HY-300NC Fully Automatic High Speed Circular Saw Machine

Round bar●:150 ~ 300 mm

Square bar▓:150 ~ 220 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Cutting capacity | |

| Round bar ● | 150 ~ 300 mm |

| Square bar ▓ | 150 ~ 220 mm |

| Round tube ○ | 150 ~ 300mm Wall thickness ≥ pipe outer diameter * 10% (∅150*10%=15) |

| Square tube □ | 150 ~ 220mm |

| Machine head spindle | |

| Applicable to TCT tungsten carbide circular saw blade | Ø960 x 4.2 mm |

| Saw blade rotation number | 20 ~ 50 rpm / Variable speed |

| Saw blade debris remover | Round wire brush |

| motor | |

| Spindle drive motor | 55kw |

| AC servo motor_feed mechanism | 7.0kw |

| AC servo motor_delivery mechanism | 5.0kw |

| Hydraulic drive motor | 10HP / 4p |

| Hydraulic device | |

| Hydraulic drive pressure | 85 kg/cm2(8.5 MP a) |

| Hydraulic tank capacity | 150 liters |

| Air pressure device | |

| Working air pressure | 4 ~ 6 kg/cm2(55 ~ 85 psi) |

| Fixed-size feeding (GFC) mechanism | |

| End cutting length | 10~99mm |

| Residual length | 130+a (α is the length of a workpiece) |

| Feeding length | 800mm (single) |

| other | |

| Weight / main machine + rack | 15500KGS |

Resources & Downloads:

HY-300NC Fully Automatic High Speed Circular Saw Machine Product Introduction :

This equipment is mainly composed of machine tool bed, power head, feeding system, feeding device, clamping device, material dividing device, hydraulic system, electrical system, tool lubrication system, automatic lubrication system, automatic chip removal system, automatic loading system, etc.

1.Machine tool body

The bed is a key component of machine tool equipment. It is made of high-strength HT350 and is integrally cast. It has the characteristics of high strength, good rigidity, impact resistance, small deformation, and outstanding shock absorption performance. A well-structured bed can significantly improve the overall rigidity of the machine tool as well as the sawing stability and reliability.

2.Feed system

The servo motor + high-precision ball screw drives the power head to feed horizontally and forcefully, and the clamped workpiece can be cut off quickly and with high precision. This method is the current internationally advanced machine tool feeding sawing method, which can more effectively ensure the stability, reliability and continuity of the sawing process.

