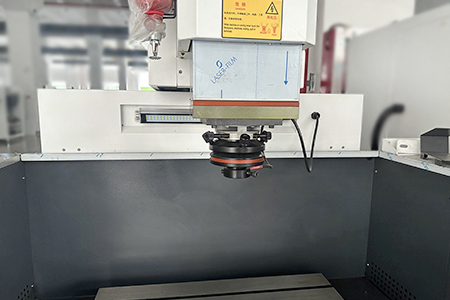

CNC Die Sinker EDM Machine 540K/650K

X-axis travel : 500mm/600mm

Y-axis travel : 400mm/400mm

Z-axis travel : 300mm/350mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | 540K | 650K |

| Working tank size (L*W*D) | 1300*920*500mm | 1612*985*540mm |

| Worktable Size(L*W) | 800*500mm | 900*500mm |

| X-axis travel | 500mm | 600mm |

| Y-axis travel | 400mm | 400mm |

| Z-axis travel | 300mm | 350mm |

| Accessory mounting plate to work surface distance | 300-600mm | 350-700mm |

| Max.work piece weight | 1800kg | 2000kg |

| Maximum electrode weight | 50kg | 70kg |

| Dimensions (L*W*H) | 1640*1050*2150mm | 2000*2320*2530mm |

| Machine weight | 3800kg | 4000kg |

| The input power of the whole machine | 9kw | 9kw |

| Max. machining current | 50A | 50A |

| Maximum processing power | ≥500mm³/min | ≥500mm³/min |

| Minimum electrode loss | 0.10% | 0.10% |

| Best surface roughness | Ra≤0.1mm | Ra≤0.1mm |

| Minimum mechanical drive equivalent | 1μm | 1μm |

| Resolution of each axis | 0.4 | 0.4 |

| Input | USB device, touch screen | USB device, touch screen |

| Position command method | Incremental/Absolute | Incremental/Absolute |

| EDM condition registration function | 1000 conditions can be registered C000-C999 | 1000 conditions can be registered C000-C999 |

| Bias function | 1000 offsets can be registered H000-H999 | 1000 offsets can be registered H000-H999 |

| Subroutine nesting level | 50 | 50 |

| Q instruction nesting level | 7 | 7 |

| Number of coordinate systems | 60 | 60 |

Resources & Downloads:

CNC Die Sinker EDM Machine 540K/650K Product Introduction :

Equipment Introductions

Shanghai ANTISHICNC “540K” is a bullhead full CNC EDM machine tool, with three-axis arbitrary axis to achieve high-precision machining in the “positive and negative” directions with a minimum feed size of “1 micron” (the fourth axis can be selected ), to achieve high-precision translational processing on any axis and other axes, and to realize more axis-linked processing. Each axis is driven by fully imported AC servo motors and precision ball screws to achieve higher machine tool precision control and processing speed.

Equipped with ANTISHICNC “A2S-50” CNC power supply with high stability and high anti-interference ability, you can obtain extremely low EDM electrode loss, so that your mold processing precision is higher and the service life is longer.

Features

1. Overall structure: Based on the bullhead frame structure, the worktable does not move during processing, ensuring high responsiveness when processing large work pieces.

2. Castings: The castings of the whole machine are made of high-quality resin sand materials, which have undergone multiple annealing stress treatments to ensure the best precision and durability, and will not deform for a long time.

3. Each axis is directly driven by AC servo motor and precision ball screw.

4. Each machine tool has been strictly inspected by the British Renishaw laser interferometer.

Standard Equipment

EDM Machine

Working fluid tank

Infrared touch screen input system

TFT-LCD 15 inch liquid crystal display

Standard Toolbox and Fixtures

Bolts for adjusting the level of the main engine, parallel irons for adjusting the level of the main engine

User’s manual

Electronic disk device

X, Y, Z axis AC servo machine, encoder

Hand control box

Finishing loop

Genuine software of EDM CNC system

USB standard interface, RJ45 (network port), PS2

Carbide-specific processing circuit (explosion-increasing circuit)

AUTO (automatic processing) unit

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life