode-pumped fiber laser (the pump wavelength is 980 nm) is lower than that of the Nd-doped YAG diode-pumped laser (the pump wavelength is 808 nm).

In addition, the light-to-light conversion efficiency of fiber lasers is usually 70-80%, while pumped YAG is only about 4%, and semiconductor pumped YAG and disk lasers are about 40%. Since the laser is always contained in the fiber, there are no other factors that cause laser loss in the laser cavity.

2.High-speed cutting, fast perforation

The acceleration of X6025 fiber laser cutting machine is as high as 2.0G, and the maximum moving speed can reach 160m/min. It can realize high-speed and stable cutting even on the 6025 format. It can be equipped with 12000W, 15000w, 20000w, 30000W lasers. Compared with other Chinese manufacturers, Feiyue’s fast piercing function is another highlight. The 20KW model only needs 0.8 seconds for 30mm carbon steel, 0.2 seconds for 16mm-25mm carbon steel, and 0.1 second for piercing below 14mm.

3. Efficient cutting

X6025 fiber laser cutting machine professional sheet metal cutting numerical control system, with focal length digital display function, lens drawer replacement function, fast automatic exchange table function, automatic edge finding and positioning function, breakpoint return function, perforation control function, laser energy A series of powerful functions such as adaptive control function, stable Z-axis floating function, leapfrog function, expert parameters, etc., effectively guarantee the cutting efficiency and quality.

4.Automatic programming nesting software is powerful

Spanish Lantek professional laser cutting nesting software can realize automatic programming, nesting, layout, word processing, process setting, etc., which maximizes the utilization rate of sheet metal and the convenience of nesting.

5. Low maintenance cost

The laser equipped on the X6025 model can choose to shield some power modules in case of maintenance and failure, and some modules continue to work, so as to minimize the loss caused to customers due to equipment failure and ensure the continuity of production.

Our advantage

After more than 30 years of development, the technical advantages are mainly reflected in equipment stability, cutting process, cutting efficiency and numerical control system, etc. Under the same conditions, the X6025 Swing type laser cutting equipment is at least 30%-50% faster than the whole board cutting efficiency of the same industry, and now it has been obtained Market inspection and customer recognition. At the same time, with the improvement of the technological revolution in the laser power section, we and Atlas jointly developed a clean air package, which is used for high-power equipment to increase the thickness of the air cutting, almost without burrs; with German Press The special joint development of 20000W-40000W special cutting head – Prey cutting head, subverts the new technology of the industry. At present, the cutting head is the exclusive product of our company.

1. How is the cutting process different from other manufacturers?

Our cutting equipment has its own independent and complete process database, including: carbon steel oxygen (common cutting and bright surface cutting), nitrogen, air cutting; stainless steel nitrogen (standard cutting and low pressure cutting (throttle cutting)), air cutting ; Nitrogen, air cutting of aluminum, nitrogen cutting of brass and oxygen cutting parameters of copper. The ANTISHICNC cutting process adds small hole and sharp corner cutting parameters, fast perforation parameters, common cutting and fast cutting parameters for carbon steel within 30mm, air cutting parameters for various materials, and some unconventional cutting parameters, such as nitrogen and air for carbon steel Cutting, special nozzle cutting parameters and stable pre-piercing cutting parameters.

2.Compared with other domestic manufacturers, what are the superior technologies of our laser cutting equipment?

(1)Thick plate bright surface cutting technology: the laser bright surface cutting process of processing thick carbon steel plate through high focus, high power, supersonic nozzle.

(2)Thick plate small hole cutting technology: realize cutting holes with a diameter less than 1/2 on thick plates, breaking the traditional concept that the diameter of the cut hole is equal to the thickness of the plate.

(3)Low-pressure cutting technology: Using ANTISHICNC’s original supercharged nozzle to increase the utilization rate of gas flowing through the slit under low pressure to achieve low-pressure cutting. The advantage is that the gas consumption is reduced by 40% and the speed is increased by more than 30%.

(4)Corner cutting function: commonly used in carbon steel right-angle leads, etc.

(5)Ultra-fast + cutting technology: it is a combination of flying perforation and original ultra-fast, so that ultra-fast cutting is not limited to thin plate processing, and at the same time, it does not block the nozzle and protect the lens during normal processing.

(6)Carbon steel nitrogen air cutting: It is two methods of high-efficiency and low-cost processing of carbon steel, especially air cutting, whose cutting speed is 3-6 times that of oxygen cutting.

(7)Contact gas-saving nozzle cutting technology: it is that the center gas cover of the nozzle is in contact with the surface of the processed plate, so that all the gas can pass through the slit, which greatly improves the utilization rate of the gas.

(8)Water-cooled cutting technology: it sprays water while cutting, and is used for carbon steel cutting. It is mainly aimed at graphics with relatively dense processing parts and relatively large heat generation, so as to prevent processing instability or failure due to thermal influence during the heating process. One of the unique technologies.

(9)Slag-free perforation technology: Utilize the advantages of multi-layer perforation in SmartManager to optimize the perforation of thick stainless steel so that there is no slag on the surface of the material after piercing. The advantage is that it can complete the stable cutting of small holes on thick stainless steel without stopping.

(10)Frequency conversion piercing technology: use the frequency duty cycle to improve the process, and realize fast and stable piercing during piercing. During the piercing process, the sound of piercing can be heard from high to low.

(11)Scanning and printing technology: Laser processing of pictures can be realized on the cutting machine. One of our unique technologies can scan and print a QR code that can be recognized by a mobile phone on the workpiece.

