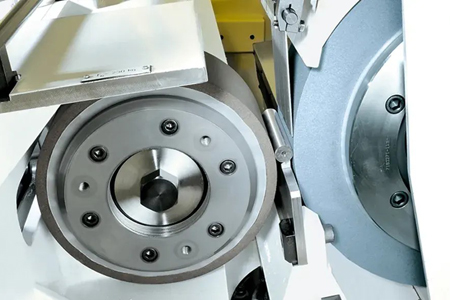

L600 High Precision Large grinding diameter wide-wheel CNC high efficiency centerless grinder machine

Grinding diameter : 10~250mm

Grinding length : 590mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

|

Technical Data

|

L600

|

|

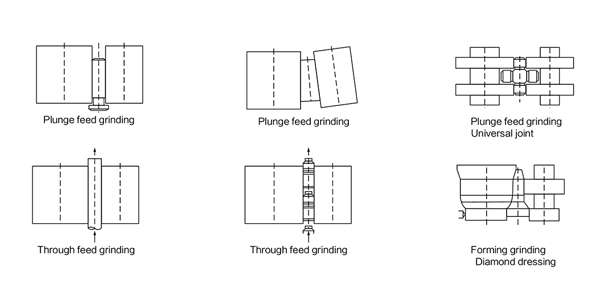

Plunge-feed

|

|

|

Grinding diameter

|

10~250mm

|

|

Max grinding length

|

590mm

|

|

Through-feed

|

|

|

Grinding diameter

|

10~250mm

|

|

Grinding wheel specification

|

P600x600x305mm

|

|

Regulating wheel specification

|

P350x600x203mm

|

|

Grinding wheel speed

|

llOOr/min

|

|

Regulating wheel speed(stepless)

|

10~200r/min

|

|

Regulating wheel frame swivel angle

|

|

|

Vertical

|

-2° ~ +5°

|

|

Horizontal

|

-l°~+3°

|

|

Grinding wheel min feed amount

|

0.001mm

|

|

Regulating wheel min feed amount

|

0.001mm

|

|

Grinding wheel dresser min feed amount

|

0.001mm

|

|

Height from centerline of gri.wheel & reg.wheel to workrest

|

260mm

|

|

Water flow

|

200L/min

|

|

Total power

|

|

|

Grinding wheel motor

|

45kw/55kw

|

|

Regulating wheel motor

|

5.5kW

|

|

Power supply

|

3N 50HZ 380V

|

|

Machine dimension(L*W*H)

|

4400*4300*1700mm

|

|

Machine weight

|

About 12000kg

|

|

Accuracy (Standard bars)

|

|

|

Roundness

|

0.001mm

|

|

Cylindricity

|

0.0018mm

|

|

Roughness

|

Ra0.16μm

|

Resources & Downloads:

L600 High Precision Large grinding diameter wide-wheel CNC high efficiency centerless grinder machine Product Introduction :

Product Features:

1. Grinding configuration & regulating area.

Grinding wheel frame and regulating wheel frame double moving.

Iron casting, natural aging, high rigidity, minimum deformation.

The diameter and wideth of grinding wheel is 600mm, with strong grinding force, can increase the grinding allowance in a single pass, and decrease repeating, to raise efficiency.

Grinding wheel inverter constant linear velocity guarantee reliable grinding.

Spindles of grinding wheel & regulating wheel adopt five-plate short bearing bushed static-hydrodynamical oil film bearing, which with better rigidity,and meet the need of heavy loading grinding and precise grinding. Grinding wheel & regulating wheel double supporting.

2. Feeding & dressing

Grinding wheel frame feeding guide is flat V type paste to mould rail, servo motor drives ball screw, minum feeding amount is 0.001mm.

Regulating wheel feeding guide is flat V type paste to mould rail, servo motor drives ball screw, minum feeding amount is 0.001mm.

Grinding & regulating wheel dresser reciprocate adopts linear guide, gear motor, step-less speed adjustiing.

Grinding wheel dresser feeding adopts double V roller guide, servo motor drives ball screw. Regulating wheel dresser feeding adopts double V roller guide, gear motor step-less speed adjusting.

3. Electric

Regulating wheel adopts inverter step-less speed adjusting, avoiding motor reverse.

Operation system adopts Siemens 808D three axes CNC system with automatic infeed grinding system, feeding amount, speed, time and step adjustable.

4. Lubrication

Separate lubrication oil tank for grinding wheel spindle and regulating wheel spindle with constant temperature.

5. Cooling

Cooling system adopts magnetic separator.

Configuration

Modularization design, scientific and good looking appreciate, optional if necessary.

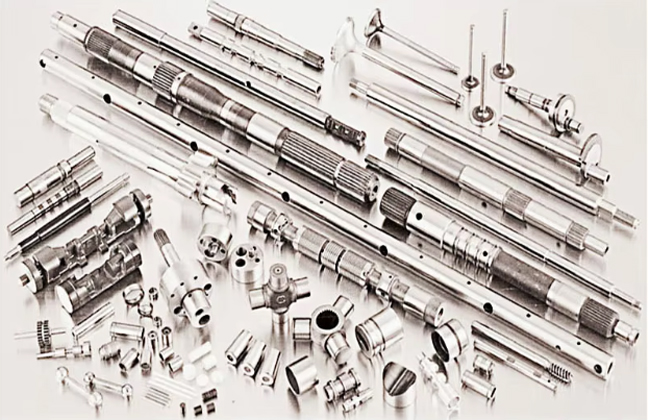

Main application: The grinder is mainly used for through-feed grinding of cylindrical surface of ring-type parts and bearings, which diameter of 10-250 mm.

Grinding Examples

Operation Applications

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life