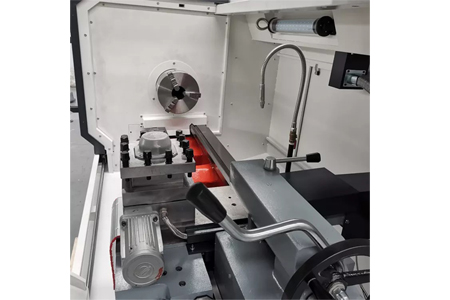

CK6136Q CK6140Q CK6150Q High Precision Efficient Metal Flat bed CNC Lathe

Swing over bed : 360-500 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Units | CK6136Q | CK6140Q | CK6150Q |

| Swing over bed | mm | 360 | 400 | 500 |

| Swing over cross slide | mm | 190 | 210 | 280 |

| Guide width | mm | 360 | 360 | 360 |

| Max.Work piece Length | mm | 650/850 | 1350 | 1850 |

| Spindle bore | mm | 52(Optional:82) | 52(Optional:82) | 52(Optional:82) |

| Spindle bore taper | – | C6/C8 | C6/C8 | C6/C8 |

| Spindle speed steps | – | Manual 2 steps (Optional: step-less) | Manual 2 steps

(Optional: step-less) |

Manual 2 steps (Optional: step-less) |

| Spindle speed range | rpm | 100-500-1800 | 100-500-1800 | 100-500-1800 |

| Turret/tool post | – | Electric 4 position | Electric 4 position | Electric 4 position |

| Tool size | mm | 20 x 20/20 x 20/25 x 25 | 20 x 20 | 25 x 25 |

| X axis travel | mm | 250 | 250 | 250 |

| Z axis travel | mm | 750/1000 | 1500 | 2000 |

| X axis rapid traverse | mm/min | 6000 | 6000 | 6000 |

| Z axis rapid traverse | mm/min | 8000 | 8000 | 8000 |

| Tail stock quill diameter | mm | 65 | 65 | 75 |

| Tail stock quill taper | – | MT5 | MT5 | MT5 |

| Tail stock quill travel | mm | 130 | 130 | 130 |

| Main spindle motor | kw | 5.5 | 5.5 | 7.5 |

| Weight for 750 | kg | 1600/1700/1800 | 1700 | 1800 |

| Weight for 1000 | kg | 2000 | 2100 | 2200 |

| Weight for 1500 | kg | 2300 | 2400 | 2500 |

| Weight for 2000 | kg | 2800 | 2900 | 3000 |

| Dimension for 750 | mm | 2060*1200*1500 | 2060*1200*1500 | 2060*1200*1500 |

| Dimension for 1000 | mm | 2310*1200*1500 | 2310*1200*1500 | 2310*1200*1500 |

| Dimension for 1500 | mm | 2810*1200*1500 | 2810*1200*1500 | 2810*1200*1500 |

| Dimension for 2000 | mm | 3210*1200*1500 | 3210*1200*1500 | 3210*1200*1500 |

Resources & Downloads:

CK6136Q CK6140Q CK6150Q High Precision Efficient Metal Flat bed CNC Lathe Product Introduction :

Product description

CK Series machine tools is a mature product has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.This series machine can automatically process the inside and outside cylinder surface, cone surface, circular arc surface, end face, such as processing, and also can process the single and multiple threads in metric, inch and other standards.

Features

1.A high strength,widening the carriage,suitable for heavy cutting.

2.four position electric turret

3.frequency conversion step-less speed regulation

4.standard configuration: manual Optional configuration:hydraulic chuck

Application

The machine is suitable to process all kinds of small and middle-sized shaft and plate work-piece,and could also turn various threads ,circle arc ,circle cone ,inside and outside surface of revolved body .This machine is widely used in sanitary ,value,electrical appliance ,instrument ,automobile ,motor cycle ,bearing and so on.

Standard accessories:

1.Coolant system

2.Lubrication system

3.3- jaw manual chuck

4.Electric turret 4 position

5.Manual tail-stock

6.Tool box and tools

7.GSK CNC system

Optional accessories

1.Automatic Feeding Device For Long Bar Work Piece

2.Chip Conveyor

3.Hydraulic Chuck

4.Electric Turret 6 Position

5.Siemens/Fanuc Control

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life