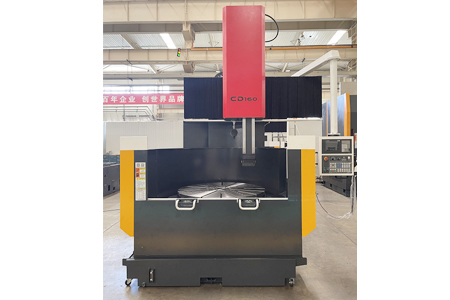

CD125/CD160 vertical CNC lathe

Max. swing dia. : Φ1250(49.212)

Max. turning dia. : Φ1100(43.307) mm(in)

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Description | Unit | Specification | |

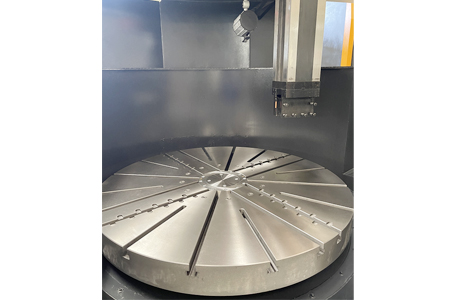

| Capacity | Dia. of table | mm (in) | 1000(39.370) |

| Max. swing dia. | mm(in) | Φ1250(49.212) | |

| Max. turning dia. | mm(in) | Φ1100(43.307) | |

| Max. work length | mm(in) | 900(35.433) | |

| Max. work weight | Kg(imb) | 4000(8820) | |

| Table | Rotation speed of table | r/min(rpm) | 15~150 |

| Max. torque of table | Nm(ft-lb) | 1500(1106) | |

| Power of main motor | kW(ph) | 15(20.4) (general motor) | |

| Feed | Travel X | mm(in) | 650(25.590) |

| Travel of slide sleeper Z | mm(in) | 900(35.433) | |

| Rapid traverse X/Z | mm/min() | 10(393.7)/10(393.7) | |

| Servo motor torque X/Z | Nm(ft-lb) | 23(16.961)/23(16.961) | |

| Servo motor power X/Z | kW(hp) | 4.0(5.44)/4.0(5.44) | |

| Ball screw diameter X/Z | mm | Φ50 /Φ50 | |

| Turret | Number of tools | 2 | |

| Tool section | mm | 32×32 | |

| Others | Power | kVA | 25 |

| Dimensions(L×W×H) | mm(in) | 2420(95.2)×2081(81.9)×3535(139.2) | |

| Gross weight | Kg(lmb) | 10000(22050) | |

Resources & Downloads:

CD125/CD160 vertical CNC lathe Product Introduction :

Introduction

CD125/CD160 vertical CNC lathe is a bigsize economical machine which is suitable for rough and finish machining plateand short shaft type parts. The machine base and column are symmetrical boxstructure. The guideways of crossbeam are treated by middle-frequency inductionand precision ground. Z-axis is box type structure which is suitable for biginner hole boring machining.

Product Features

1. The base, columns and beams are made of high-strength cast iron, which has good shock absorption; the large-span hardened guide rails are plastic-coated and scraped, with good wear resistance, small frictional resistance, and long-term precision retention.

2. Symmetrical box-type structure, high rigidity, capable of carrying large torque and heavy cutting.

3. The ram adopts a square structure with high rigidity, small deformation and good precision.

4. Fixed beam, good rigidity and high precision.

5. Single knife seat structure, good rigidity, stable and reliable precision.

6. The centralized machine tool operation panel makes the operation more convenient and faster.

7. Simple protection, low overall cost and high cost performance.

11. Intermediate frequency quenching and precision grinding, X-axis crossbeam sliding method has good dynamic response and long-lasting precision. The slideway is coated with a special material for the guide rail, which has low friction, wear resistance and quick response.

12.The Z-axis adopts a square ram structure with high rigidity. It has the advantages of processing large and deep holes.

13.All measurement units conform to the international measurement system.

14.The X/Z axis adopts high-precision ball screw and bearings, with long-lasting precision.

1) Electrical system: Standard configuration: KND2000T CNC system.

2) Spindle system:

lStandard configuration: 22KW servo main motor direct connection;

lOptional: 15KW servo main motor + self-made reducer.

3) Feed system:

lX/Z axis AC servo motor torque: 23NM/23NM;

lX/Z axis ball screw standard configuration: Hanjiang ball screw.

4) Tool: Shank size: 32 mm×32 mm (turning).

5) Machine tool protection:

lSimple protection, spacious operation space and convenient maintenance;

lMachine tool noise: in line with national standards <83db.

6) Lubrication system:

lAutomatic lubricating device, forcibly lubricating each guide rail and ball screw;

lThe oil filling time interval is adjustable, and the machine will display an alarm when the oil level is too low (lack of oil);

lThe lubricating oil is L-G68 guide rail lubricating oil;

7) Machine power supply:

lPower supply voltage range: AC three-phase 380V±10% 50Hz

l Power capacity: 25 kVA

8) Normal use conditions:

lAmbient temperature: 0~40℃

l Humidity: ≤85%

9) Machine tool color:

l Machine tool standard color;

lThe color of the machine tool can be changed according to the color palette provided by the user

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life