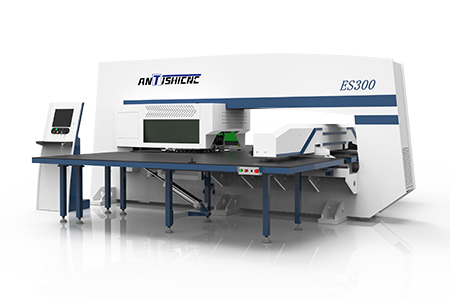

ES300 Full Servo CNC Turret Punch Press

Max. Sheet Thickness: 6.35mm

Max. Diameter: Φ88.9mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| NO. | Name | Specification | Unit | |

| 1 | Press Capacity | 300 | KN | |

| 2 | Transmission Type | Servo | ||

| 3 | Frame Construction | O-frame | ||

| 4 | Max. Sheet size | X axis | 5000 (With one re-positioning) | mm |

| Y axis | 1250□ 1500□ 2000□ | mm | ||

| 5 | Max. Sheet Thickness | 6.35 | mm | |

| 6 | Max. Diameter | Φ88.9 | mm | |

| 7 | Max. Punching Stroke | 32 | mm | |

| 8 | Max. Nibbling Speed | 1500 | hpm | |

| 1mm pitch, 6mm punch stroke | 750 | hpm | ||

| 25.4mm pitch, 4mm punch stroke | 400 | hpm | ||

| 9 | No. of Clamps | 3 | pcs | |

| 10 | No. of Re-positioning Cylinder | 2 | set | |

| 11 | Turret Stations | 32 | pcs | |

| 12 | No. of Controlling Axis | 5(X, Y, T, C, A) | pcs | |

| 13 | Tool Distribution | 16A/ 12B/ 2BZ/2C /2D | ||

| 14 | Worktable Structure | Brush and ball mixed | ||

| 15 | Max. Feeding Speed | X axis | 80 | m/min |

| Y axis | 80 | m/min | ||

| X, Y combined | 110 | m/min | ||

| 16 | Turret Speed | 30 | rpm | |

| 17 | Rotational Tool Speed | 40 | rpm | |

| 18 | Punching Accuracy | ±0.10 | mm | |

| 19 | Max. Sheet Weight | 150 | kg | |

| 20 | Air Pressure | 0.6 | mpa | |

| 21 | Power | 63 | kw | |

| 22 | Clamp Dead Area Detection | Yes | ||

| 23 | Clamp Splint Loose Alarm Device | Option | ||

| 24 | Plate Warping Alarm | Yes | ||

| 25 | Clamp Automatically Float Down | Yes | ||

| 26 | Roller Auxiliary Feeding | Yes | ||

| 27 | Overall Size | Length | 5170□ 5670□ 6670□ | mm |

| Width | 5200□ 5200□ 5200□ | mm | ||

| Height | 2300□ 2300□ 2300□ | mm | ||

Resources & Downloads:

ES300 Full Servo CNC Turret Punch Press Product Introduction :

Frame

O-type closed integral welding press frame special for servo punch press. Holistic welding structure, stress relief from tempering treatment. The strong rigidity and high tonnage ensure the stable accuracy for long time, extend the service life of the machine and tools, and improve the positioning precision, reliability and durability.

Servo Transmission Technology

Rexroth punch motor, full electro technology, no any hydraulic involved. Servo direct drive main transmission, tonnage. Sealed oil tank type, good lubrication, low heat generation, insert installation. With rolling rib, lettering, knock-down hole, stretching, louver, trimming and cutting angle, forming function.

Feeding System

Rexroth feeding motors, ball screw and guide liner The big space between guider will benefit with processing accuracy while fabricate large size sheet, and it has the better balance capacity while moving in high speed. The auxiliary platform can move with the sheet, reduce 30% of the friction force between the plate and brush platform. Line guider and ball screw import from or German Rexroth, ensure the accuracy and long service life. The imported pneumatic, and electric parts ensure the overall performance reliability. Centralized lubricating system, reduce the friction of all moving parts, prolong the service life of the machine.

Worktable

The worktable surface with hard brush and steel ball, to lower down the noise while working and protect the surface of the sheet. Seamless worktable design to avoid collision during sheet metal movement. Folding table design, side auxiliary platform automatic folding control, easy to change tooling. Aluminum edging design, side aluminum edging, protect the worktable surface from wear. Side loading auxiliary roller, easy to loading the plate.

Floatable Pneumatic Clamps

The pneumatic floatable clamps reduce the deformation of the plate. The self-protection function makes no dead area for punching on sheet. The clamp automatically floats when clamping the plate, convenient for the plate clamp. Automatic unloading when the clamp returns.

Full Auto Indexed Station

Unique worm gear structure to ensure the accuracy of positive and negative bidirectional transmission. Single import synchronous belt drive to ensure synchronization between up and down.

Turret and Tooling

Precision wear-resistant guide holder inlaid on turret, large machining center in pairs processed International standard Japan AMADA long guide tool, Reasonable stations distribution, tooling in common use.

ANTISHICNC CNC System BEST FOR OPERATOR

Network communication, software can infinitely speed variation. Real-time display of machining graphics, intuitive and humanized interface. With one key to return to the reference point function, can set a key loading positions. According to the plate thickness automatic adjust the punch preloading height. Can set high precision, extreme speed, normal and so on many kinds of processing mode. Automatic detection of clamp position. Break point processing function, analog processing function. One key operation, cycle start function. All stations have their own independent protection area, and own independent processing parameters. Field programming, background programming.

| Name | Model | Supplier |

| CNC System | IPC-WMCW03 | ANTISHICNC |

| Servo Motor | X- Axis MDMF502L 1G6M | Japan Panasonic |

| Y- Axis MDMF752L 1G6M | ||

| T- Axis MDMF202L 1G6M | ||

| C- Axis MDMF152L 1G6M | ||

| A- Axis EMT2-63kW-1500Nm | ESTUN /PHASE | |

| Bearing | Tapered Roller Bearings 32220 | Germany Leipzig |

| Synchronous Tooth Belt | 8M Timing Belt | Germany Continental |

| Coupling | Y25T/42T | Japan MIKI PUllEY |

| Y25T/35T | ||

| Line Guider | R205540331-2450 | Germany Rexroth/Japan THK |

| R205530331-4000 | ||

| R205570331-3000 | ||

| Ball Screw | R40-40K2-FSC-1881 | Germany Rexroth/Japan THK |

| R40-40K2-FSC-2900 | ||

| Air Source Treatment Quadreple | GFC300-10 | Airtac |

| SMC | 4V220-08 | |

| Two-Position Ttree Way Magnetic | 4V210-08 | |

| Reduction | VRBZ-140 | Japan Shimpo |

| Breaker | ABS53B 40A | KOREA LS |

| Contactor | LC1E160M5N | France Schneider |

| Button | YW1B-M1E10 | Japan IDEC |

| Chain | 16A | Japan Tsubaki |

| Cooling System | MCW-35C | Tongfei/Winhee |

| Drag Chain | 17X25-1700/680 77X26-1700 | Germany IGUS |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life