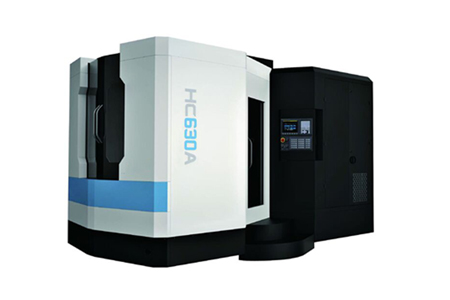

HC Series Horizontal Machining Center

HC500A / HC630A

HC800A

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model Parameters | HC500A | HC 630A | HC800A |

| Table Size (mm) | 500×600 | 630×630 | 800x 800 |

| Max Loading Weight (kg) | 500 | 1500 | 3000 |

| Number-width x distance (mm) | 6x 14x 80 | 5x18x125 | 5x22x160 |

| XY/Z Travel (mm) | 800/600/600 | 1000/800/900 | 1200/900/900 |

| Rapid speed(X /Y /Z) m/min | 15/12/15 | 15/12/15 | 15/12/15 |

| X Y Z cutting speed (mm/min) | 1 ~ 5000 | 1~ 5000 | 1 ~ 5000 |

| Spindle center line to table surface (mm) | 50~ 650 | 0~ 800 | 0~ 900 |

| Spindle nose to table center (mm) | 150~ 750 | 200~ 1100 | 200~ 1100 |

| Spindle speed ( rpm ) | 6000 | 6000 | 6000 |

| Spindle power ( kw) | 11/15 | 15/18.5 | 18.5/22 |

| Spindle torque ( Nm) | 143 | 249 | 307 |

| Tool holder type | BT50 | BT50 | BT50 |

| Pull stud | BT50-45° | BT50-45° | BT50-45° |

| ATC capacity hold | 24 (manipulator) | 24 (manipulator) | 24 (manipulator) |

| Tool change time ( s ) | 3.5 (knife to knife) | 3.5 (knife to knife) | 3.5 (knife to knife) |

| Max tool weight (kg) | 25 | 25 | 25 |

| Max diameter of tool (mm) | Φ110/Φ220 | Φ110/Φ220 | Φ110/Φ220 |

| Air pressure (MPa) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Machine weight (kg) | 10500 | 12500 | 13500 |

| Machine overall size ( L x W x H ) mm | 3800x 3000x 3020 | 4300x 3150x 3800 | 4300x 3150x 3900 |

Resources & Downloads:

HC Series Horizontal Machining Center Product Introduction :

Product Features:

