Sawing machine

Milling Machine

Grinding Machine

Lathe Machine

Drilling machine

EDM/WEDM Machine

Laser Cutting Machine

Slotting Shaping Machine

Metal Forming Equipment

HD2016S High Speed CNC Drilling Machine

Warranty : 1 Year for machinery warranty

Availability : On Stock

WhatsApp : +86-19534031668

Wechat : +86-19534031668

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | HD2016S |

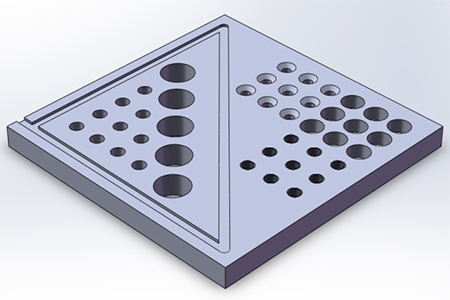

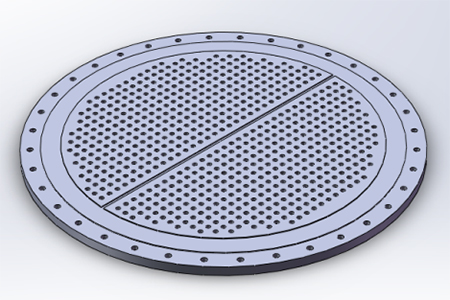

| Max work piece size (L×W) | 2000x1600mm plate or Φ1600mm flange |

| Thickness of work piece | 6–100mm |

| Drill unit type | sliding table, servo control |

| Drill head quantity | One |

| Spindle motor power | 15 kW |

| Max drill diameter | Φ40mm |

| Taper hole of spindle | BT50 |

| Spindle speed | 30~3000r/min |

| Spindle vertical stoke (Z axis) | 300mm |

| Servo motor power of X axis | 2.0 kW |

| Servo motor power of Y axis | 1. 5 kW |

| Servo motor power of Z axis | 2.0 kW |

| Motor power of scrap cleaner | 0.75 kW |

| Clamping type | 12 Hydraulic clams |

| Electric control type | SIEMENS PLC |

| CNC axis quantity | 3 |

| Position precision | ±0.1mm |

| Total motor power | 30kW |

| With function of CAD/CAM automatic generation | |

| With function of break point memory (Restart production easily after power off) | |

| Overall size | About 4500x3900x3200mm |

| Weight | About 9000 |

Applicable Industry:

Mainly used for drilling tube plate, clapboard, flange and large plate in petrochemical, boiler, wind power, flange industries and also for connection plates in building, bridge, heat exchange, iron tower industries.

Product feature:

1. Heavy-load linear roller guide pairs are equipped on two sides of the machine bed respectively. The longitudinal movement of the gantry’s two sides is driven synchronously via AC servo motor and precise ball screw pair of big pitch.

2. Two movable slides are equipped on the cross beam of gantry. The sliders are guided by two linear roller guide pairs and driven by AC servo motor and precise ball screw pair of big pitch respectively.

3. The slides on the cross beam are equipped with vertical CNC feeding ram-type drilling spindle, which adopts special conversion motor with heavy load for spindle. The motor drives the spindle via synchronous belt. The drilling spindle adopts Taiwan precision spindle (inner-cooling) with disk spring automatic broach mechanism, hydraulic cylinder loosing cutter, very convenient to change shank.

4. The machine is equipped with hydraulic system to finish the hydraulic balance of vertical ram and hydraulic cutter loosing of spindle.

5. It adopts SIEMENS CNC system, equipped with RS232 interface and LCD screen. The automatic programming provided can not only generate processing programs automatically, but also preview hole position before drilling.

6.It is equipped with chain-plate type automatic chip-conveyor and chip collection trolley. The cooling system is equipped with paper filer, high-pressure inner-cooling pump and low-pressure outer-cooling pump, which are used for inner-cooling or outer-cooling of cutter.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.