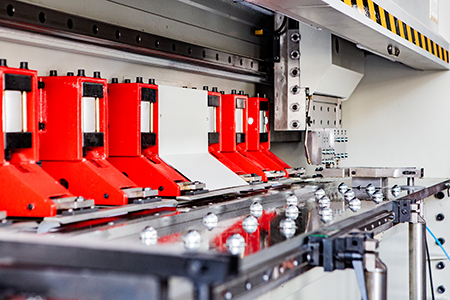

GCL Series gantry high-speed CNC grooving machine(touch screen upgrade)

Max cutting width : 1250mm

Max cutting thickness : 0.5-4mm

Max cutting distance : 8mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model | Max cutting width(mm) | Max cutting length(mm) | Max cutting thickness(mm) | Max cutting distance(mm) | Cutting speed(m/min) | Head resolution(up and down)(mm) | Positioningaccuracy(mm) | Main motor power(KW) | Hydraulic system working pressure(Mpa) | Machine outline size Length×Wdth× Height(mm) | Machine weight(T) |

| 1250×2500 | 1250 | 2500 | 0.5-4 | 8 | 60 | 0.001 | ±0.01 | 4.5 | 6-8 | 4500×2200×1680 | 7 |

| 1250×3200 | 1250 | 3200 | 0.5-4 | 8 | 60 | 0.001 | ±0.01 | 4.5 | 6-8 | 5200×2200×1680 | 7.5 |

| 1250×4000 | 1250 | 4000 | 0.5-4 | 8 | 60 | 0.001 | ±0.01 | 4.5 | 6-8 | 6000×2200×1680 | 8 |

| 1250×5000 | 1250 | 5000 | 0.5-4 | 8 | 60 | 0.001 | ±0.01 | 4.5 | 6-8 | 7000×2200×1680 | 9 |

| 1250×6000 | 1250 | 6000 | 0.5-4 | 8 | 60 | 0.001 | ±0.01 | 4.5 | 6-8 | 8000×2200×1680 | 11 |

The standard model is GCL type 1250×4000, the length and width of the machine can be customized, and the color of the machine can be customized.

Resources & Downloads:

GCL Series gantry high-speed CNC grooving machine(touch screen upgrade) Product Introduction :

Product performance and features:

·The latest touch screen operating system in Taiwan has the advantages of simple operation, high speed, high efficiency and highcost performance.

·Full servo control of machine movement, smooth and efficient cutting process, smooth cutting surface.

·The whole machine and sliding table have been heat treated, the overall steel is good, long-term use is not easy to deform.

·Four-axis CNC machine with precise positioning and wide processing range.

·Hydraulic pneumatic compaction, adjustable material, reliable compaction.

·with self-planer function, if the table is not even or defective after long-term use, self-planer function can be used to refresh the machine.

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life