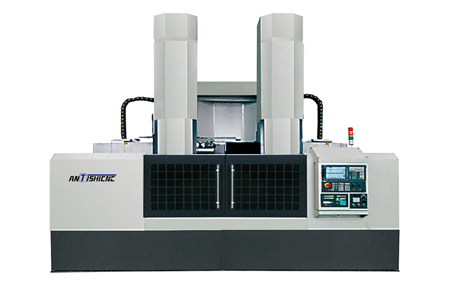

CKM51 series single column numerical control vertical turning and grinding compound machine

Max turning dia. : 2600mm

Max workpiece height : 1600mm

Max workpiece weight : 12t

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specification | Unit | CKM5116 | CKM5120 | CKM5123 | CKM5126 |

| Maximum turning diameter | mm | 1600 | 2000 | 2300 | 2600 |

| Table diameter | mm | 1400 | 1800 | 2000 | 2250 |

| Maximum workpiece height | mm | 1000/1400 | 1200/1400 | 1200/1400 | 1400/1600 |

| Maximum workpiece weight | t | 8 | 10 | 10 | 12 |

| Maximum Torque of table | KN.m | 25 | 32 | 35 | 35 |

| Working table speed range(4steps) | r/min | 1-200 | 1-120 | 1-100 | 1-63 |

| Feed Range of tool rest (stepless) | mm/min | 0.1-500 | 0.1-500 | 0.1-500 | 0.1-500 |

| Horizontal travel of raihead | mm | 915 | 1050 | 1180 | 1330 |

| Ram travel with vertical tool rest | nun | 800 | 800 | 1000 | 1000 |

| Knife model | Square ram/four-station electric knife table | ||||

| Power of main motor | KW | 30 | 30 | 30 | 37 |

| Power of electric grinding head | KW | 5.5-7.5 | 55-7.5 | 5.5-7.5 | 5.5-7.5 |

| Rotating speed of electric grinding head | r/min | 50-3000 | 50-3000 | 50-3000 | 50-3000 |

| Diameter range of grinding wheel | mm | 200-400 | 200-400 | 200-400 | 200-400 |

| Grinding ovality | mm | W0.01 | W0.01 | W0.01 | W0.01 |

| Grinding cylindricity | mm | 0.01/300 | 0.01/300 | 0.01/300 | 0.01/300 |

| Positioning accuracy | mm | 0.02 | 0.02 | 0.02 | 0.02 |

| Repeated Positional accuracy | mm | 0.015 | 0.015 | 0.015 | 0.015 |

| Overall dimensions(L x WxH) | mm | 6000x3800x3500 | 6400x4000x3750 | 6700x4100x3900 | 7000x4250x3900 |

| Weight of machine(Approx) | t | 22/26 | 26/28 | 30/32 | 34/36 |

Resources & Downloads:

CKM51 series single column numerical control vertical turning and grinding compound machine Product Introduction :

1.CKM51 series of single column numerical control vertical turning and grinding compound machine tools, which are developed by our company with advanced level at home and abroad. Suitable for machinery manufacturing industry and valves, auto parts, abrasives, aerospace, military products and other industries.

2. The beam is equipped with two CNC tool holder, the right tool holder is the tool holder, the left tool holder is the grinding tool holder, and the workpiece is once installed and processed to achieve two processes of turning and grinding, improving work efficiency and reducing costs. Improve machining accuracy and reduce labor intensity.

3. The grinding head adopts electric spindle structure, the electric spindle is installed at the lower end of the ram, and the water cooling method is adopted to make the electric spindle run for a long time, ensuring the grinding head running speed, low noise, large torque and good stability.

4. The work table is thermally symmetrical. The main shaft adopts high-precision adjustable radial clearance double-row short cylindrical roller bearing centering in radial direction, high-precision thrust bearing rolling guide rail in axial direction, and the guide rail can also use cross roller bearings.

5. For 650mm wide beam guide rail using four-point hydraulic lock, the top two ends of the column using AC motor, transmission transmission, through the double screw pull lifting beam, so that the beam increase the stability of lifting, to ensure the accuracy of the machine tool.

6. Column, beam guide surface high-frequency quenching, hardness HRC48-55 degrees

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life