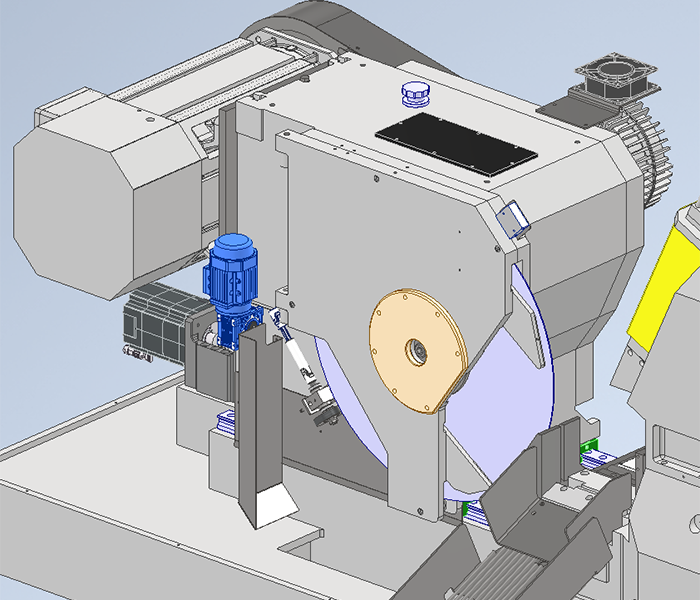

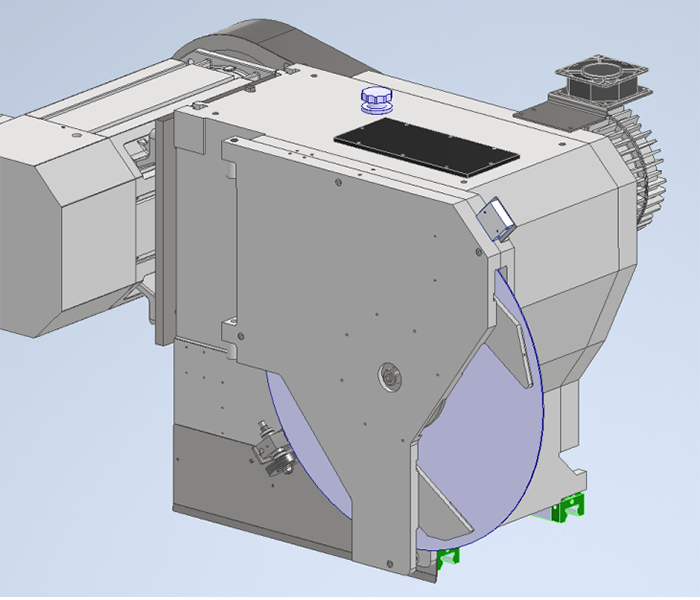

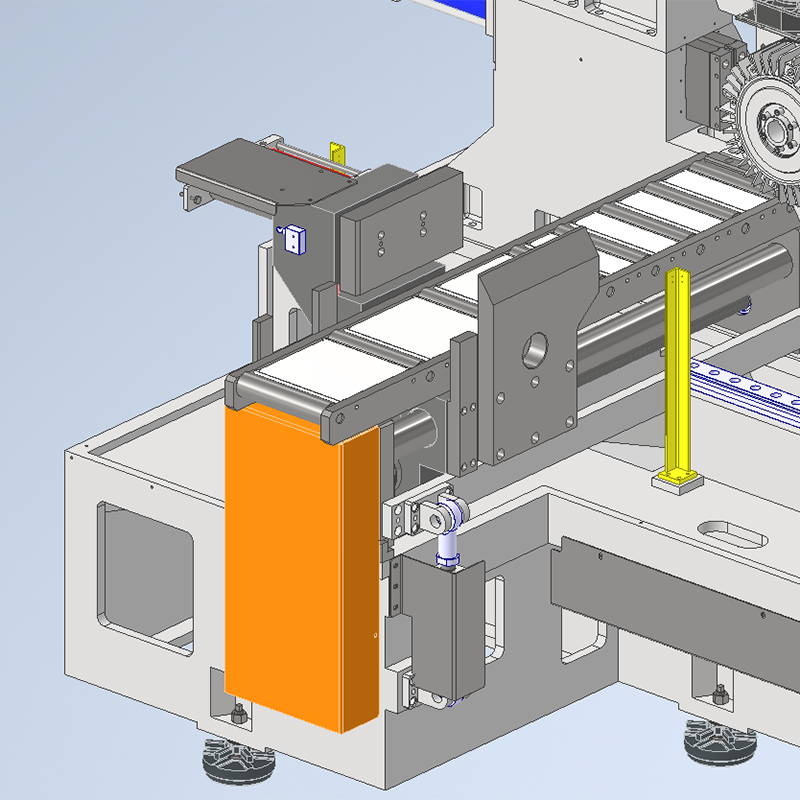

3.Power head

The power head is mainly composed of gearbox, pulley, spindle motor, magnetic powder brake, etc. The gearbox is cast with high-strength ductile iron QT450-10, and the high-precision ground forming gear adopts hardened bevel gear multi-stage transmission design, with high precision and smooth transmission. The magnetic powder brake is combined with the uniquely designed gear backlash elimination mechanism to achieve one-way zero-gap transmission, which greatly improves the service life of the tool. The gearbox bearings are all high-precision bearings of brands such as NSK, IKO, and SKF. The gearbox runs smoothly, has high transmission efficiency, high rigidity and high precision.

Using the spindle servo motor to drive the gearbox can achieve stepless speed change of the spindle, and the heat loss of large-scale speed regulation is small, and it can reach the ability of 30 minutes of continuous overload without damaging the motor.

