AHF Series Premium High-end Fast Cutting Wire Cut WEDM Machine

Max cutting thickness : 500 mm

Max load capacity : 450 kg

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| ITEM of Description | AHF35 | AHF45 |

| Work surface size (mm) | 360×630 | 570×810 |

| Work surface travel (mm) | 350×450 | 450×550 |

| Maximum cutting thickness (mm) | 500 | 500 |

| Maximum load capacity (kg) | 300 | 450 |

| Manufacturing Standards | GB7926—2005 | GB7926—2005 |

| Wire cutting mode | Fast speed wire cut | Fast speed wire cut |

| Maximum cutting speed (mm²/min) | 100 | 100 |

| Processing area roughness Ra(um) | 2.5 | 2.5 |

| Maximum current (A) | 6 | 6 |

| Electrode wire diameter (mm) | 0.18 | 0.18 |

| Electrode wire fixed speed | 11M/S | 11M/S |

| Working fluid | DX-1 DX-4 | DX-1 DX-4 |

| Working fluid capacity (L) | 80 | 80 |

| Processing taper | 6°/80MM | 6°/80MM |

| Voltage | 380V/50HZ/3PH | 380V/50HZ/3PH |

| Control cabinet | AutoCut/HL | AutoCut/HL |

Resources & Downloads:

AHF Series Premium High-end Fast Cutting Wire Cut WEDM Machine Product Introduction :

Product Description

AHF Series high-end fast cutting wire cut machine tool adopts

AHF series high-end wire cutting machine is a kind of wire cut WEDM machine specially customized for high-end users by Shanghai ANTISHICNC according to the requirements of Japanese customers.

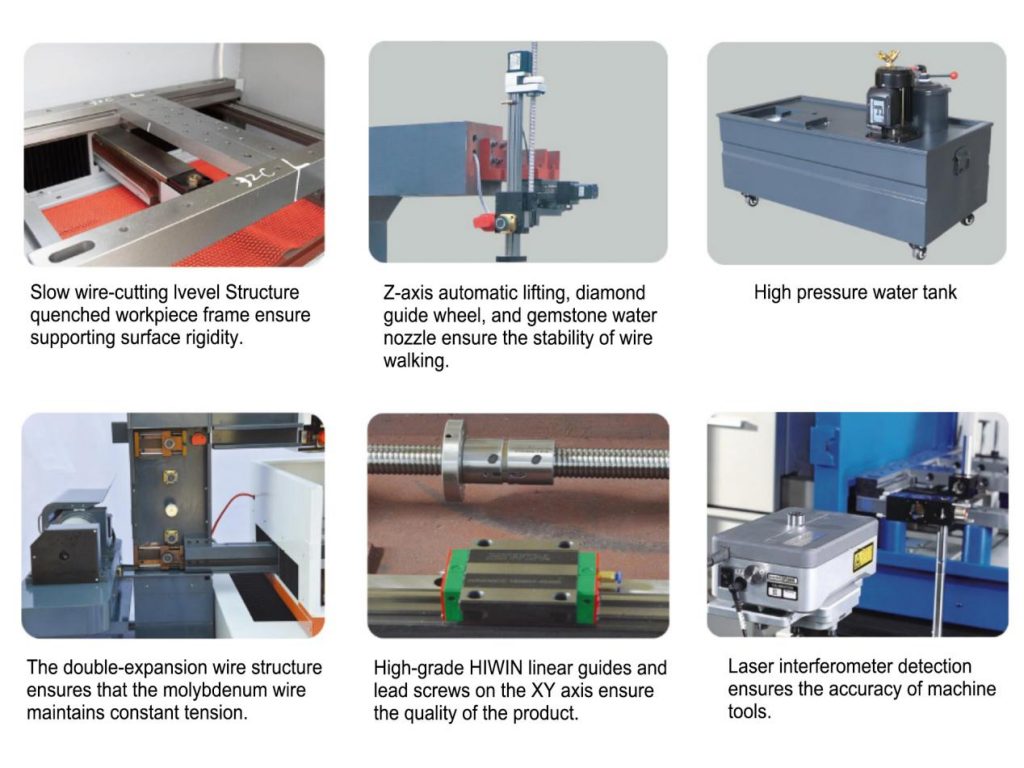

Fully take use of Taiwan orgional produced HIWIN linear guide and HIWIN ball screw

The machine tool has a novel structure, with a flat-shaped bed, C-shaped wire frame, and fully supported workbench.

Servo machine tools adopt Panasonic servo system

The main components adopt precision ball screws and steel guide rails, with high mechanical transmission precision. In particular, the taper machine tool has the characteristics of extremely strong rigidity.

The machine tool control part integrates computer, machine tool electrical, and pulse power supply. The microcomputer control system can be programmed and processed at the same time. The control system has automatic center finding, end shutdown, short-circuit rollback, power outage memory to resume processing, and graphic trajectory tracking display. , control functions such as placing and processing at any angle.

Application Fields

Processing objects: cutting forgings, forging dies and tooling cutting. Electrical discharge processing of various complex molds and parts, used for processing of various non-ferrous metals, tool steel, alloy steel and other materials.

Materials: Mainly include 45#, 5GrNIMo, 45Gr2NiMoSi, B2, H13 and other metal materials.

Standard Accessories

| NO | Accessories | Quantity |

| 1 | Bridge plate | 1 set |

| 2 | Spacer | 2 pieces |

| 3 | Fixture | 1 set |

| 4 | Calibrator | 1 piece |

| 5 | Foot Pad | 6 pieces |

| 6 | Wire tightener | 1 piece |

| 7 | Wire-travelling handle | 1 piece |

| 8 | Upright rocker | 1 piece |

| 9 | Taper waterproof shield | 1 piece |

| 10 | Water tank | 1 piece |

| 11 | Water pump | 1 piece |

| 12 | Plexiglas cover | 1 set |

| 13 | Machine cover | 1 piece |

| 14 | Power cable | 1 set |

| 15 | Water pipe | 3 sets |

| 16 | Wire protection Shield | 1 set |

| 17 | Hand-pressed oiler | 1 piece |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life