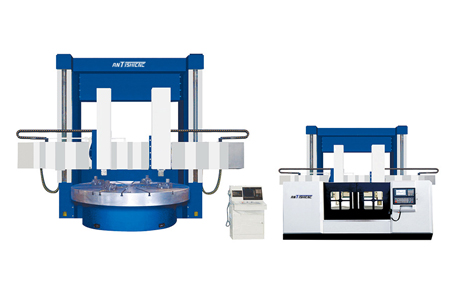

CK52 series double column numerical control vertical lathe

Max turning dia. : 8000mm

Max workpiece height : 4000mm

Max workpiece weight : 120t

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specification | Unit | CK5225 | CK5231 | CK5240 | CK5250 | CK5263 | CK5280 | CK5290 | CK52100 |

| Maximum turning diameter | mm | 2500 | 3150 | 4000 | 5000 | 6300 | 8000 | 9000 | 10000 |

| Table diameter | mm | 2250 | 2830 | 3200/3600 | 4500 | 4500/5700 | 7200 | 8000 | 8500 |

| Maximum workpiece height | mm | 1600/2000

Z2500 |

2000/2500 | 1600/2000

△150 |

2500/3150 | 3200 | 3150/4000 | 3150/4000 | 4000 |

| Maximum workpiece weight | t | 10/20 | 10/20 | 20/32 | 65 | 65/80 | 80/120 | 100/120 | 200 |

| Maximum Torque oftable | KN.m | 63 | 63 | 80 | 100 | 100 | 500 | 500 | 600 |

| Stage speed series | 4th gear stepless/16th gear | 4th gear stepless/16th gear | 4th gear stepless/16th gear | Fourth gear stepless/second gear stepless | Second gear stepless | Second gear stepless | Second gear stepless | Second gear stepless | |

| Working table speed range | r/min | 2-63 | 2-63 | 2-63 | 0.4-40 | 0.4-32 | 0.4-20 | 0.4-20 | 1-20 |

| Cutting force ofvertical tool rest | KN | 32 | 35 | 40 | 50 | L 50 R 70 |

L 80 R100 |

L 80 R 100 |

L 80 R 120 |

| Feedrangeofverticaltool rest | mm/min | stepless | stepless | stepless | 0.2-145 | 0.1-500 | 0.1-500 | 0.1-500 | stepless |

| Horizontal travel of tool rest | mm | -20-1400 | -20-1840 | -20-2150 | -20-2760 | -20-3415 | -20-4400 | -20-4700 | -50-5200 |

| Ram travel with vertical tool rest | mm | 1000/1250 | 1000/1250 | 1000/1250 | 1250/1600 | 1600/2000 | 1600/2000 | 1600/2000 | 2100 |

| Fast moving speedoftool rest | mm/min | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Cross-sectional dimensioii ofbolster | mm | 240×240 | 240×240 | 240×240

260×260 |

240×240

260×260 |

280×280

300×300 |

280×280

300×300 |

280×280

300×300 |

320×320 |

| Section size oftoolbar (Wxfi) | mm | 40×50 | 40×50 | 40×50 | 50×50 | 50×50 | 60×60 | 60×60 | 60×60 |

| Power of main motor | KW | 55 | 55 | 75 | 90 | 90 | 132 | 132 | 160 |

| Overall dimensions(L×W×H) | mm | 5400×4700×4800/5200 | 6050×4400×4930/5330 | 6900×5100×W5200/5700 | 10000×7000×7230/8530 | 12500×7500×9400/10700 | 14000×13000×9100 | 16000×13000×9100 | 16000×13000×10000 |

| Weight of machine(Approx.) | t | 32/34/38 | 36/40 | 48/50/52 | 81/84 | 120 | 180 | 200 | 400 |

Resources & Downloads:

CK52 series double column numerical control vertical lathe Product Introduction :

Product Features:

1. Vertical CNC lathe is a kind of excellent performance, a wide range of processes, high production efficiency, suitable for various industries of advanced processing equipment, can be used for internal and external cylindrical surface, internal and external cone and grooving, arc surface, various threads rough, finishing.

2. the main drive of the machine is driven by AC and DC motors, and the speed range of the table is realized by the AC 16-level spindle transmission mechanism and the DC two-stage gear transmission.

3. the table spindle using high-precision adjustable radial clearance double-row short cylindrical roller bearing centering, the table using constant static pressure guide, so that the table has high rotation accuracy, large bearing capacity, small thermal deformation and other characteristics.

4. according to user needs, the machine can use constant temperature cooling device and independent hydraulic station system, to ensure the processing accuracy and the stability of the technical indicators.

5. The column, beam, ram and other guide surface are hardened, grinding, artificial joint research, high precision, good quality.

6. The machine feed is driven by servo motor and ball screw, and the cross beam is equipped with a closed protective cover, which increases the safety and comfort of the machine.

7. CNC system can be imported or domestic according to user needs.

8. Optional configuration: electric cutter table, semi-closed shell, cooling chip removal device, two stepless speed regulation.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life