Sawing machine

Milling Machine

Grinding Machine

Lathe Machine

Drilling machine

EDM/WEDM Machine

Laser Cutting Machine

Slotting Shaping Machine

Metal Forming Equipment

Tubes and Profile Processing

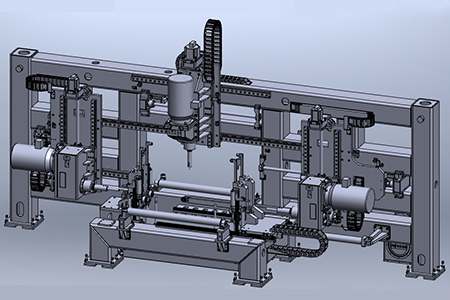

HD700-3D/HD1000-3D/HD1250-3D High Speed 3D CNC Beams Drilling Line

Max. workpiece thickness : 80mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | HD700-3D | HD1000-3D | HD1250-3D | |||||

| Work-piece parameter | H Beam | Web H (mm) | 150~700 | 150~1000 | 150~1250 | |||

| Flange B (mm) | 75~400 | 75~500 | 75~600 | |||||

| U Beam | Web H (mm) | 150~700 | 150~1000 | 150~1250 | ||||

| Flange B (mm) | 75~200 | 75~250 | 75~300 | |||||

| Max. Work-piece thickness (mm) | 80 | |||||||

| Max. Feeding length (mm) | 12000 or 15000 (optional) | |||||||

| Main spindle | Qty. | 3 | ||||||

| Spindle taper | BT40 | |||||||

| Spindle rotation speed (r/min) | 200~3000 | |||||||

| Feeding speed (mm/min) | 0~5000 | |||||||

| Max. hole diameter (mm) | φ40 | |||||||

| Center

line movement scope (mm) |

Center slide table/

Horizontal direction |

45~650 | 45~950 | 45~1200 | ||||

| Fixed side/movement side

Vertical direction |

30~370 | 30~470 | 30~570 | |||||

| Tool Magazine(optional) | Qty. | 3 | ||||||

| Number of tools in tool magazine | 3×4 | |||||||

| Marking function

(optional) |

Character number | 36 | ||||||

| Character size (mm) | Φ10 | |||||||

| Electrical system | CNC system | FAGOR 8070 or SIEMENS | ||||||

| CNC axis number | 7+3 | |||||||

| Cooling system | No. of nozzle | 3 | ||||||

| Pressure of compressed air (Mpa) | 1 | |||||||

| Cooling way | Spray cooling, internal cooling & external cooling | |||||||

| Hydraulic system | Hydraulic pump pressure (Mpa) | 15 | ||||||

| Motor power (kW) | 5.5 | |||||||

| Overall dimension(L×W×H) (m) | About 4.85×2.1×3.5 | About 5.45×2.1×3.5 | About 6×2.1×3.5 | |||||

| Main Machine weight (Kg) | About 8000 | About 9000 | About 10000 | |||||

Applicable Industry:

This machine is mainly used for processing holes on H-beam, channel beam with high speed. It adopts spindle servo motor, controls by CNC system, and in-feeding by CNC carriage, high efficiency, and high precision; and it is wildly used in construction, bridge and other industries.

Product Feature:

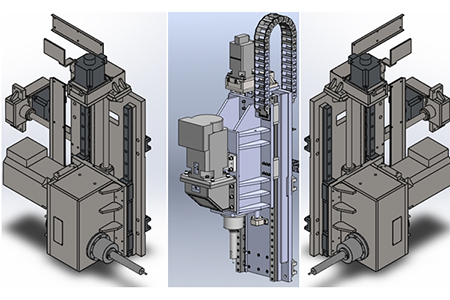

1.The drilling machine is mainly composed of machine bed, CNC sliders (3), drilling spindle boxes (3), clamping device, detecting device, cooling system, iron chip box, etc.

2. The machine body is welded by square steel pipe, the machine body structure has been strengthened in the place where the force is high, the welding is completed and the artificial aging treatment was carried out.

3. The spindle adopts high precision spindle BT40, which has high rotary precision and good rigidity. Can use twist drill and carbide drill, a wide range of applications.

4. The work-piece is fixed by hydraulic clamping. There are five hydraulic cylinders, which are clamped horizontally and vertically respectively.

5. The machine is adopted by carriage feed, the feed carriage is driven by the servo motor through the gear rack after decelerating by the reducer, and is equipped with a laser alignment device on the machine body.

6. Cooling system: air mist cooling, with the effect of internal cooling and external cooling..

7. Chip collection box: universal casters guide, simple and convenient moving.

8. This machine tool should be equipped with Korean YESTOOL brand taper shanks and cutters, which are provided by customers.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.