CS6250B Universal Lathes

Max swing over bed : Φ500 mm

Max swing in gap : Φ710 mm

Max workpiece length : 3000mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Item | Unit | Parameter | |

| CS6250B Lathe | |||

| Capacity | Max swing over bed | mm | Φ500 |

| Max swing in gap | mm | Φ710 | |

| Effective length in gap | mm | 240 | |

| Max swing over slide | mm | Φ300 | |

| Max workpiece length | mm | 1000/1500/2000/3000 | |

| Spindle | Spindle thru-hole | mm | Φ82 |

| Spindle nose | ISO 702/Ⅱ No.8 cam-lock type | ||

| Spindle speed | r/min | 24 step 9-1600 | |

| Spindle motor | kW | 7.5 | |

| Tailstock | Quill dia./travel | mm | φ75/150 |

| Taper of center | MT | 5 | |

| Tool post | Number of station/ Tool section | 4/25X25 | |

| Feed | Max X-axis travel | mm | 145 |

| Max Z-axis travel | m/min | 320 | |

| X-axis feed | mm/r | 93 sorts 0.012-2.73 | |

| Z-axis feed Z-axis feed | mm/r | 93 sorts 0.028-6.43 | |

| Metric thread | mm | 48 sorts 0.5-224 | |

| Inch thread | t.p.i | 46 sorts 72-1/8 | |

| Module thread | πmm | 42 sorts 0.5-112 | |

| DP thread | t.p.i. π | 45 sorts 56-1/4 | |

| Others | Coolant pump motor | kW | 0.12 |

| Machine length | mm | 2632/3132/3632/4632 | |

| Machine width | mm | 975 | |

| Machine height | mm | 1270 | |

| Machine weight | kg | 2050/2200/2600/2900 | |

Resources & Downloads:

CS6250B Universal Lathes Product Introduction :

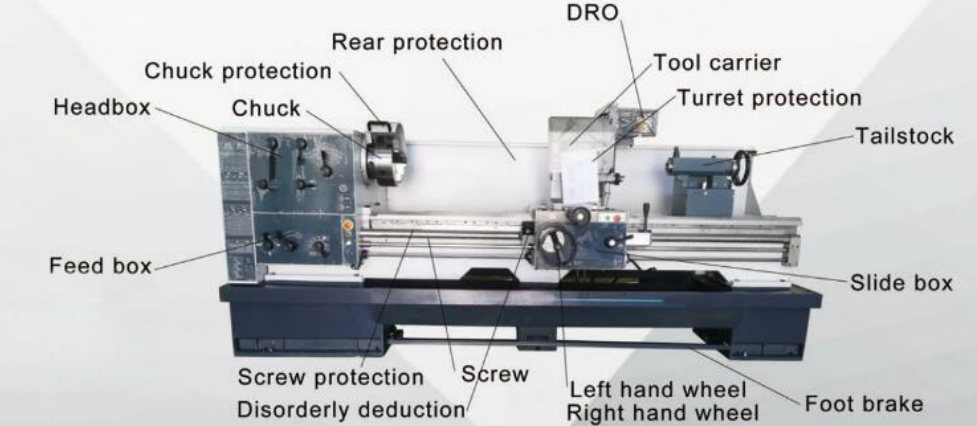

Equipment Introductions

1. CS6250B Lathe can perform internal and external turning, taper turning, end facing, and other rotary parts turning;

2. Threading Inch, Metric, Module and D.P. ;

3. Perform drilling, boring and groove broaching;

4. Machine all kinds of flat stocks and those in irregular shapes;

5. Respectively with through-hole spindle bore, that can hold bar stocks in larger diameters;

6. Both Inch and Metric system are used on these series lathes, it’s easy for people from different measuring systems countries;

7. High anti twist water flat bed, high quality cast iron is carefully manufactured, and the guide surface is treated with intermediate frequency induction quenching precision;

8. The guide rail pair composed of polymerizing tetrafluoroethylene guide rail soft belt has good wear resistance, vibration absorption and precision retention;

9. The spindle adopts three support structure, with good rigidity, high precision and strong cutting;

10. Wide speed regulation range and reasonable speed can be selected;

11. lt can directly turn metric and inch threads;

12. In addition to conventional turning, saddle lathe can also turn all kinds of flat and special-shaped parts;

13. These series lathes operate on power supply of different voltages (220V,380V,420V) and different frequencies (50HZ,60HZ).

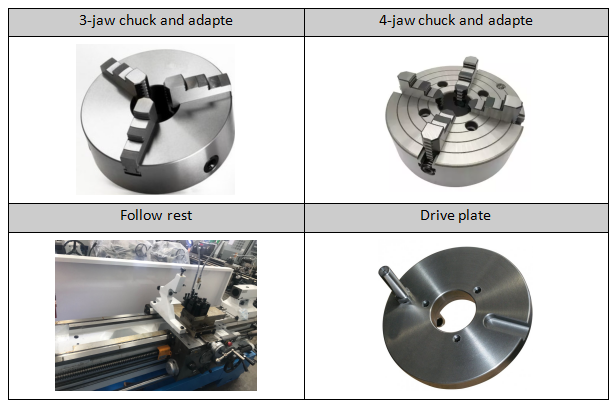

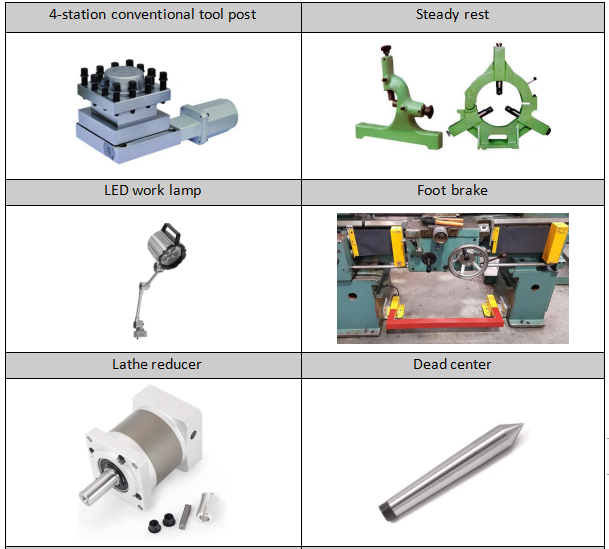

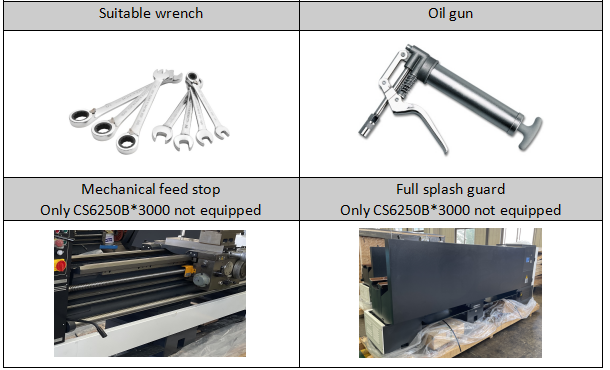

Standard Equipment

Optional Equipment

| NO. | Name |

| 1 | Living center |

| 2 | Faceplate |

| 3 | Chuck protection |

| 4 | Tool post protection |

| 5 | Mounting pad and foot blot |

| 6 | Curtain three bar protection |

| 7 | Taper turning attachment |

| 8 | Thread chasing dial |

| 9 | Quick change tool post Italy type |

| 10 | Digital readout(2 AXIS) |

| 11 | Digital readout(3 AXIS) |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life