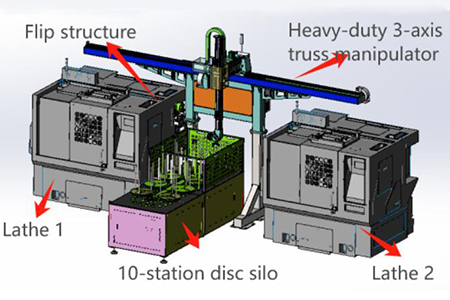

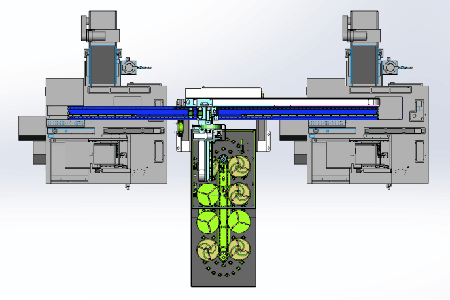

TCK50A & TCK50Y Duplex CNC Lathe with Truss Automatic Production Line

Max. Swing over bed: Φ560mm

Swing over cross slide: Φ260mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | TCK50Ax500 |

| Max. Swing over bed | mm | Φ560 |

| Swing over cross slide | mm | Φ260 |

| Distance between center | mm | 500 |

| Max. disc machining diameter | mm | Φ440 |

| Standard chuck specifications | Inch | 8 inches |

| X-axis maximum travel | mm | 240 |

| Z-axis maximum travel | mm | 540 |

| Spindle maximum speed | rpm | 3000rpm |

| Spindle speed change | Infinitely variable speed | |

| Spindle end code | A2-6 | |

| Spindle through hole | mm | Φ66 |

| Draw tube through hole | mm | Φ55 |

| Rapid traverse speed | m/min | X:18 Z:18 |

| cutting feed rate | mm/min | 1-15000 |

| X/Z direction motor torque | NM | 10/10 (X direction with brake) |

| Spindle motor power | KW | 11 |

| Horizontal turret station | 8 | |

| Turning tool body size | mm | 25´25 |

| Maximum boring tool diameter | mm | 40 |

| Sleeve diameter | mm | 70 |

| Sleeve stroke | mm | 80 |

| Tailstock sleeve tapered hole | Mohs 5# | |

| Maximum travel of tailstock | mm | 450 |

| Total power capacity | KVA | 18 |

| Cutting water tank capacity | L | 90 |

| Overall dimensions (length × width × height) | mm | 2700*2000*2000 |

| Total Weight | KG | 3600 |

| Specifications | Units | TCK50Yx400 |

| Max. Swing over bed | mm | Φ560 |

| Swing over cross slide | mm | Φ260 |

| Distance between center | mm | 400 |

| Max. disc machining diameter | mm | Φ350 |

| Standard chuck specifications | Inch | 8寸 |

| X-axis maximum travel | mm | 260 |

| Z-axis maximum travel | mm | 540 |

| Spindle maximum speed | rpm | 3000rpm |

| Spindle speed change | Infinitely variable speed | |

| Spindle end code | A2-6 | |

| Spindle through hole | mm | Φ66 |

| Draw tube through hole | mm | Φ50 |

| Rapid traverse speed | m/min | X:18 Z:18 |

| cutting feed rate | mm/min | 1-15000 |

| X/Z direction motor torque | NM | 15/15 (X direction with brake) |

| Spindle motor power | KW | 11 |

| Powered Turret Specifications | TCSDY-80-12 | |

| Turret tool holder | BMT45 | |

| Y axis travel | -45+45 | |

| Powered tool turret chuck | mm | (ER20) |

| Turning tool body size | mm | 25´25 |

| Maximum boring tool diameter | mm | Æ32 |

| Sleeve diameter | mm | 70 |

| Sleeve stroke | mm | 80 |

| Tailstock sleeve tapered hole | Mohs 5# | |

| Maximum travel of tailstock | mm | 450 |

| Total power capacity | KVA | 22 |

| Cutting water tank capacity | L | 90 |

| Overall dimensions (length × width × height) | mm | 2600*1850*2100 |

| Total Weight | KG | 3200 |

Resources & Downloads:

TCK50A & TCK50Y Duplex CNC Lathe with Truss Automatic Production Line Product Introduction :

Product Introduction

1. It has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.

2.It adopts a 30° overall inclined bed structure and is equipped with high-precision preloaded Taiwan linear roller guides. The machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining.

3.The spindle adopts a high-precision spindle bearing set and has been precision assembled and dynamically balanced tested to ensure high spindle accuracy, low noise and strong rigidity.

4.Use the tool turret method to achieve fast tool changing and high positioning accuracy.

5 The X and Z direction feeds use servo motors directly connected to the screw through high-torque and low-inertia elastic couplings to ensure positioning accuracy and repeatable positioning accuracy.

6.Adopt advanced centralized automatic lubrication device, regular and quantitative automatic intermittent lubrication, and work stably and reliably.

7.Use domestic hydraulic chuck.

8.The hydraulic tailstock is manually adjusted and locked, and the hydraulic piston is pressed against the workpiece for processing.

Standard Equipment&Optional Equipment

| Name | Model | Quantity | Brand |

| CNC lathe | TCK50A/TCK50Y | 2 units | ANTISHICNC |

| Truss robot | DZ1-2-5550 | 1 set | Dongzhi |

| flip mechanism | ZD-HRO70L2-MHL32D | 1 set | Dongzhi |

| Tray silo | DZ-P10

φ50-φ220 |

1 set | Dongzhi |

| Jaws | DZ-HRO70-CY63 | 1 set | Dongzhi |

| Packing and shipping | 1 set | ||

| Installation and commissioning customer training | 1 set |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life