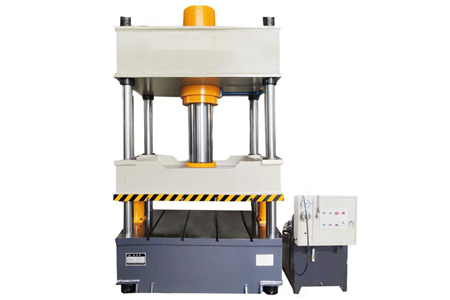

HP32 Series Four Column Hydraulic Press

Nominal Pressure : 63~500T

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Description | Unit | HP32-63T | HP32-100T | HP32-160T | HP32-315T | HP32-500T | |

| Nominal Pressure | KN | 630 | 1000 | 1600 | 3150 | 5000 | |

| Liquid Max. Working Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | |

| Oil cylinder range | mm | 260 | 300 | 300 | 700 | 900 | |

| Largest open | mm | 500 | 600 | 480 | 1200 | 1500 | |

| Effective area of the workbench | Left & Right | mm | 520 | 640 | 700 | 1260 | 1400 |

| Front & Back | mm | 520 | 550 | 700 | 1160 | 1400 | |

| Bench height | mm | 580 | 700 | 680 | 765 | 730 | |

| Covers area | mm | 1700*900 | 1900*850 | 2000*1000 | 3000*1600 | 4000*1900 | |

| Machine height | mm | 1850 | 2300 | 2560 | 4200 | 4800 | |

| Fast forward speed | mm/s | 26 | 80 | 226 | 150 | 120 | |

| Working speed | mm/s | 15-20 | 10-17 | 12-18 | 8-13 | 12-16 | |

| Return rate | mm/s | 57 | 64 | 64 | 68 | 71 | |

| Motor | KW | 5.5 | 5.5 | 7.5 | 15 | 15*2 | |

| Ejection Cylinder Pressure | KN | / | 200 | 400 | 630 | 1000 | |

| Ejection Cylinder Stroke | mm | / | 200 | 200 | 300 | 300 | |

Resources & Downloads:

HP32 Series Four Column Hydraulic Press Product Introduction :

Introduction:

HP32 series hydraulic press machine is suitable for the pressing process of metal materials, such as: metal stamping bending, flanging, thin plate stretching and pressing, correction, cold extrusion of metal parts, etc. It can also realize the pressing process of plastic products and powder products. It is suitable for various stamping processes such as stretching, punching (blanking device should be selected), bending, flanging, cold extrusion, etc. of metal materials. It is also suitable for straightening, pressing and forming of powder products and abrasive products, and plastic products, compression molding of insulating materials.

1. High machine precision: This HP32 series hydraulic press adopts a four-column three-plate structure. The vertical precision of the movable plate is controlled by four precision guide sleeves. The parallel precision of any point between the lower working surface and the upper working surface is within 0.03MM.

2. The height and the size of the working area can also be customized according to customer needs.

3. Accurate positioning by pressing down: Adjustable mechanical positioning of oil cylinder (accuracy 0.05mm), position ruler electric positioning (accuracy 0.03mm), pressure sensor pressure positioning (accuracy 0.1kgf).

4. Imported accessories: The hydraulic and electrical components of the 100-ton three-beam four-column hydraulic press are made in Japan, Taiwan, and France. The failure rate is very small, the efficiency is high, the noise is low, and the maintenance is convenient.

5. High safety factor: The safety design is comprehensive, the flat button is started by both hands, and the machine can be started by jogging at the same time within 0.5 seconds. The front of the 100-ton three-beam four-column hydraulic press workbench is equipped with a safety grating. If the machine is in operation, if the hand is accidentally inserted into the work space, the machine will automatically rise, and the red light will light up when the grating fails, with a high safety factor.

6. Convenient mold adjustment: HP32 series hydraulic press is equipped with up and down inching buttons, which is convenient for mold installation and calibration.

7. The system is easy to adjust: the pressure is adjusted by the overflow valve, the speed is adjusted by the speed control valve, and the stroke is adjusted by the proximity sensor and the falling time. Decline pressure holding time, output record and count.

8. Energy saving: Since the hydraulic cylinder adopts a fast combination cylinder, the motor only needs 2.2 kilowatts of power: the motor stops automatically after 10 minutes of operation, so as to prevent unnecessary additional power consumption caused by not operating the machine.

9. Only need to restart the motor when working.

10. High production efficiency: HP32 series hydraulic press adopts a master cylinder, which can realize rapid rise and stable pressurization of the hydraulic press, and improve production efficiency.

11. Low noise: the noise does not exceed 60 decibels when the device is in standby.

12. Easy to move the machine: HP32 series hydraulic machine is equipped with four casters under the machine, which can be moved lightly, labor-saving and efficient.

13. Easy to return and clean up: the working surface is equipped with a blanking chute and blowing device.

14. It is convenient to move the machine: there are casters and foot cups under the workbench, which can be moved lightly, labor-saving and efficient.

Features:

1.Computer optimized structure design, three-beam four-post structure, simple, economical and practical.

2.Hydraulic control cartridge valve integrated system reliability, long life and small hydraulic impact, reducing the link pipe and leak points.

3.Independent electrical control system working reliably. Action and intuitive. Easy maintenance.

4.Use the button centralized control, with adjustment for manual and semiautomatic operation.

5.Via the operator panel to choose from. Can be achieved given away two constant pressure forming process, and has features such as security during rolling.

6.Slider working pressure load and slow down quickly work into the travel range can be adjusted according to process requirements.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life