High precision CNC lathe

Modular design and configuration of 3 axis, 4 axis and 5 axis linkage function according requirements

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Type | CNC630 | CNC850 | CNC1000 | CNC1250 | |

| Main specification | Max swing over bed ( mm ) | ¢630 | ¢ 850 | ¢ 1000 | ¢ 1250 |

| Max machining diameter ( mm) | ¢630 | ¢850 | ¢ 1000 | ¢ 1250 | |

| Max swing over arriage ( mm ) | ¢430 | ¢630 | ¢850 | ¢1000 | |

| Max weight of workpiece ( kg ) | 1000/1 500/2000/3000/4000/5000 | ||||

| Max weight of workpiece ( kg ) | 2000 | 4000 | |||

| Spindle | Spindle nose | ISO A2-11 | ISO A2-11 | ISO A2-15 | ISO A2-15 |

| Diameter of spindle in front bearing ( mm ) | 160 | 160 | 200 | 200 | |

| Spindle hole ( mm ) | 95 | 95 | 120 | 120 | |

| Max. speed of spindle ( rpom ) | 2000 | 1500 | 1200 | 1200 | |

| Power of spindle servo motor ( kw ) | 26.5 | 38 | 45 | 45 | |

| Chuck diaetrthydraulic chuck is optioall | 15 | 18 | 20 | 20 | |

| Tail stock (Hydraulic programmable tailstck is optional) | Diameter of tail stock ( mm ) | ¢180 | ¢180 | ¢200 | ¢200 |

| Travel of tilstck ( mm ) | 160 | 160 | 200 | 200 | |

| Taper of tilstock | MT6 | MT6 | MT6 | MT6 | |

| Drive unit | Travel of X axis ( mm ) | 315 | 425 | 500 | 625 |

| Tavel of Z axis (mm) | 1050/1550/2 100/3100/4100/5100 | ||||

| Rapid traverse of X axis ( m/min ) | 10 (hard rail) / 20 (line rail) | ||||

| Rapid traverse of Z axis ( m/min ) | 10 (hard rail) / 20 (line rail) | ||||

| Feed rate of X axis ( m/min ) | 0.001-4000 | ||||

| Feed rate of Z axis( m/min ) | 0.001-4000 | ||||

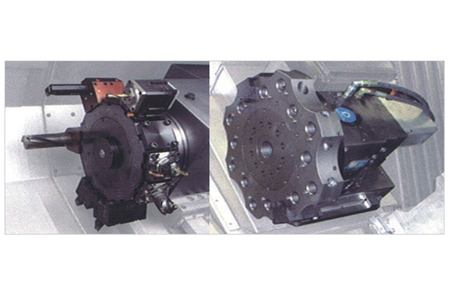

| NC horizontal turret (Servo power turret is optional) | Tool position | 12/8 | 12/8 | 12/8 | 12/8 |

| Section of tool shank ( mm ) | 25X25 | 32X32 | 40X40 | 40X40 | |

| Diameter of boring bar ( mm ) | 32 | 40 | 50 | 50 | |

| Choosing tool at the nearest distance | Yes | ||||

| System configuration | CNC system | SIEMENS 828D or FANUC 0I-TF | |||

| Servo motor for X axis | 27Nm | 38Nm | |||

| Servo motor for Z axis | 27Nm | 38Nm | |||

| Detecting unit | Optional | ||||

| Grating scale | Optional | ||||

| Encooder | Optional | ||||

| Tool setting | Optional | ||||

Resources & Downloads:

High precision CNC lathe Product Introduction :

Product description :

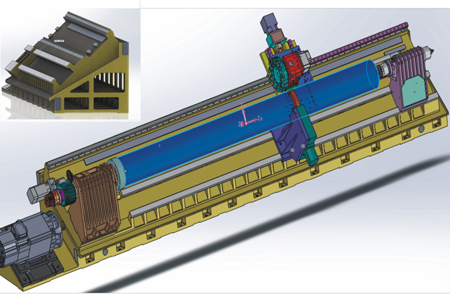

High precision CNC lathe, is a new generation CNC lathe which is fully absorbed in leading manufacturing technology in the world, on the basis of original SOMAB company manufacturing experience, independent developed by our Company. Modular design and configuration of 3 axis, 4 axis and 5 axis linkage function according to user requirements.

The material of bed is made of high strength HT300 and 45 degree integral casting, and the bed is in process of secondary anneal heat treatment, has characteristics of high precision and high stability. Can be equipped linear guide way, set of steel guide way or quenching guide way according to user’s requirement.

Uses high precision special bearing for spindle, reasonable equipping and span design, make the performance of high rigidity and high precision, and convenient to configure C axis function, cooperate with the power tool post to realize milling and turning function according to requirement, and can configure the hydraulic power chuck, 3-jaw self-centering chuck.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life