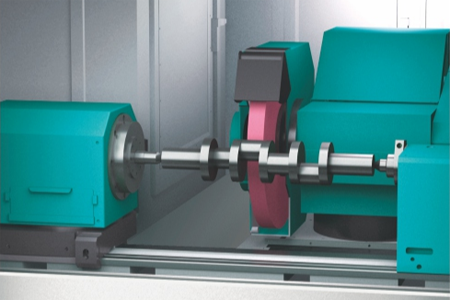

GP-32 Eccentric Shaft Crankshaft Special-Shaped Long Shaft Grinder

Max rotating dia. : Φ380mm

Max grinding dia. : Φ320mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| ITEM | Technical parameter |

| Working scope | |

| Height of Center | 200mm |

| Maximum rotating diameter | Φ380mm |

| Maximum grinding diameter | Φ320mm |

| Grinding length between two tops | 600mm |

| Rotary Table( Model 600) | ﹢6°/-9° |

| Maximum pedestal between two tops | 60kg |

| Grinding carriage | |

| Rotable Angle range (manual) | ±15° |

| Grinding wheel spindle type | Dynamic and static pressure grinding wheel spindle (standard with oil cooling) |

| Wheel spindle speed range | 1650/1850/2100rpm |

| Standard grinding wheel size (φ×W×B) | Φ450×38-50×127mm |

| Special grinding wheel size (φ×W×B) | Φ510×50-80×203mm |

| Wheel spindle motor power | 3.75KW/5.5KW(special) |

| Maximum linear speed of grinding wheel | 45m/s |

| Grinding wheel spindle cooling method | Oil cooling |

| Workpiece direct drive head stock | |

| Speed range stepless speed regulation | 0-600rpm |

| Taper of spindle taper | MT-4 |

| Tooling adapter set model | MT-4 |

| Workpiece head rotation angle range | ﹢15°/-15° |

| Maximum clamping load (with tooling) | 150Nm |

| Permanent magnet synchronous motor power(S1-100%/KW) | 3KW |

| Continuous rated output torque(S1-100%/A) | 47.8Nm |

| Encoder brand | Renishaw |

| Spindle cooling method | Water cooling |

| Repeated positioning accuracy of head stock rotation | ±2arcsec |

| Taper hole runout at shaft end | ≤0.001 |

| Spindle end face beating | ≤0.002 |

| Axial rigidity(N/um) | ≥500 |

| Radial rigidity(N/um) | ≥400 |

| Head stock movement method | Manual standard air floatation |

| Tail stock | |

| Sleeve diameter | Φ50mm |

| Sleeve stroke | 32mm |

| Morse taper | MT-4 |

| Tailstock movement method | Manual standard air floatation |

| Wheel carriage feed-X axis (linear motor) | |

| X axis maximum stroke | 350mm |

| X axis linear motor maximum thrust | 1044-4271N |

| X axis linear motor acceleration | ≤0.2G |

| X axis maximum feed rate | 15m/min |

| HPG (electronic handwheel) minimum feed | 0.0001mm |

| Programmable minimum feed | 0.0001mm |

| Minimum resolution of HEIDENHAIN incremental encoders | 0.0001mm |

| X axis feed positioning accuracy | ≤0.0016mm |

| X axis feed repeat positioning accuracy | ≤0.0014mm |

| ITEM | Technical parameter |

| Z axis for table feed (servo motor) | |

| Z axis stroke (600 type) | 600mm |

| Z axis servo motor power | 2.2KW |

| Z axis maximum feed rate | 12m/min |

| HPG electronic handwheel minimum increment | 0.0001mm |

| Programmable minimum feed | 0.0001mm |

| Min. resolution of HEIDENHAIN incremental grating ruler (optional) | 0.0005mm |

| Control System | |

| CNC system | Lynuc CNC |

| software | Graphical interactive interface |

| Display screen | 10.4 inch TFT color display |

| keyboard | full keyboard |

| RAM | 3Gb (1Gb users) |

| Number of control axes | Can control up to 7 axes |

| interface | USB/Ethernet/RS232 |

| Machine Tool Electric | |

| Standard 3-phase power supply | 380V 3ph 20Hz |

| Control circuit voltage | 110vAC/24vDC. |

| Input voltage deviation range | ﹢/-10% |

| Full load power consumption (host) | 36KVA |

| Pneumatic supply | |

| Enter air pressure | 5.5bar |

| Request flow | 40-50l/min |

| Air source standard | BS ISO 8573-1:2001 |

| Environmental parameters | |

| Standard machine noise | <75dB(A) |

| Ambient temperature | 0-40℃ |

| Environment humidity | ≤75% |

| Other | |

| Floor space size | 3800×2120mm×2000 |

| Height | 2170mm |

| Net weight | 5440kg |

Resources & Downloads:

GP-32 Eccentric Shaft Crankshaft Special-Shaped Long Shaft Grinder Product Introduction :

Product description :

Basic technical parameter

1. Center height/maximum grinding diameter: 170/320mm

2. The distance between two centers: 600mm

3. The maximum work-piece weight between the two centers: 60kg

4. Maximum diameter of grinding wheel: standardφ450mm

5. X axis (linear motor) stroke/fast traverse speed: 350mm/15m/min

6. X axis (linear motor) thrust: 1044–4272N

7. Z axis (servo motor) stroke/fast traverse speed: 600mm/12m/min

8. The minimum resolution of X axis/Z axis is 0.0001mm

9. Direct drive work-piece head stock spindle Spindle brand/motor type/encoder brand: Guangzhou Haozhi/Permanent Magnet Synchronous Motor/Renishaw

10. Direct drive work piece head stock spindle (C axis) maximum speed / repeat positioning accuracy: 600rpm/±2arcsec

11. Direct drive work piece head stock spindle (C axis) rated output torque/shaft end taper hole run out: 47.8Nm/0.001mm

12. Brand/Type/Line Speed of Grinding Wheel Spindle: Guangzhou Haozhi/Dynamic and Static Pressure Wheel Spindle/40m/sec

13. Numerical control system: LYNUC

Product features :

1. Stable and reliable-super rigid structure excellent precision performance;

2. The machine tool has been tested under the most severe environments and conditions, and has outstanding accuracy retention. It is suitable for the requirements from single-piece to mass production and is widely used in special-shaped grinding and non-circular grinding industries;

3.Outstanding performance-excellent performance for processing special-shaped parts;

4. High precision, high rigidity, and high efficiency are the basic characteristics of this grinder, achieving a perfect combination of performance and efficiency;

5. Due to the excellent performance and flexible design of the machine tool, it can be widely used in various industries such as aviation, medical, hydraulic, mold, core parts of robot reducer, and auto parts;

6. Easy to operate-easy to use operating system;

The latest generation of user-friendly graphical programming software has simple and fast settings and an intuitive user interface. It does not require the operator to enter complex codes and subroutines. The operation is simple and easy to learn, making programming and setting faster. The user experience and operation experience are extraordinary;

Stand Equipment

1. Standard grinding fluid supply system

2. External grinding wheel, φ450mm 1 pc

3. External grinding wheel flange, φ127mm 1

4. Mohs No. 4 full center and half center each

5. One set of workpiece drive dial (sweet chuck)

6. 1 standard gold fountain pen

7. Standard grinding and dressing cycle

8. Hydrostatic spindle oil cooling system

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life