APC Series Automatic Pallet Changer Horizontal Machine Center

HMC500APC / HMC630APC

HMC630SAPC / HMC800APC

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Model

Parameters |

Unit | HMC500APC | HMC630APC | HMC630SAPC | HMC800APC | |

| Processing

capacity |

Column travel ( X axis ) | mm | 800 | 1050 | 1050 | 1400 |

| Spindle travel (Y axis ) | mm | 750 | 900 | 750 | 950 | |

| Table travel ( Z axis ) | mm | 850 | 1000 | 900 | 1370 | |

| Distance from pallet surface to spindle center | mm | 100-850 | 100-1000 | 130-1030 | 100-1050 | |

| Distance from pallet center to spindle gauge plane | mm | 100-950 | 140-1160 | 0-750 | 150-1420 | |

| Processing

capacity |

X axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 |

| Y axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| Z axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| X/Y/Z axis cutting speed | mm/min | 20000 | 20000 | 10000 | 20000 | |

| Pallet | Table size | mm | 500*500 | 630×630 | 630x 700 | 800x 800 |

| Table no. | 2 | 2 | 2 | 2 | ||

| Table dividing type | 。 | 1( 0.001 ) | 1( 0.001 ) | 1( 0.001 ) | 1( 0.001 ) | |

| Table max loading weight | kg | 500 | 1200 | 950 | 2000 | |

| Tale T slot sie(N0,Width Distance) | mm | 14x5x 100 | 18x5x125 | 5x18x125 | 22x5x 160 | |

| Change time | sec | 15 | 16 | 20 | 18 | |

| Pallet | Spindle taper | ISO50 | ISO50 | ISO50 | ISO50 | |

| Spindle motor | kW | 11/15 | 15/18.5 | 15/18.5 | 18.5/22 | |

| Spindle speed | rpm | 20-6000 | 20-6000 | 20-6000 | 20-6000 | |

| Spindle max torquel(continuous/30min) | Nm | 140/191 | 249/307 | 249/307 | 520/619 | |

| Pull-stud | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | ||

| Accuracy | X/ Y/Z positioning accuracy | mm | 0.01 | 0.01 | 0.018 | 0.01 |

| X/Y/ Z repeated accuracy | mm | 0.006 | 0.008 | 0.01 | 0.008 | |

| B positioning accuracy | “ | ±4(±15) | ±4(+15) | ±15 | ±4(±15) | |

| B repeated accuracy | “ | ±1(±6) | ±1(±6) | ±4 | ±1(±6) | |

| ATC | Capacity | T | 40/60 | 40/60 | 32/40 | 40/60 |

| Max tool diameter | mm | Φ125/250 | Φ125/250 | Φ125/250 | Φ125/250 | |

| Max tool length | mm | 400 | 400 | 300 | 400 | |

| Max tool weight | kg | 25 | 25 | 18 | 25 | |

| Change time | sec | 3.5 | 3.5 | 4.5 | 3.5 | |

| Others | Total power | kw | 40 | 50 | 45 | 50 |

| Machine overall size(L*W*H) | mm | 6700x4200x3350 | 7600x4200x3650 | 6500x4100x3450 | 8400x 5000×3850 | |

| Machine weight | kg | 16000 | 22000 | 16000 | 26000 | |

Resources & Downloads:

APC Series Automatic Pallet Changer Horizontal Machine Center Product Introduction :

Product Features:

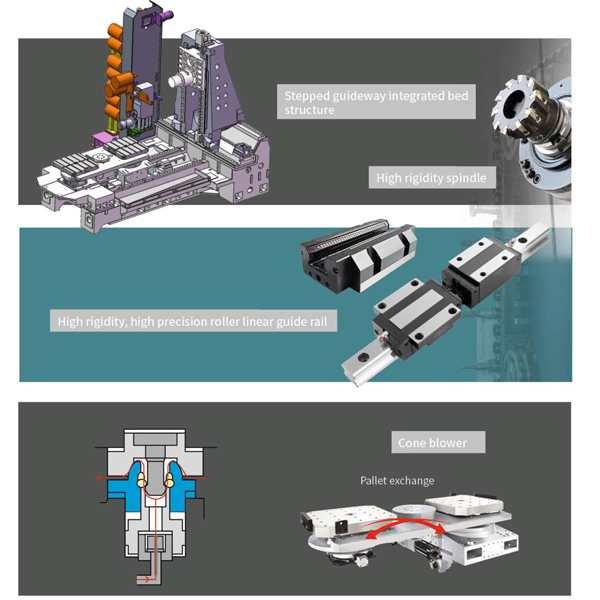

HMC series is a horizontal machining center designed and developed by the company on the basis of absorbing advanced machine tool design concepts at home and abroad.

This machine adopts T type bed structure design, adopts high rigid roller linear guideway, the guide way span is large, the machine overall rigidity is good, the bearing capacity is strong; Equipped with a rotary double exchange table, the exchange time is short, the table exchange positioning accuracy is high; Machine in processing parts at the same time can carry out the next spare parts of the damping, saving the damping time, improve the work efficiency;

The machine is especially suitable for batch processing of large and medium-sized box polyhedron parts. It can complete milling, boring, drilling, tapping and other processes in one time,greatly improving the processing eficiency.

Product Description :

| Number | Standard Equipment | Number | Optional Equipment |

| 1 | 24 tool ATC | 1 | 32 Arm chian type ATC |

| 2 | Spindle air curtain dust control system | 2 | 40 Arm chian type ATC |

| 3 | Workpiece cooling system | 3 | Central outlet of spindle (equipped with high pressure cooling device) |

| 4 | Equal division CNC rotary table | 4 | ZF gearbox drive |

| 5 | Automatic lubrication system | 5 | Spindle oil cooling device |

| 6 | Spiral chip removal device | 6 | Arbitrary indexing CNC rotary table |

| 7 | Chain-plate type chip lifter | 7 | Scraper lift chip remover |

| 8 | Integral shield | 8 | 3 axis linear scale |

| 9 | The toolkit | 9 | Tool detection device |

| 10 | Anchor bolt and pad iron | 10 | Workpiece detection device |

| 11 | Door opening protection (door protection) | ||

| 12 | Portable chip air gun | ||

| 13 | Machine cleaning water tank | ||

| 14 | Simple oil and water separator |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life