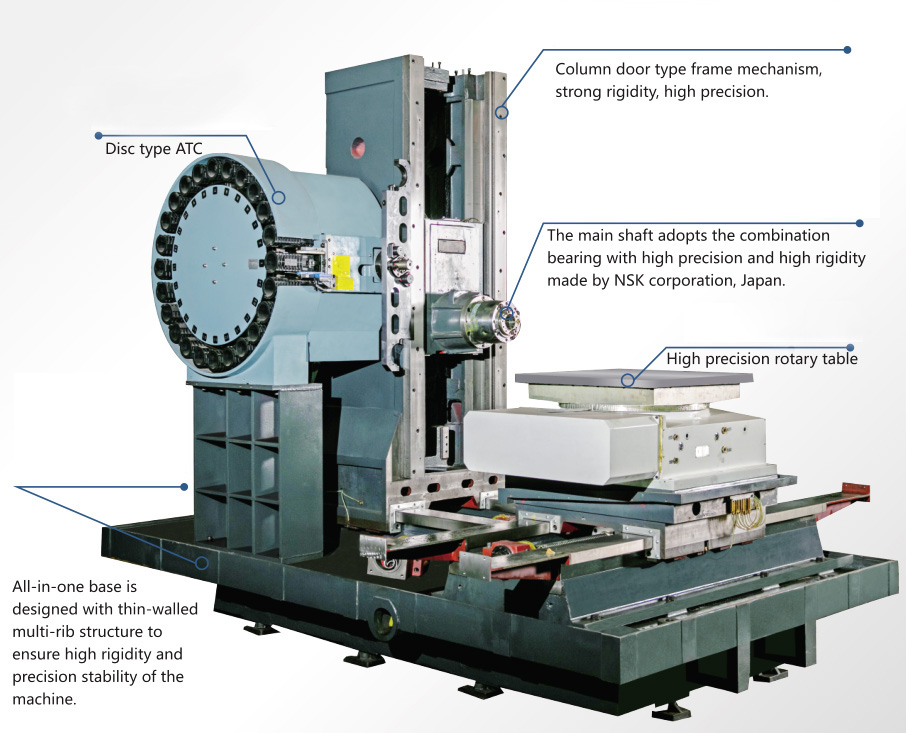

HC series The base, column, slide, and headstock of this machine tool are made of high-quality cast iron HT300.

The design of dense bars in the large foundation section is adopted, and finite element analysis is adopted to ensure high bending and torsional rigidity, so that it has a high natural frequency and improved vibration resistance.

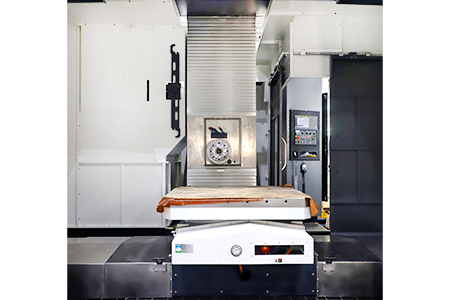

The triaxial hard rail (quenching) meets the technical performance requirements. Large amount of knife and high precision requirements. After secondary aging treatment, internal stress is eliminated. It has the characteristics of good overall rigidity, good vibration absorption and seismic performance.

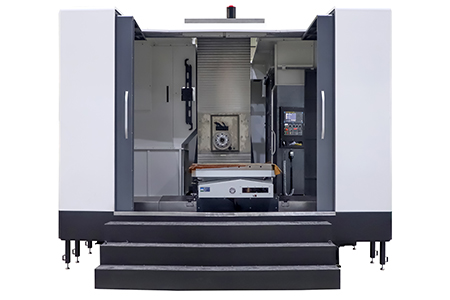

It is widely used in the processing of box parts, shell parts, and disc-shaped parts in the military, automobile, mold, and machinery manufacturing industries. After a single clamping, the parts can be processed in multiple processes such as milling, boring, drilling, expanding, reaming, tapping, etc., with high precision, high automation, high reliability, high degree of mechanical and electrical integration, simple operation, beautiful overall appearance .

Product Description

HC series horizontal machining center is Ants machine on the basis of absorbing domestic and international advanced machine design concept to design and development of horizontal machining center, this machine adopts large span guideway design, machine tool rigidity on the whole, carryjing capacity is strong, with a CNC rotary table, suit for body parts, machine tool base, pllar and other polyhedron for processing, a dlamping can finish milling, boring, drilig, tapping and other processes more than rough and finish machining.

The machine can choose FANUC and Siemens system, rotary table, ATC, spindle, rail, screw are Taiwan brands.

| Number | Standard Equipment | Number | Optional Equipment |

| 1 | 24 tool ATC | 1 | 32 Arm chian type ATC |

| 2 | Spindle air curtain dust control system | 2 | 40 Arm chian type ATC |

| 3 | Workpiece cooling system | 3 | Central outlet of spindle (equipped with high pressure cooling device) |

| 4 | Equal division CNC rotary table | 4 | ZF gearbox drive |

| 5 | Automatic lubrication system | 5 | Spindle oil cooling device |

| 6 | Spiral chip removal device | 6 | Arbitrary indexing CNC rotary table |

| 7 | Chain-plate type chip lifter | 7 | Scraper lift chip remover |

| 8 | Integral shield | 8 | 3 axis linear scale |

| 9 | The toolkit | 9 | Tool detection device |

| 10 | Anchor bolt and pad iron | 10 | Workpiece detection device |

| 11 | Door opening protection (door protection) | ||

| 12 | Portable chip air gun | ||

| 13 | Machine cleaning water tank | ||

| 14 | Simple oil and water separator |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life