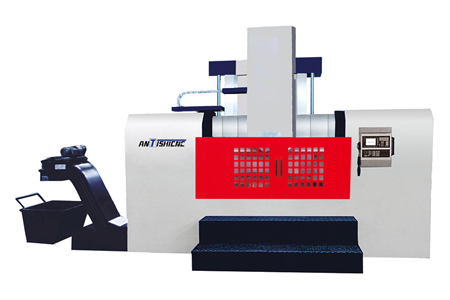

CK51-BD series double lead screw lifting heavy duty CNC vertical lathe

Max turning dia. : 2600mm

Max workpiece height : 1800mm

Max workpiece weight : 10t

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specification | Unit | CK5112BD | CK5116BD | CK5120BD | CK5123BD | CK5126BD |

| Maximum turning diameter | mm | 1250 | 1600 | 2000 | 2300 | 2600 |

| Table diameter | mm | 1000 | 1400 | 1800 | 2000 | 2300 |

| Maximum workpiece height | mm | 1000 | 1200/1400 | 1250/1400 | 1350/1600 | 1500/1800 |

| Maximum workpiece weight | t | 3.5 | 5 | 8 | 8 | 10 |

| WE Maximum Torque of table | KN.m | 25 | 30 | 40 | 40 | 45 |

| Working table speed range(4steps) | r/min | 1-250 | 1-160 | 1-100 | 1-80 | 1-40 |

| Maximum cutting force of vertical tool rest | KN | 18 | 22 | 22 | 22 | 22 |

| Feed range of vertical tool rest | mm/min | 0-500 | 0-500 | 0-500 | 0-500 | 0-500 |

| Horizontal travel of tool rest | mm | 700 | 915 | 1050 | 1180 | 1600 |

| Ram travel with vertical tool rest | mm | 650 | 800 | 800 | 800/1000 | 800/1000 |

| Fast moving speed of tool rest | mm/min | 2000 | 2000 | 2000 | 2000 | 2000 |

| Knife model | Square ram/electric knife table | |||||

| Beam speed | mm/min | 440 | 440 | 440 | 440 | 440 |

| Cross-sectional dimension of tool bar(W × H) | mm | 30×40 | 30×40 | 30×40 | 30×40 | 30×40 |

| Power of main motor | KW | 22 | 30 | 30 | 30 | 37 |

| Overall dimensions(L × W × H) | mm | 2277×2540×3415 | 2662×2800×3350 | 3210×2850×3910 | 3235×3240×3910 | 3380×3360×4000 |

| Weight of machine (Approx.) | t | 18 | 18.5/19.5 | 20/21.5 | 26/28 | 27/30 |

Resources & Downloads:

CK51-BD series double lead screw lifting heavy duty CNC vertical lathe Product Introduction :

1.CK51-BD series single column CNC heavy duty vertical lathe, using double screw improved beam, special column, bed, beam, frame design, so that the machine has high rigidity, high stability, high precision, to achieve strong cutting function. It is suitable for the machining of the inner and outer cylindrical surface, conical surface, cutting groove, thread and rotary surface of ferrous metal, non-ferrous metal and some non-metallic parts, such as hard alloy and ceramic cutting tools.

2. The column is a thermal symmetrical structure, and the seat ring is calculated by the computer with limited distance, and effective vibration isolation measures are taken, with high stiffness and vibration resistance.

3. The work table is thermally symmetrical, the main shaft is centered by double-row cylindrical roller bearings with high precision adjustable radial clearance, and the axial direction uses high-precision large thrust ball bearings as rolling guides. Therefore, the table has the characteristics of high rotation accuracy, large bearing capacity and small thermal deformation.

4. The surface of the guide rail is quenched with high frequency, and the hardness is HRC48-55 degrees.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life