FX27-60 High Precision Traditional Cylindrical Grinder

Bench rotation : 270mm

Spacing between two centers :

600 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Machine specification | |||

| Processing capacity | Project | Unit | FX27-60 |

| Bench rotation | mm | 270 | |

| Spacing between two centers | mm | 600 | |

| maximum weight of the workpiece (with thimble) | kg | 60 | |

| maximum weight of the workpiece (single work head) | kg | 20 | |

| Grinding wheel and feed | Angle of rotation (left/right) | ±15° | |

| Standard grinding wheel size (outer diameter * width * inner diameter) | mm | 405×32-50×127 | |

| Special grinding wheel size (outer diameter * width * inner diameter) | rpm | 1650/1850/2100 | |

| Grinding wheel shaft speed | mm | 270 | |

| Moving distance | mm | 40 | |

| Rapid feed stroke (hydraulic automatic) | mm | 20 | |

| Spindle stroke (feed per revolution) | mm | ||

| Spindle stroke (per differential feed) | mm | ||

| Head frame | Spindle rotation mode | ||

| Worker rotation angle | 30° | ||

| Angle of rotation of the grinding wheel | |||

| Spindle speed | MT-4 | ||

| Thimble taper | 90° | ||

| Diameter of spindle through hole | mm | 25 | |

| Tailstock | Spindle travel | mm | 32 |

| Taper thimble | MT-4 | ||

| Workbench | Work rotation angle | 6° | |

| Angle of rotation of the grinding wheel | 9° | ||

| Handwheel per revolution feed | mm | 12.5 | |

| Automatic feed rate | mm/min | 50-4000/min | |

| Internal control grinding device | Spindle speed | rpm | 20000(30000) |

| Motor | kw(HP) | 0.75(1) | |

| Motor | Grinding wheel shaft | kw(HP) | 3.75 |

| Work head spindle | kw(HP) | 0.75 | |

| Hydraulic power circulation pump | kw(HP) | 0.75 | |

| Static pressure spindle oil pump | 1.5 | ||

| Grinding tank | kw(HP) | 0.37 | |

| Box capacity | Static pressure spindle tank (optional) | L | 120 |

| Hydraulic power circulation tank | L | 70 | |

| Grinding fluid tank | L | 200 | |

| Others | Mechanical device space (length * width * height) | mm | 2700×1520×1650 |

| net weight | kg | 2500 | |

Resources & Downloads:

FX27-60 High Precision Traditional Cylindrical Grinder Product Introduction :

Product description :

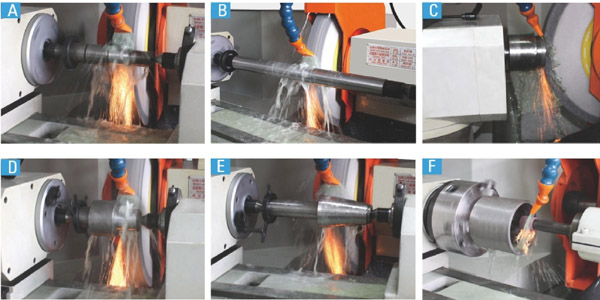

A、Straight Grinding

In small production, the automatic feed is combined with the non-sparking timer for good grinding quality. In the case of mass production, the automatic outer diameter measuring device (special accessory) is installed to provide the best output and grinding effect (CNC model)

B、Cross-grinding

The automatic intermittent feed and hydraulically driven table allow the workpiece to be effectively ground.

C、Face Grinding

Remove the rotating cover of the working spindle head and replace it with a three-jaw or four-jaw chuck. Change the position of the positioning tip to rotate the chuck and fix it at 90 degrees for end grinding.

D、Shoulder Grinding

When the outer diameter of the workpiece and its shoulder need to be finished once, the workpiece is supported by two centerings and the grinding wheel is modified to the right of the grinding wheel head and rotated at an angle to grind.

E、Slope Grinding

The work object can be supported by the chuck or the two centerings, and the work bench and the grinding wheel head can be rotated and adjusted easily

F、Inner Diameter Grinding

Grinding the inner diameter of the inner diameter grinding attachment (special accessory), as long as the inner diameter grinding spindle is pulled down and fxed in the grinding position, it can be ground.

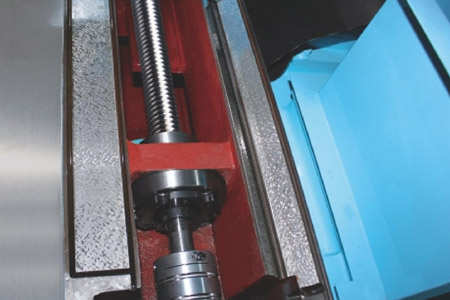

Specially Designed Grinding Wheel Spindle

The line speed can be adjusted from 35m/s to 60m/s in the case of adding a frequency converter. It has a great efficiency in grinding ultra-hard parts such as tungsten steel and ceramics.

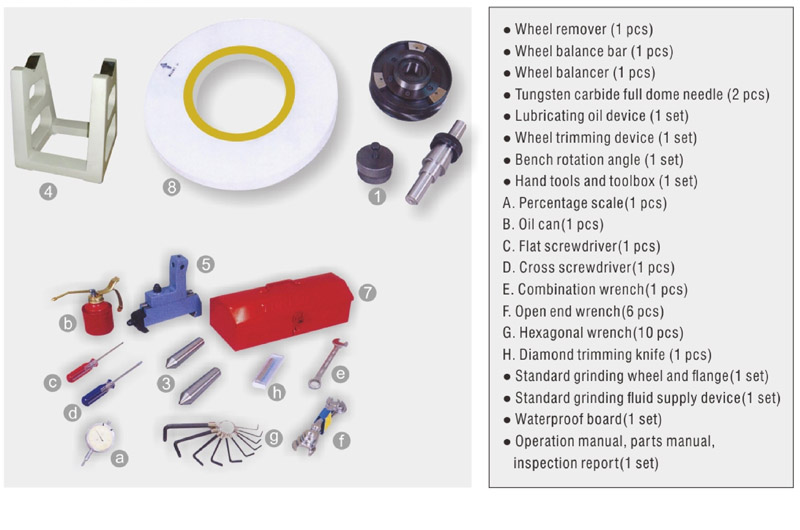

Standard Equipment

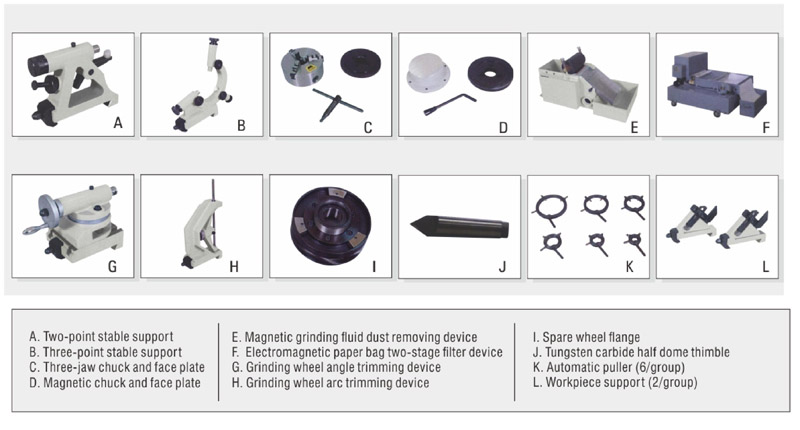

Optional Equipment

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life