YQ32-315T Three-beam Four-column Hydraulic Press Machine

Maximum liquid pressure:25Mpa

Slider stroke:800mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Description | YQ32-315T |

| Nominal Force | 3150 KN |

| Rejection force | 630 KN |

| Maximum liquid pressure (Mpa) | 25 |

| Maximum opening height (mm) | 1250 |

| Table size (mm) | 1260X1200 |

| Table height (mm) | 850 |

| Down speed of empty range (mm/s) | 120 |

| Working speed (mm/s) | 5-12 |

| Return speed (mm/s) | 100 |

| Servo Motor power (kw) | 17 |

| Oil pump displacement (ml/R) | 80 |

| Jacking force (t) | 63 |

| Slider stroke (mm) | 800 |

| Ejection stroke (mm) | 250 |

| Return force (t) | 30 |

| Approximate weight (t) | 11 |

| Length (mm) | Machine: 1720mm

Pumping station:1100mm |

| Width (mm) | Machine: 1500mm

Pumping station:1200mm |

| Height (mm) | Machine: 4300mm

Pumping station:1700mm |

Resources & Downloads:

YQ32-315T Three-beam Four-column Hydraulic Press Machine Product Introduction :

Main application: This three-beam four-column Hydraulic Press Machine Model number is YQ32-315T which is 315 ton press force. The hydraulic press machine mainly used for a series of molding products such as metal material punching, stretching, automobile parts, powder products molding, glass fiber reinforced plastic products molding and so on.

Process action: Slide: fast down – slow down pressurization – holding pressure delay – unloading pressure delay – return. Can be customized according to customer requirements

Machine features:

1.The control system of this machine is equipped with manual and semi-automatic working modes.

2.the hydraulic system adopts two-way cartridge valve integrated system, and the electrical system adopts PLC (11-inch) programmable controller

3.The machine is equipped with servo motor with pressure sensor, pulling line ruler.

4.The power system of this machine is installed on the ground for easy maintenance and repair.

5.The machine is equipped with independent removable control cabinet for easy operation.

6.This machine can limit pressure, limit range, positioning, process action.

Shanghai ANTS Machine Company is a company focusing on the research and development, production and service of large and medium-sized forging and hydraulic press machine, with an annual output value of nearly 200 million yuan and a plant area of more than 30,000 square meters, the main products include three-beam and four-column hydraulic press machines, four-beam and four-column hydraulic press machines, single-column hydraulic press machines, gantry hydraulic press machines, frame-type hydraulic press machines, powder molding hydraulic press machines, metal stretching hydraulic press machines, glass fiber reinforced plastic molding hydraulic press machines, composite material forming hydraulic press machines, forging hydraulic press machines, hydraulic press machines, press fitting and straightening machine and all kinds of supporting molds (punching, drawing, molding, forging), etc.

Main Parts

| NO | Name | Brand/Origin |

| 1 | Valve | Taifengln/Senteke/Lianheng |

| 2 | Seals | Taiwan Dingzing/Tongyong, China |

| 3 | Core Electrical Appliances | Schneider |

| 4 | Intermediate relays | Schneider or Siemens |

| 5 | Motors | PHASE, Italy |

| 6 | Column | ANTISHICNC |

| 7 | Cylinders | ANTISHICNC |

| 8 | Electric control | ANTISHICNC |

Optional Parts

| Protective grids | Quick mold change system |

|

|

| Moving working table | Water cooling system |

|

|

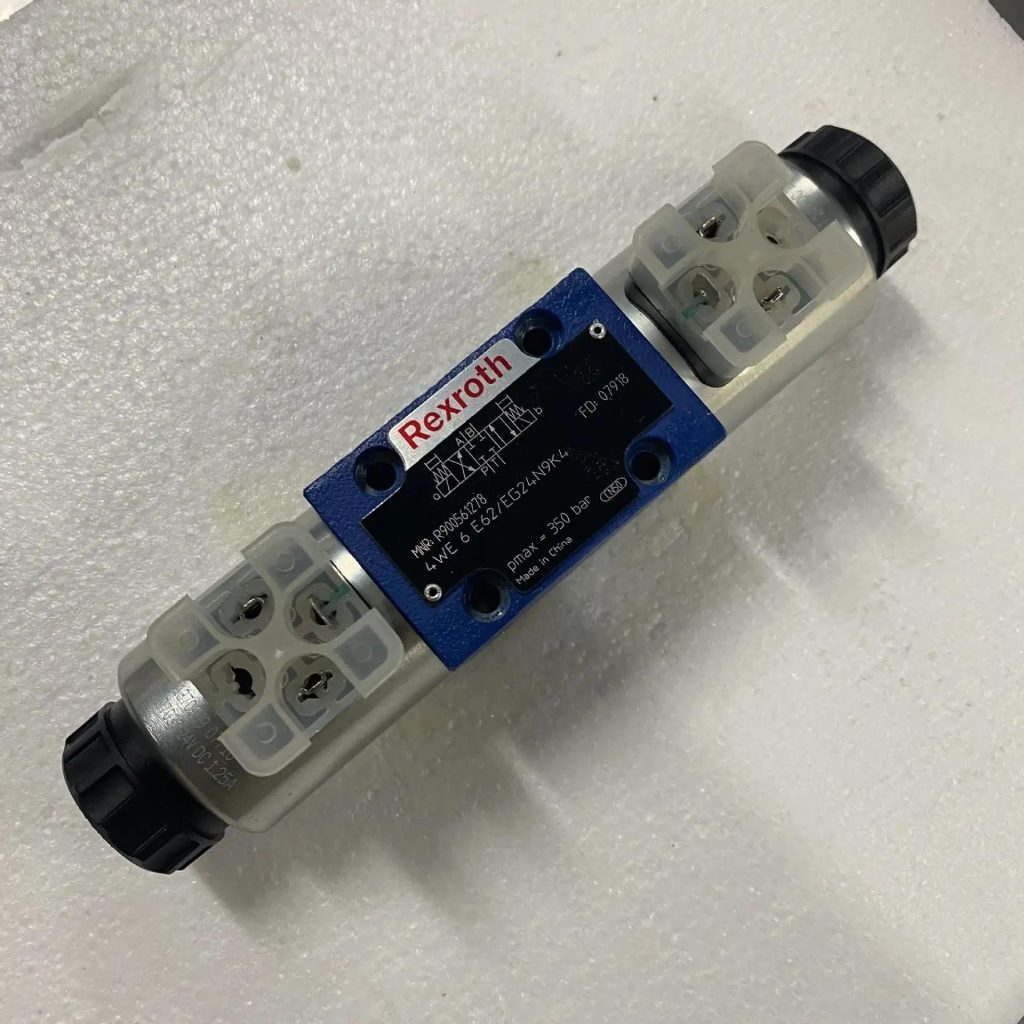

| Light curtain protection | Rexroth valves |

|

|

| (CNC) Mold clamping accessories | (Manual) Mold clamping accessories |

|

|

| Safety support device | |

|

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life