The power head is guided by high-rigidity and high-precision roller-type linear guides, which can ensure feed accuracy and rigidity, and is a strong guarantee for cutting accuracy and life.

| Power head | Power head |

|

|

4.Clamping device (main clamp)

The main clamp is fixed on the bed and consists of a set of horizontal clamps and a set of vertical clamps installed on the clamp seat. It can provide horizontal and vertical clamping force to the workpiece during the cutting process. The clamping power is provided by the hydraulic cylinder, and the two sets of clamps can act independently.

|

|

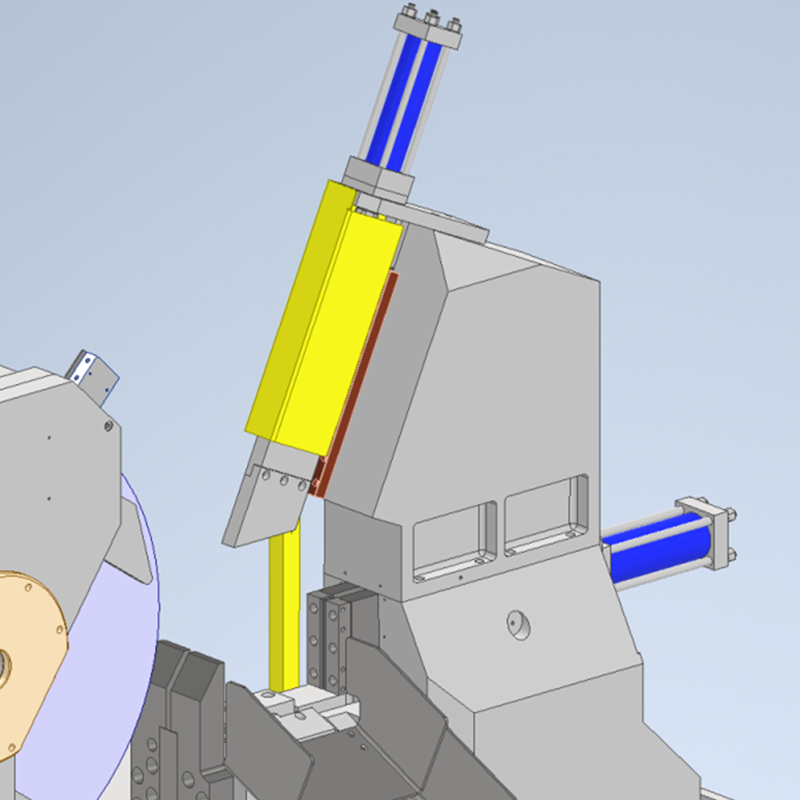

5.Feeding mechanism

The feeding mechanism adopts a large-diameter, high-load double guide rod structure, and uses a high-power AC servo motor to directly drive the grinding-grade ball screw to perform linear reciprocating motion, with good rigidity and high precision. The clamping mechanism is powered by a hydraulic cylinder, with sufficient clamping force and high clamping precision. The clamp of the feeding mechanism can swing up and down during the forward and backward feeding process, which can prevent the material from scratching and interfering with the clamping device, extend the service life of the clamp, and improve the cutting accuracy.

|

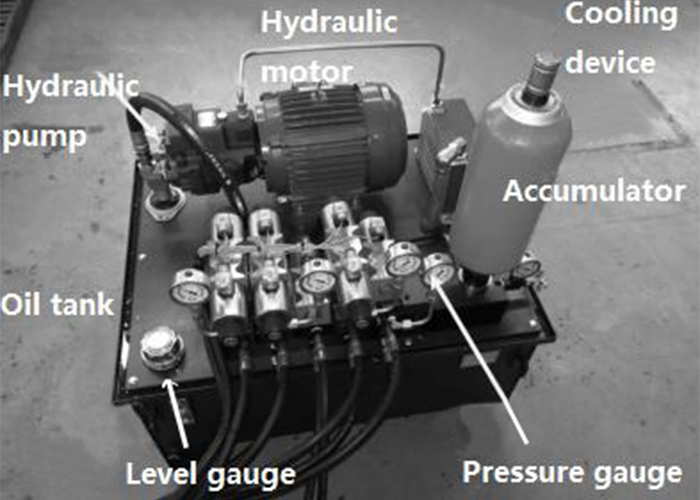

6.Hydraulic system

The hydraulic system adopts an external independent structure for easy maintenance. It adopts integrated installation of superimposed valves, which is compact, safe and reliable.

| External independent station | Pressure Switch |

|

|

7.Electrical system

The electrical system is mainly composed of a cantilever operating table, an electrical cabinet, a logic controller (PLC), a servo motor and driver, a switching power supply, a servo transformer, an intermediate relay, a contactor and thermal overload, a tension controller, low-voltage components, and a constant temperature air conditioner in an electrical cabinet.

