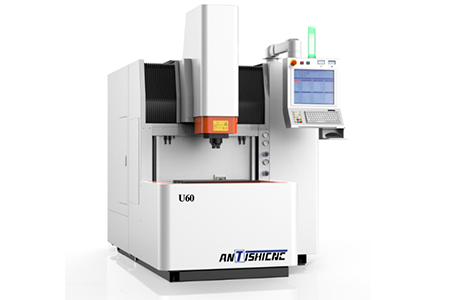

U60 CNC Mirror Discharge Die Sinker EDM Machine(A3-50 system)

X-axis:600mm

Y-axis:400mm

Z-axis:400mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | U60 |

| Size of working fluid tank (length, width and depth) | 1280*1040*450mm |

| Table (length and width) | 850*600mm |

| X-axis | 600mm |

| Y-axis | 400mm |

| Z-axis | 400mm |

| The distance between the electrode plate and the table | 300-700mm |

| Maximum weight of table | 1800kg |

| Maximum electrode weight | 50kg |

| X/y/z positioning accuracy | ≤0.006mm |

| X/y/z repeated positioning accuracy | ≤0.003mm |

| Minimum additional size | ≤0.005 mm |

| Shape size (length, width and height) | 2040*2800*3100mm |

| Weight of machine | 5500kg |

| Input Power of the whole machine | 9kw |

| Maximum machining current | 50A |

| Maximum processing power | ≥500mm³/min |

| Minimum electrode loss | 0.1% |

| Best Surface Roughness | Ra≤0.07m |

| Minimum angle loss | ≤20m |

| The smallest line discharge | ≤0.05mm |

| Means of communication | Ethercat bus |

| Servo type | Ethercat bus |

| Motion acceleration mode | Strong set S-type |

| Minimum control current | 0.1A |

| Minimum pulse width | 0.25s |

| Minimum mechanical drive equivalent | 0.1m |

| Resolution | 0.1m |

| Input mode | Keyboard, mouse, touch screen |

| Position Instruction mode | Incremental/absolute |

| EDM condition log function | Can Register 1000 conditions C000-C999 |

| Biasing function | 1000 H000-H999 offsets are available |

| Number of coordinate systems | 60 |

Resources & Downloads:

U60 CNC Mirror Discharge Die Sinker EDM Machine(A3-50 system) Product Introduction :

Equipment Introductions

ANTISHICNC “U60″ is the only domestic use of Swiss advanced technology, combined with their own innovative technology and build a lifting tank mirror CNC EDM machine , it is the most advanced CNC mirror EDM machine in China, which can realize three or more axis linkage machining, and any axis can realize”Positive and negative” direction machining, all three axes are directly driven by imported precision ball screw and AC servo motor, and the lifting shaft of liquid tank is controlled by closed-loop servo drive to realize arbitrary machining height control.

High performance, high stability, high anti-interference Linux operating system control power supply, to achieve high efficiency, high finish, ultra-low electrode loss of discharge processing, at the same time to achieve high-precision micron-level continuous depth of processing control, machine processing accuracy, precision retention and processing index can be comparable to imported machine s, is your best choice to replace imported high-end CNC Spark Machine.

At the same time, it has automatic changing device and automatic changing function outside the machine. It can be fully automatic with machining center, high-speed machine and other machining equipment, realize unmanned operation processing.

Features

Mechanical part

1.Overall structure: Based on Swiss, Japan high-end lifting tank spark mechanical structure, the body, electric cabinet and electric cabinet for the Integrated Design, covers a smaller area, can be fully automated, unmanned operation control.

2.Casting: high quality resin sand casting with Swiss standard, after repeated annealing, vibration failure stress treatment, to ensure the best precision and durability of the fuselage, long-term use without deformation.

3.Precision Drive components: Precision Ball Screw, Precision Roller Guide, precision bearings and other high-precision control components are designed and customized by Swiss AGIE CHARMILES, once again, the accuracy of the machine , operational responsiveness and long-term use of the accuracy of the maintenance to a higher platform.

3.Each axis drive: AC servo motor and precision ball screw direct drive, while the main shaft used high-power AC servo motor. Higher torque, better high speed response.

4.Assembly process: in strict accordance with Swiss AGIE CHARMILES manufacturing process, assembly process, manufacturing standards, precision standards, etc.

5.Precision Testing: all machine casting and components are processed by German Zeiss coordinate measuring instrument for strict testing, to ensure the high precision of each component. Then through the British Renishaw Laser interferometer for each machine for strict precision testing, and so on, so that the machine accuracy and stability.

6.Lifting tank: CNC servo control tank lifting, can achieve arbitrary height control of the workpiece. Adopt double pump control, better filtering effect, faster oiling speed.

7.Compactness: fuselage, fuel tank, electric cabinet integrated design, better compactness, small footprint

8.It is the only substitute for imported high-end spark machine products.

| Key components of machine | Brand | Place of origin |

| Machine casting | High quality resin sand in Swiss | China |

| X, y, z three axis guide rail | Roller linear guide rail | HIWIN/THK |

| Three-axis AC servo motor | Panasonic | Japan |

| Three-axis AC servo drive | Panasonic | Japan |

| LCD screen | 17-inch industrial grade | Taiwan,China |

| Switch power level, brand | Industrial Grade, MINGWEI | Taiwan,China |

| Brand of contactor | High Standard Schneider | France |

| Air Switch | Schneider | France |

| Communication wire and cable | Industrial grade double shielded network cable | China |

| Integrated circuit chip brand | NXP/ATMEL/ALTERA, etc. | Abroad |

| Middle Relay brand and emergency stop | IDEC | Japan |

| Brand name of optocoupler device | Toshiba | Japan |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life