M11100 M1000 M11200 Large Grinding Wheel Precision Centreless Grinding Machine

Grinding diameter : 10-200mm

Grinding length : 590mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Technical Data | M11100 | M10200 | M11200 |

| Plunge feeding Grinding diameter(mm) | 10~100 | 10~200 | 10~200 |

| Plunge feeding Grinding length (mm) | 390 | 390 | 590 |

| Through feeding Grinding diameter (mm) | 10~100 | 10~200 | 10~200 |

| Grinding Wheel Spec. (mm) | 500*400*305 | 600*400*305 | 500*600*305 |

| Regulating Wheel Spec. (mm) | 350*400*203 | 350*400*203 | 350*600*203 |

| Grinding Wheel Speed (r/min) | 1330 | 1110 | 1330 |

| Regulating wheel speed (r/min) | 10~200 | 10~200 | 10~200 |

| Swiveling Angle of Regulating Wheel | |||

| Vertical (degree) | -2°~4° | -2°~4° | -2°~4° |

| Horizontal(degree) | -2°~4° | -2°~4° | 0°~ 3° |

| Micro Feed/Division (mm) | 0.002 | 0.002 | 0.002 |

| Feed/Division (mm) | 0.01 | 0.01 | 0.01 |

| Dresser Feed Amount/Division (mm) | 0.01 | 0.01 | 0.01 |

| Height from center of GW & RW to worktable (mm) | 290 | 290 | 290 |

| Motor Power | |||

| Grinding wheel motor (KW) | 22 | 30 | 37 |

| Grinding wheel motor (KW) | 2.2 | 2.2 | 3 |

| Power supply | 3N 50HZ 380V | 3N 50HZ 380V | 3N 50HZ 380V |

| Dimension(L*W*H) (mm) | 3500*1850*1720 | 3600*1850*1720 | 3500*1850*1720 |

| Machine weight (kg) | ≈10000 kg | ≈10000 kg | ≈10000 kg |

| Accuracy(Standard bars) | |||

| Roundness (mm) | 0.002 | 0.002 | 0.002 |

| Cylindricity (mm) | 0.005 | 0.005 | 0.005 |

| Roughness (μm) | Ra0.32 | Ra0.32 | Ra0.32 |

Resources & Downloads:

M11100 M1000 M11200 Large Grinding Wheel Precision Centreless Grinding Machine Product Introduction :

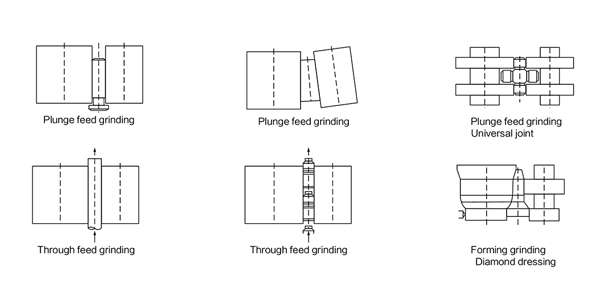

Through feed:Grinding of various cylindrical parts,ring parts and long bars.

Plunge-in : Grinding of cones with a cone less than 1:20 and various shaped rotating parts

Product Application Areas: Bearing, Auto parts, Construction Machinery, Other related field.

CNC System & Software : SIEMENS, FANUC, MITSUBISHI

Machine Tool Main Features

◆ Bed body

Normalization heat treatment and natural aging treatment of high-quality castings are adopted to stabilize the internal structure and ensure firmness, wear resistance and small deformation during use.

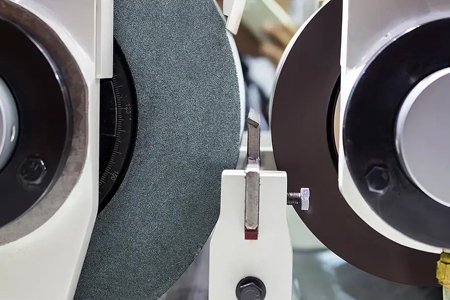

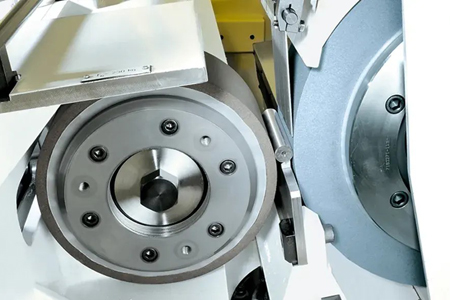

◆ Grinding wheel and guide wheel device

1. The machine tool adopts the layout of fixed grinding wheel frame and movable guide wheel frame.

2. The grinding wheel is cantilever structure, and the spindle of the grinding wheel adopts multi-piece long bearing hydrodynamic oil film bearing.

3. The guide wheel is cantilever structure, and the main shaft of the guide wheel adopts integral 1:30 cone sliding bearing.

◆ Feed device

The main feed slide adopts needle roller guide rail, which is sensitive in movement, high in feed accuracy and long in service life.

◆ Dressing device

The grinding wheel and guide wheel dresser adopt hydraulic transmission and stepless speed regulation.

◆ Electrical control device

The speed regulation of guide wheel adopts AC variable frequency stepless speed regulation.

Operation Applications

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life