(12)Influence the nesting process: take pictures of the remaining materials through the high-definition camera, and then typesetting and cutting on the remaining materials, which greatly improves the utilization rate of the remaining materials and saves the time of manual typesetting.

(13)Focus compensation technology: With the continuous increase of laser power, the phenomenon of focus drift becomes more and more obvious. This is caused by the optical lens in the cutting head and cannot be avoided. Focus drift will lead to instability and inconsistency in the cutting process, and in order to ensure the cutting, the cutting speed must be reduced to make up for it. For this phenomenon, the focus compensation technology can make up for this very well. It not only ensures the full-page The stability and consistency of cutting can also play the cutting speed that high power should have. One of our exclusive technologies.

(14)Rapid gas exchange technology: This technology mainly realizes the rapid switching of different gases on the same cutting workpiece, so as to ensure the efficiency and quality of perforation while ensuring that the cutting is not affected.

(15)Thunder cutting technology: The cutting speed of medium and thick plates is fast and the efficiency is high. In the same power range and the same thickness, the average cutting efficiency of Thunder is more than 50%. Slag-free cutting of aluminum alloy medium and thick plates, that is, the cutting of aluminum alloy plates within 8mm is basically slag-free, fine cutting, the smallest hole can be cut with a diameter of 0.2mm, and 1mm small holes can be cut on 8mm aluminum alloys. Cutting is basically slag-free, unique One of the techniques.

What are the advantages of our CNC system compared with other manufacturers in the market?

1. The operation interface is simple, and the function list is clear at a glance, allowing novices to get started quickly.

2. There are many perforations, leads, and cutting layers. For complex graphics, multiple different process parameters can be used to achieve high-quality cutting.

3. The processing time of the parts is calculated in advance, just import the workpiece, and then select the corresponding cutting parameters to get the cutting time of the entire workpiece without waiting for the cutting to be completed.

4. The breakpoint return function has a wide range and is convenient and accurate. You can choose to start from the upper or lower contour of the cutting loss, or how many millimeters before and after the lost point, or directly start from the starting point of the lost contour.

5. Auxiliary cutting air pressure, focus and other feedback prompts, you can clearly see the accurate cutting air pressure, focus, etc. from the interface at that time, which is helpful for problem judgment or process adjustment.

6. Simple typesetting, scaling, etc. can be directly performed on the CNC.

7. With absolute coordinates (or absolute height), it is convenient to control the cutting height.

8. Cutting head anti-collision function.

Improvements to our laser CNC software

(1) Faster control and sampling frequency, optimized control method, effectively avoid plate smashing, friction nozzle, cutting vibration problems, and greatly improve processing efficiency.

(2) Optimize the function of avoiding obstacles, and actively prevent the collision of the cutting head more effectively.

(3) Flying piercing, significantly improving the efficiency of sheet metal processing.

(4) Hide process parameters, help customers keep process secret, and improve market competitiveness.

(5) Water-cooled cutting technology can effectively improve the processing quality.

(6) Touch Down nozzle support improves processing quality while reducing gas consumption costs.

(7) Influence nesting and realize fast processing of “what you see is what you get”.

(8) Support large screen, improve user experience operation, and integrate software monitoring function to reduce hardware cost.

(9) One-key recovery on the large screen to help customers recover the system quickly.

(10) Large-screen monitoring software directly displays the status of key components such as cutting heads and lasers.

(11) Remote operation and maintenance, to help monitor customer equipment after sales, to achieve more convenient and faster after-sales service.

(12) MINIMES software program development helps users to transmit processing files remotely, monitor machine status remotely, and help customers manage workshop processes and monitor remotely with mobile phones.

(13) Flying cutting, synchronous ultra-fast cutting.

(14) Automatic nozzle cleaning, which can automatically clean the nozzle during laser processing.

(15) Job statistics, developed and perfected cutting job statistics.

(16) Number of perforated layers: increased from 4 layers to 18 layers.

(17) Practical functions: terminal edge micro-joint, numerical control compensation, manual panel cutting, cutting range inspection.

| Specification | Quantity | Supplier |

| Laser | ||

| 12000W fiber-optic laser | 1 set | ChuangXin MAX-12000W |

| Cutting head | ||

| Laser cutting head | 1 set | laser Penta Laser million watt cutting head penta cutting head |

| Cutting signal | 1 set | Italy EL.EN |

| Second Generation Super Cooling | 1 set | Vortex cooling device |

| Machine tool host | ||

| Machine tool mechanical platform and accessories | 1 set | Laser |

| X, Y, W axis rack | 1 set each | Germany STRRONSE |

| Linear Guides | 1 set each | Taiwan HAWKKING |

| reducer | 3 sets | Japan DESBORE |

| Gas pressure reducing valve | 2 sets | GENTEC |

| CNC and software system | ||

| CNC system (including control software) | 1 set | Imported a full set of dual PC Italian lightning system smart Manger (Italy EI.En) touch screen operation is more smooth |

| AC Servo Motor and Driver | 4 sets | Inovance INOVANCE |

| Nesting software | 1 set | Spain LANTEK |

| Laser Cutting Process Database | 1 set | Italy El.En Group |

| Standard accessories | ||

| Exchange workbench | 1 set | ANTISHICNC Laser |

| Chiller | 1 set | DVT |

| Slagging device | 1 set | ANTISHICNC Laser |

| Exhaust system | 1 set | ANTISHICNC package |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life