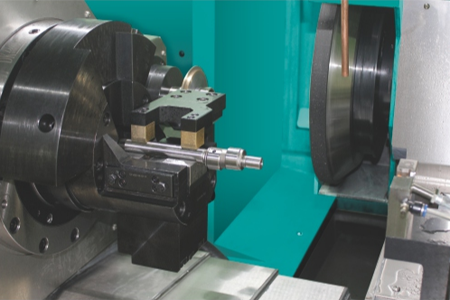

J2 Air conditioner refrigerator compressor crankshaft grinder

Max grinding length : 300mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| NO. | ITEM | Parameter |

| 1 | The center height of the spindle relative to the bottom of the base | 435mm |

| 2 | Maximum grinding work-piece length | 300mm |

| X Axis | ||

| 3 | Wheel spindle type | Hydrostatic suspension motorized spindle |

| 4 | Wheel spindle cooling type | Oil cooling |

| 5 | Maximum speed of grinding wheel spindle | 3500rpm |

| 6 | Radial runout of the conical surface of the front end of the grinding wheel spindle | 1μm |

| 7 | Axial movement of grinding wheel spindle | 1μm |

| 8 | Axial stiffness of grinding wheel spindle | ≥150 N/μm |

| 9 | Radial stiffness of grinding wheel spindle | ≥200 N/μm |

| 10 | Eccentric shaft grinding wheel size (OD×width×ID) | 400*55.5*180 |

| 11 | Thrust surface grinding wheel size (OD × width × ID) | 250*37*160mm |

| 12 | X axis maximum stroke | 430mm |

| 13 | X axis linear motor maximum thrust | 4620N |

| 14 | X axis linear motor acceleration | ≤0.2G |

| 15 | X-axis linear motor cooling method | Oil cooling |

| 16 | X-axis guide sliding mechanism | TSK/PMI high quality rail |

| 17 | Minimum resolution of X axis grating ruler | 0.1μm |

| 18 | X axis feed positioning accuracy | 1.5μm |

| 19 | X axis feed repeat positioning accuracy | 1.5μm |

| Z Axis | ||

| 20 | Z axis spindle type | Ultra-precision motorized spindle with built-in encoder |

| 21 | Z-axis spindle cooling method | Oil cooling |

| 22 | Z axis spindle speed | 4500rpm |

| 23 | Z axis spindle coding type | Renishaw encoder

RESA30USA115B RA26BAA115B30A |

| 24 | Z axis balance level | G1 |

| 25 | Z-axis nose end face conical runout | 0.001mm |

| 26 | Z-axis spindle front end cone runout | 1μm |

| 27 | Z-axis spindle front end face beating | 1μm |

| 28 | Z axis spindle rear end outer circle runout | 0.005mm |

| 29 | Z-axis spindle rear end face beating | 0.002mm |

| 30 | Z axis maximum stroke | 380mm |

| 31 | Z axis servo motor power | 1.8KW |

| 32 | Z axis servo motor maximum speed | 3000rpm |

| 33 | Z axis maximum feed rate | 15m/min |

| 34 | Z axis feed positioning accuracy | 2μm |

| 35 | Z axis feed repeat positioning accuracy | 2μm |

| 36 | Rated speed of sanding spindle | 8000rpm |

| 37 | Sand repairing spindle cooling method | Water cooling |

| 38 | Sand repairing spindle power | 1.2Kw |

| 39 | Minimum feed of hand wheel | 0.001mm |

| Lathe Electric Parts | ||

| 40 | Standard 3-phase power supply | 380V 3ph 50-60Hz |

| 41 | Control circuit voltage | 110vAC/24vDC. |

| 42 | Input voltage deviation range | ﹢/-10% |

| 43 | Full load power consumption (host) | 45KW |

| Pneumatic Supply | ||

| 44 | Input air pressure | 5.5bar |

| 45 | Request flow | l/min |

| 46 | Air source standard | 8573-1:2001 |

| Environmental Parameter | ||

| 47 | Standard machine noise | <75dB(A) |

| 48 | Ambient temperature | 0-40℃ |

| 49 | Environment humidity | ≤75% |

| Others | ||

| 50 | CNC system and display | Lynuc System with 10.4 Inch LCD Touch screen |

| 51 | Net weight of oil cooler | 67Kg |

| 52 | The size of the machine tool (L* W * H) | 2635*1855*1760 mm |

| 53 | The size of the machine and its accessories (L×W×H) | 3000*1920*1760 mm |

| 54 | Net weight | 6000KG |

Resources & Downloads:

J2 Air conditioner refrigerator compressor crankshaft grinder Product Introduction :

Product features :

1. The J2 series of high-precision follow-up grinders are the best in today’s grinder products in terms of design concept or manufacturing technology.

2. Stable and reliable-super rigid structure excellent precision performance

The machine tool has been tested under the most severe environments and conditions, and has outstanding accuracy retention, which is suitable for requirements from single-piece to mass production.

3. Outstanding performance-excellent performance for processing special-shaped parts

High precision, high rigidity, and high efficiency are the basic characteristics of this grinder, achieving a perfect combination of performance and efficiency.

Due to the excellent performance of the machine tool and the excellent flexible design, it can be widely used in various industries such as aviation, medical, hydraulic, mold, high-end automobile manufacturing, core parts of robot reducer, core parts of air conditioner and refrigerator compressor.

4.Easy to operate-easy to use operating system

The latest generation of user-friendly graphical programming software developed by LYNUC MOTION has simple and fast settings and intuitive user interface. It does not require the operator to input complex codes and subroutines. The operation is simple and easy to learn, making programming and setting faster. The user experience and operating experience are excellent.

Standard Equipment

1. Standard grinding fluid supply system

2. 1 external grinding wheel

3. Thrust surface grinding wheel 1

4. Roller sand repairing device

5. Standard grinding and dressing cycle

6. Spindle oil cooling system

7. Standard manual toolbox

8. Linear motor and headstock spindle water cooling system

9. Lubricants added for the first time

10. Operation programming maintenance manual 1 set

Optional Equipment :

1. Truss manipulator

2. Automatic loading and unloading mechanism

3. External alignment device for eccentric circular machine

4. Customized fixture for workpiece clamping

5. Magnet + paper tape integrated filter device

6. Oil mist collector

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life