It adopts a true color human-machine interface, multi-level authority management, and convenient parameter setting. There are two modes of control: manual and automatic. In manual mode, all functional components can be operated, and function conversion and start and stop operations are convenient.

8.Tool cooling and lubrication system

The machine tool is equipped with a standard dry tool lubrication system, which can provide regular and quantitative forced lubrication. It uses vegetable cutting oil, which is economical and environmentally friendly.

9.Automatic lubrication system

The automatic lubrication system can use thin oil to force lubricate the screw rod, guide rail and movable joints at a regular and quantitative time, which can extend the service life of the equipment.

( See the below pictures for the Spray cooling system for reference)

| Automatic lubrication metering dispenser | Automatic Lubrication System |

|

|

10.Automatic chip removal system

This equipment is equipped with a chain plate chip conveyor as standard, with two chip removal modes to choose from: continuous and intermittent operation, with forward and reverse control. The chip removal system is equipped with a chip collection trolley with rollers.

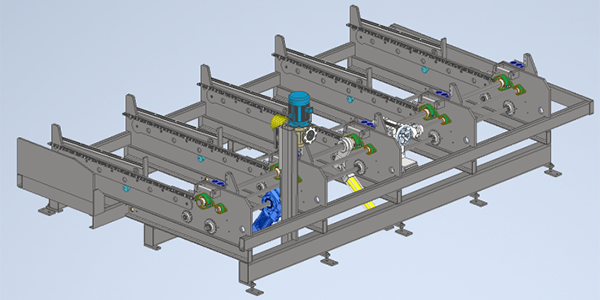

11.Automatic feeding system

The automatic feeding system consists of a material rack, a conveying mechanism, a material separation mechanism, an adjustment mechanism, a driving mechanism, etc., and is centrally controlled by the host. The conveying mechanism uses a reduction motor as the power to drive the chain to drive the workpiece, and the material separation mechanism uses a hydraulic cylinder as the power to sort the materials. After the size of the workpiece is manually set through the adjustment mechanism, the feeding system can complete the automatic sorting and feeding action under the control of the host.

The material rack can bear 1.5 tons per meter, and the overall load-bearing capacity is greater than 10 tons.

| Automatic feeding system | Standard free automatic chip removal system |

|

|

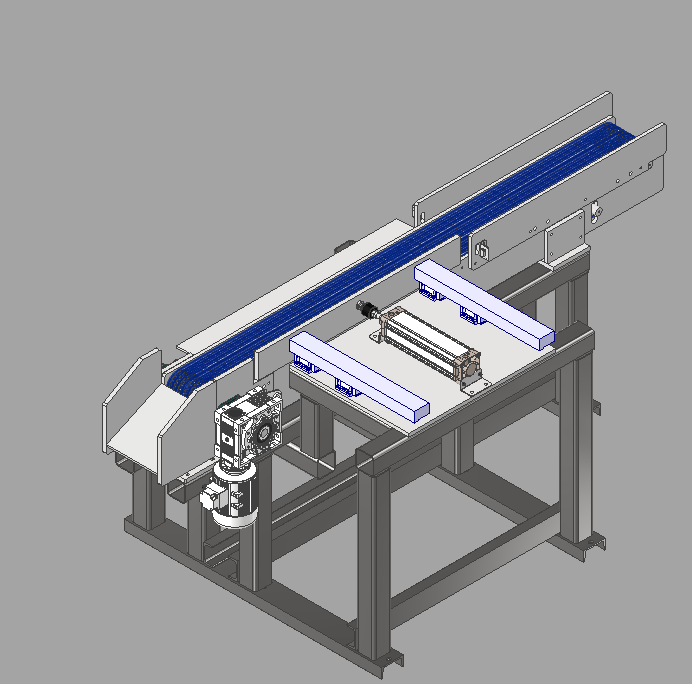

12.Discharging conveyor (optional)

