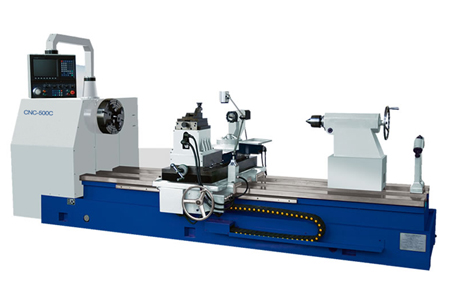

CNC-500C Roll Notching And Marking Machine

Processing Roll dia. : 50 - 500mm

Processing Roll Max. length : 2500mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Main specifications and technical parameters | |

| Processing roll maximum diameter | 500mm |

| Minimum diameter | 50mm |

| Processing roll maximum length | 2500mm |

| The maximum length of the processing roll surface | 1800mm |

| Processing of the crescent specification | Φ6~Φ50 |

| Processing the crescent β angle Any | Any |

| Processing the crescent slot | Any |

| Lateral moving speed (X axis) | 0~6000mm/min |

| Workpiece rotation speed (Y axis) | 0~30rpm |

| Swing head rotation speed (Z axis) | 0~50rpm |

| Flying cutter milling speed (A axis) | 0~600rpm |

| Engraving head motor model rated speed | D85 24000rpm |

| Cooling pump motor | AB25-90W |

| Control System Siemens | Siemens808D |

| Servo motor rated power | X axis 1.75kw |

| Y axis 2.5kw | |

| Z axis 1.75kw | |

| A axis 3.5kw | |

| Minimum programming amount | 0.001 |

| Longitudinal magnetic scale effective measurement length | 2000mm |

| grating accuracy | 0.005mm |

| chuck form four claws | Four chuck |

| Chuck diameter | 400mm |

| Machine working power supply | 380V,50HZ;15KVA |

| Dimensions | 4500×1700×2000mm |

| Machine Tool Net | 6T |

Resources & Downloads:

CNC-500C Roll Notching And Marking Machine Product Introduction :

Products Description

1.The ANTS CNC-500C machines are versatile multi-functional machine, which performs the notching, milling and marking operation in the same machine within same working procedure. CNC-500C machines have been proved to be high automatic, high precision, high efficiency and good safety.

2.The heavy-duty CNC-500C machines are built with three guides structure. The width reaches 910mm and the bed saddle reaches 810mm which highly improve the machines’ rigidity and vibration resistance. These ensure CNC-500C can mill steel rolls and tungsten carbide rolls in high speed.

3.High efficiency machining, milling 1 ring groove in about 15 minutes, engraving and milling marker in about 10 minutes, can also be less.

4.Milling transverse rib groove angle in the standard range of arbitrary choice, can also be any empty slots.

5.The steel used in CNC-500C machine body are treated by ageing or annealing. The guideways are treated by intermediate frequency quenching to increase the surface abrasion resistant. A rolling linear guide rail is employed for lateral feed to reduce friction and assure the high speed and precision. Under the normal condition, the linear guide has 10 years guarantee.

6.Machine tool assembly manual aligning cutter mechanism, and the saddle longitudinal movement with grating digital display, ensure the manual change slot displacement is accurate, eliminate the human visual caused by touching the edge cutting knife phenomenon.

7.Control uses SINUMERIK 808D system, LCD display, can realize any of three axes linkage.Full servo system of machine tool, 4 control axis are independent motor and drive. The system has good dynamic quality, implementation of the selected servo system of high precision, good reliability, strong anti-interference ability, fast response speed. User friendly , Enables faster change of branding with use of software.

8.Designed specifically for the international market, can process all international standards. Such as: GB (China standard), BS (British Standard), JIS (Japanese standard) ASTM (American standard) IS (India standard), ISO6935-2 (International Standard) and customer local standards.

9.The machine has the operability, maintainability and good safety performance, should not pollute environment and harm human body health.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life