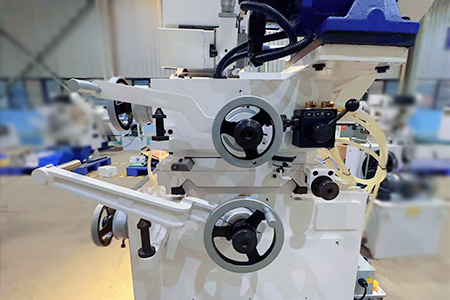

FX-12S High Precision Centerless Grinder

workbench dia. : 0.5 - 40 mm

Grinding wheel size :

305x150x120 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| ITEM | UNIT | FX-12S | |

| 1 | Standard workbench working diameter | mm | ¢ 0.5—40 |

| 2 | Grinding wheel size (outer diameter x width x inner diameter) | mm | ¢305x150x120 |

| 3 | Adjust wheel size (outer diameter x width x inner diameter) | mm | ¢205x150x¢90 |

| 4 | Grinding wheel speed | rpm | 1950 |

| 5 | Adjust wheel speed | rpm | 0-320 |

| 6 | Wheel drive motor | kw | 5.5 |

| 7 | Adjusting wheel drive motor | kw | 2.0 |

| 8 | Hydraulic pump drive motor | kw | 0.75 |

| 9 | Cooling pump drive motor | kw | 0.37 |

| 10 | Adjust wheel feed hand wheel | mm | 3.5mm / turn 0.02 / scale |

| 11 | Adjustment wheel fine adjustment hand wheel | mm | 0.1mm/rev 0.001/scale |

| 12 | Worktable feed hand wheel | mm | 7mm / turn 0.05 / scale |

| 13 | Workbench fine-tuning handwheel | mm | 0.2mm/rev 0.001/scale |

| 14 | Trimming feed hand wheel | mm | 1.5mm / turn 0.01 / scale |

| 15 | Adjust wheel tilt angle | degree | ±5 – 3 |

| 16 | Adjust the angle of rotation of the wheel | degree | ±6 |

| 17 | Mechanical Dimensions | mm | 1800x1400x1450 |

| 18 | Packing size | mm | 2350x1650x1770 |

| 19 | Mechanical weight | kg | 1700 |

| 20 | Packing weight | kg | 1850 |

Resources & Downloads:

FX-12S High Precision Centerless Grinder Product Introduction :