The discharging conveyor mechanism consists of a reduction motor, a conveyor belt, a feeding wheel, a frame and a material separation mechanism. The material separation power comes from the cylinder. The cut material moves outward under the drive of the conveyor belt. When the material head reaches the fixed position, it is detected by the photoelectric switch and can be pushed out to the side or not. The material will continue to move outward until it leaves the conveyor.

|

13.Other configuration instructions

1) The working area is equipped with waterproof and dustproof LED lighting;

2) The machine tool is equipped with a three-color warning light, which indicates green when the program is running, orange when the work cycle is completed, and red when a fault alarm occurs.

| LED Light for night-shift working | Three-color warning lights show status |

|

|

Main Parts &Spare Parts

| NO. | Spare Parts Description | Brand |

| 1 | Touch screen | Siemens of Germany |

| 2 | Logic controller | Siemens of Germany |

| 3 | Feed servo motor | Siemens of Germany |

| 4 | Feed servo motor | Siemens of Germany |

| 5 | Contactor | Siemens of Germany |

| 6 | Thermal relay | Siemens of Germany |

| 7 | Solenoid valve | Taiwan Oil Research Institute |

| 8 | Oil pump | Taiwan Oil Research Institute |

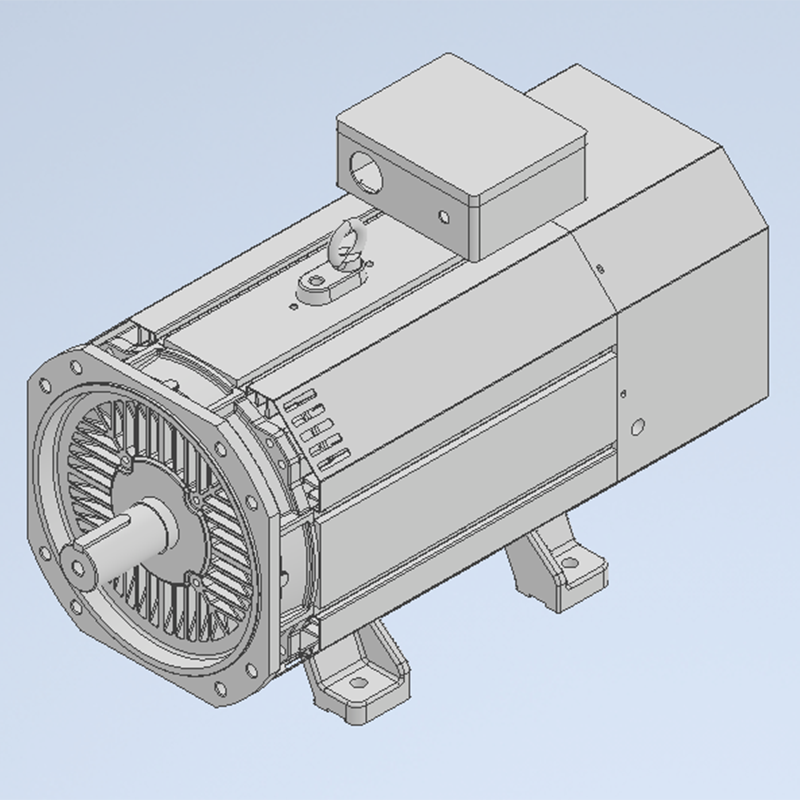

| 9 | Spindle servo motor | Shanghai Meishike |

| 10 | Tool lubrication system | Taiwan Suncooler |

| 11 | Automatic lubrication system | Taiwan ISHAN |

| 12 | Main seals | Taiwan NAK |

| 13 | Pneumatic components | Taiwan AirTac |

| 14 | Hydraulic components | Taiwan Jiagang |

| 15 | Ball screw | Taiwan Hiwin |

| 16 | Linear guide | Taiwan Hiwin |

| 17 | Toothed V-belt | Gates of the United States |

The accessories in the configuration list allow the manufacturer to change the accessory brand to a higher level according to the material supply.

Users can purchase other brand accessories according to their needs.

Spare Parts

| NO. | Spare parts name | QTY | UNIT |

| 1 | Wire wheel | 2 | PCS |

List of free Special tools

| NO., | Special tools name | QTY | UNIT |

| 1 | Allen wrench | 1 | Set |

| 2 | screwdriver | 2 | Pcs |

| 3 | adjustable wrench | 1 | Pcs |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life