Fully Automatic Pipe Bender DW89CNC-2A-1S

Max. bending radius: R400mm

Minimum bending radius: R≧1.5D

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | DW89CNC-2A-1S | Remark | |

| Maximum bending pipe diameter ×Wall thickness | Φ89mm×6mm | 1. The minimum bending radius is based on the diameter of the pipe. 2. Maximum bending radius can be according to customer requirements. 3. The maximum core length can be according to customer requirements. |

|

| Carbon steel pipe | |||

| Maximum bending radius | R400mm | ||

| Minimum bending radius | R≧1.5D | ||

| Maximum bending Angle | 190° | ||

| Maximum feeding length | 2700mm | ||

| Feeding method | Direct delivery | ||

| Clip | |||

| Working speed | Bending speed | Max 40°/s | |

| Tubing speed | Max 160°/s | ||

| Feeding speed | Max 800mm/s | ||

| Working accuracy | Bending accuracy | ±0.1° | |

| Tubing accuracy | ±0.1° | ||

| Feeding accuracy | ±0.1mm | ||

| Information input mode | 1. coordinate(X . Y. Z) | ||

| 2. Working value(Y. B. C) | |||

| Bend way | Hydraulic bending | ||

| Corner servo motor | 1.5kw | ||

| Feed servo motor | 2kw | ||

| Pipe fittings allow elbows | 50 | ||

| Number of parts that can be stored | 500 | ||

| Oil motor power | 11kw | ||

| Maximum system pressure | 12 Mpa | ||

| Machine dimensions | 5000 x 1200 x 1500mm | ||

| Machine weight | 2800kg | ||

Resources & Downloads:

Fully Automatic Pipe Bender DW89CNC-2A-1S Product Introduction :

Features

1.A touch screen display, CNC computer operation, can store 500 sets of memory.

2.Rebound compensation value setting procedures, procedures and processing data security functions.

3.Corner, feeding, bending are servo controlled.

4.The operating system is equipped with password, key, and quantity and time record for production management.

5.It has the function of slow bending and slow core pulling.

6.Error messages are displayed on the screen to help the operator clear them immediately.

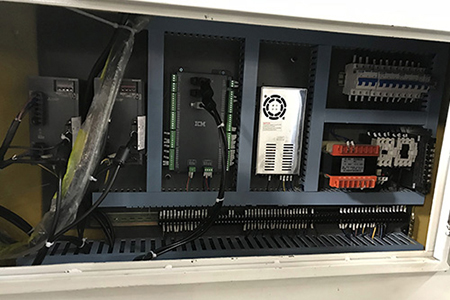

Main Parts for the machine

| Name | Specification | Supplier |

| Hydraulic motor | 11KW | China |

| The oil pump | PVL1-25 | China |

| Pressure valve | 02W | Taiwan’s seven ocean |

| Solenoid valve | G02-2C-DC24 | Taiwan’s seven ocean |

| The overflow valve | 2B3B-D24 | Taiwan’s seven ocean |

| Sealing ring | / | Taiwan CHO |

| Pressure gauge | 0-25Mpa | China |

| AC contactor | LCED1801 | Taiwan TAIAN |

| touch screen | 10 inch | China |

| Switching power | 24V | Taiwan MEAN WELL |

| Corner servo motor | 1.5KW | Japan MITSUBISHI |

| Feed servo motor | 2KW | Japan MITSUBISHI |

| Smart transformer | SG-3K | China |

| Linear Guide | 25*3100 | Taiwan |

| Corner reducer

Feed reducer |

1.AF120-40

2.AF160-10 |

Taiwan |

| Central controller | ICM-880W02 | China |

| Relay | / | China/Japan MITSUBISHI |

| thermal relay | LR-16B | Taiwan TAIAN |

| Induction switch | 24V | China |

Remark:The accessories in the configuration list allow the manufacturer to change the accessory brand to a higher level according to the material supply. Users can purchase other brand accessories according to their needs.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life