Product introduction

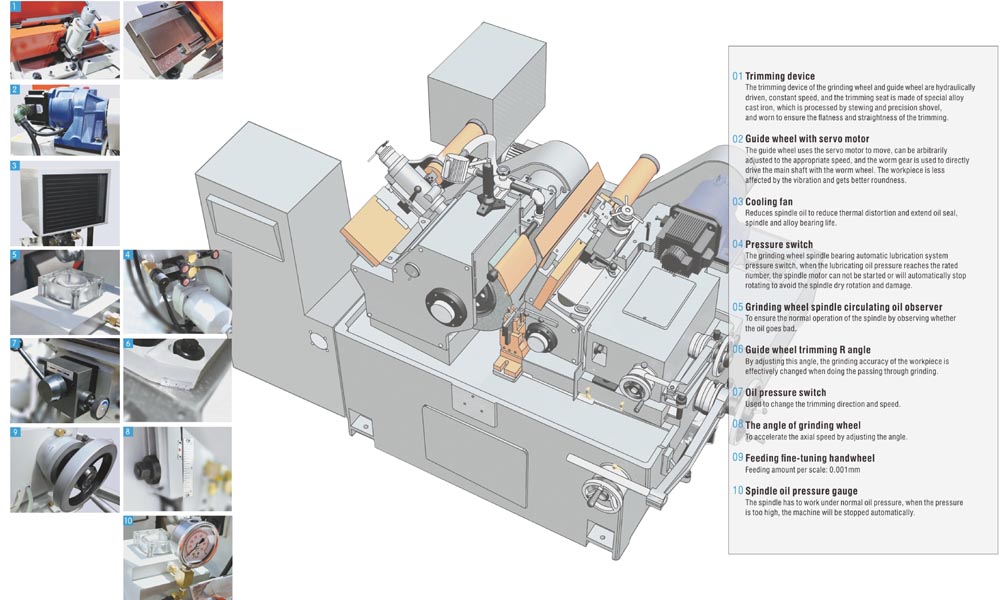

Centerless grinding machine is a type of grinding machine that does not need to use the axis of the workpiece for grinding. It is mainly composed of three mechanisms: grinding wheel, adjustment wheel and workpiece support. The grinding wheel actually performs the grinding work, and the adjustment wheel Control the rotation of the workpiece and control the feed speed of the workpiece. As for the workpiece holder, which supports the workpiece during grinding, there are several ways to cooperate with these three parts, except for stopping grinding, the principle is the same.

There are two main grinding methods for centerless cylindrical grinders: through type and plunge type; through type centerless grinder, the workpiece is fed along the axis of the grinding wheel for grinding, and the small inclination angle of the guide wheel axis is adjusted to realize the axial feed of the workpiece. It is suitable for grinding slender cylindrical workpieces, short shafts without central holes and sleeve workpieces. The plunge-type centerless grinding method is that there is an axial positioning fulcrum on the pallet, the workpiece is supported at a certain position on the pallet, and the grinding wheel or guide wheel is used for grinding. For grinding workpieces with shoulders or bosses as well as cones, spheres or other workpieces of revolution. “Plung-in” to “Through-through” centerless grinding is a composite grinding method of the two centerless grinding machines.

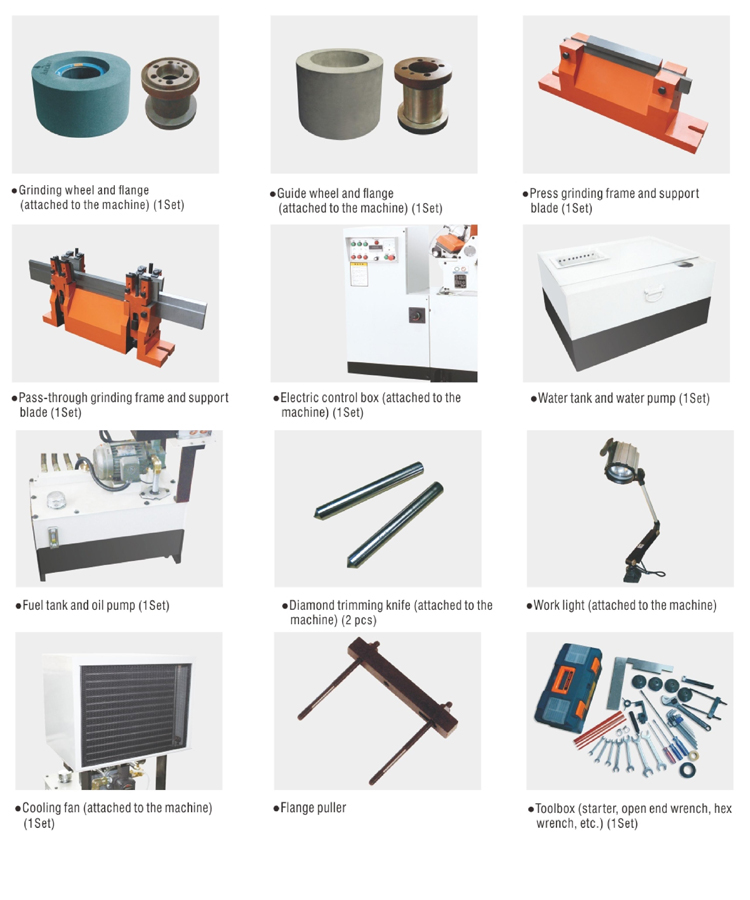

Standard Equipment

Optional Equipment

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life