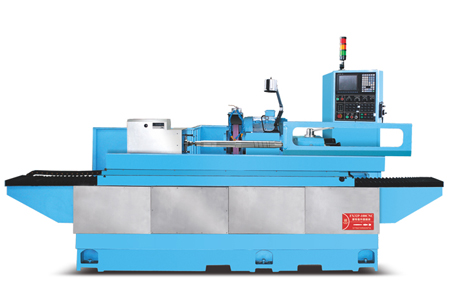

FX32P-100CNC Straight Feed CNC Cylindrical Grinder

Max rotating dia. : 350mm

Center distance : 1060 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| NO. | ITEM | Unit | Machine Mode:FX32P-100CNC | |

| Processing capability | 1 | Maximum rotating diameter of worktable | Mm | 350 |

| 2 | The longest distance between two Centres | Mm | 1060 | |

| 3 | Maximum grinding diameter | Mm | 320 | |

| 4 | Maximum load between two top centers | Kg | 150(Center works)

40(Only headstock) |

|

| 5 | Grinding wheel size (diameter × width × aperture) | Mm | 510×50×203.2/610×110×203.2 | |

| 6 | Wheel speed | Rpm | 1570/1742 | |

| 7 | Maximum linear speed of grinding wheel | m/s | 45 | |

| Wheelhead | 8 | Wheel dressing | Mm | Automatic |

| 9 | X axis minimum feed | Mm | 0.001 | |

| 10 | Feed angle | Deg | 90 | |

| 11 | Feed stroke | Mm | 320 | |

| 12 | X axis feed speed | m/min | 6 | |

| Headstock | 13 | Spindle speed | Rpm | 10-500 |

| 14 | Spindle form | Synchrony or centering | ||

| 15 | Thimble specifications | MT-5 | ||

| Tailstock | 16 | Automatic telescopic distance | Mm | 40 |

| 17 | Thimble specifications | MT-5 | ||

| 18 | Way of working | Manual/hydraulic | ||

| Workbench | 19 | Z axis fast moving speed | m/min | 8 |

| 20 | Z axis minimum feed | Mm | 0.001 | |

| 21 | Maximum travel stroke | Mm | 1300 | |

| 22 | Rotation angle | Deg | +7/-3 | |

| Motor | 23 | Wheel spindle motor | KW | 7.5/11 |

| 24 | X axis feed motor (servo) | KW | 3.0 | |

| 25 | Z axis feed motor (servo) | KW | 3.0 | |

| 26 | Headstock spindle motor | KW | 1.5 | |

| 27 | Cooling water pump motor | KW | 0.75 | |

| 28 | Lubricating oil motor | KW | (0.25)*2 | |

| 29 | Tailstock oil pump motor (special) | KW | 0.75 | |

| Others | 30 | X/Z axis guide/screw lubrication oil | MOBIL#1409 or ISO VG68 same level oil | |

| 31 | Machine net weight | Kg | 7500 | |

| 32 | Gross weight | Kg | 8500 | |

| 33 | Packing size (length * width * height) | Mm | 4800*3800*3000 |

Resources & Downloads:

FX32P-100CNC Straight Feed CNC Cylindrical Grinder Product Introduction :

Product description :

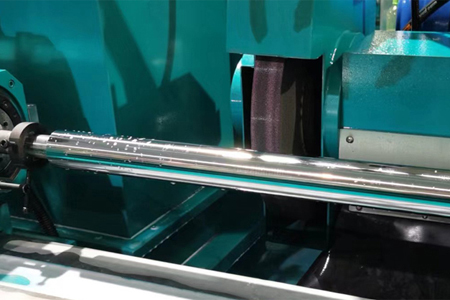

● The grinding wheel spindle has high rigidity, high precision, high service life and low vibration,and low friction.

● The self-aligning function, the wheel spindle is not affected by the belt tension and is biased.

● The spindle has a centering and simultaneous compound function, and the user can perform rapid conversion in the core machining and the chuck clamping process.

● The Z-axis consists of an AC servo motor, a high-precision bead screw, and an automatic forced lubrication system.

● High repeatability, long track service life, high rigidity and smooth reciprocating motion.

● Configurable surface measurement, outer diameter thickness measurement, grinding wheel anti-collision device.

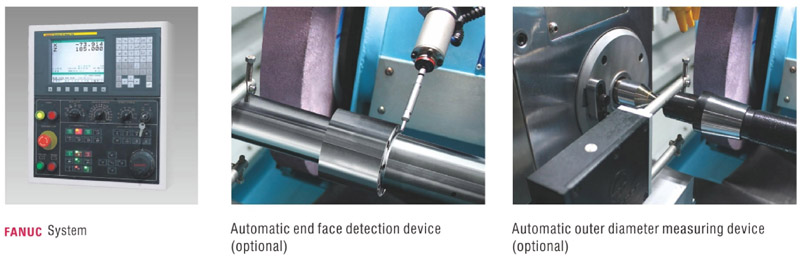

Optional Equipment

1. Inner hole grinding device

2. Automatic traction device

3. Automatic outer diameter measuring instrument

4. Automatic end face measuring instrument

5. Magnet + paper tape filter device

6. 6-inch three-jaw chuck and face plate

7. Spare grinding wheel flange

8. Tungsten carbide semicircular center

9. Full cover sheet metal

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life