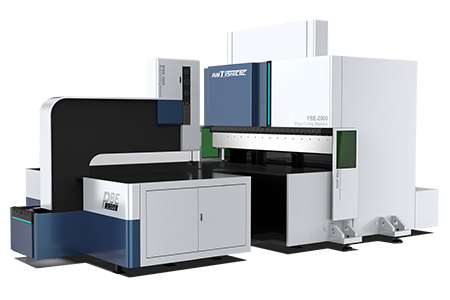

PBEH SERIES Heavy Duty CNC PANEL BENDER

Max. Bending Length: 1400-3000mm

Max. Sheet Width: 1400-1250mm

Max. Bending Height: 170mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Name | Unit | PBEH-1400 | PBEH-2000 | PBEH-2500 | PBEH-3000 | |

| Max. Bending Length | mm | 1400 | 2000 | 2500 | 3000 | |

| Max. Sheet Width | mm | 1400 | 1250 | 1250 | 1250 | |

| Max. Bending Height | mm | 170 | 170 | 170 | 170 | |

| Min. Workpiece Size (four sides bending) | mm | 170 | 200 | 200 | 200 | |

| Min. Workpiece Size (single side bending) | mm | 170 | 170 | 170 | 170 | |

| Bending Angle | ° | ±180 | ±180 | ±180 | ±180 | |

| Max. Pressing Force

(Heavy duty) |

T | 38 | 53 | 80(3 AXES) | 155(3 AXES) | |

| Min. Sheet Thickness | mm | 0.35 | 0.35 | 0.35 | 0.35 | |

| Power(Heavy duty) | KW | 44 | 49 | 70 | 100 | |

|

Max. Sheet Thickness

|

SS | mm | 1.5 | 1.5 | 1.5 | 1.5 |

| MS | mm | 2.0 | 2.0 | 2.0 | 2.0 | |

| AL | mm | 3.0 | 3.0 | 3.0 | 3.0 | |

| Dimensions(L×W×H) | mm | 2350x4600x2700 | 3100x5700x2700 | 3580x5700x2700 | 3100x5700x2700 | |

| Working Voltage | V | 380V±10% | 380V±10% | 380V±10% | 380V±10% | |

Resources & Downloads:

PBEH SERIES Heavy Duty CNC PANEL BENDER Product Introduction :

PBEH Series

PBEH series are fully automatic heavy-duty CNC bending centers, adopting servo motors as the main power source to precisely control the output; the machine body is welded with steel plate and then tempered as a whole, clamped at once, and precision machined by imported numerical control equipments to ensure the rigidity of the machine body and the machining accuracy; it is equipped with a new generation of high-end numerical control system; it is highly efficient and energy-saving. The machine body is welded and tempered as a whole with steel plate, and precision processing by imported CNC equipment ensures the rigidity of the machine body and processing accuracy.

Main Components Configuration

| NO. | Item | Brand |

| 1 | Controlling System | SYNTEC/NLKER |

| 2 | Servo Driver | SYNTEC/WISTRON |

| 3 | Servo Motor | SYNTEC/WISTRON |

| 4 | Motor Reducer | NEWSTART/SHAMPO |

| 5 | Ball Screw | HIWIN/NGY |

| 6 | Bearing | NACHI/NSK |

| 7 | Linear Guide | HIWIN/NGY |

| 8 | Coupling | MIKIPULLEY |

| 9 | Lubrication System | BAOTN |

| 10 | Electric Component | Schneider |

| 11 | Pneumatic Component | Airtac/JULY |

Function Configuration

| Name | Configuration |

| Feeding Type | Arm Hold Dual Rotate |

| Table Type | Brush |

| Speed Adjustment | Standard |

| Senior Command | Standard |

| Arc Command | Standard |

| HEM Command | Standard |

| Robot Connection | Standard |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life