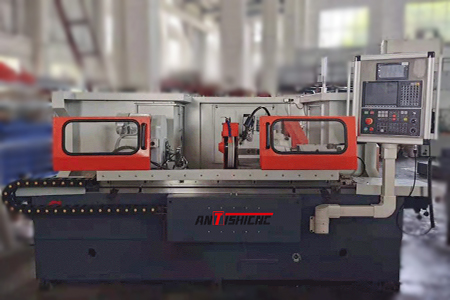

MK1332x1000 CNC Cylindrical OD Grinder

Maximum grinding length:1000mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Technical parameter | MK1332/1000 |

| Grinding diameter range | Ф8~Ф320(mm) |

| Maximum grinding length | 1000(mm) |

| Maximum working weight | 150(kg) |

| Center height | 180(mm) |

| Maximum table rotation angle | -3°~+5° |

| Grinding wheel frame rotation angle | ±30° |

| Head and tail frame top taper: | Mohs 4# |

| Tail frame sleeve movement | 30mm |

| Grinding wheel frame maximum stroke | 320mm |

| Worktable maximum stroke | 1050mm |

| Grinding wheel speed | 0-1460r/min(Frequency conversion stepless speed regulation) |

| Grinding wheel specifications | Φ600mm×75×Φ305mm |

| Workpiece head frame motor power | 1.5kw |

| Grinding wheel head frame motor power | 11kw |

| Oil pump motor power | 0.75kw |

| X-axis private service motor torque | 7um |

| Z-axis private service motor torque | 10um |

| Water tank capacity | 150L |

| Grinding wheel frame (X-axis) minimum resolution: | 0.001mm |

| Worktable (Z-axis) minimum resolution | 0.001mm |

| Grinding wheel frame (X-axis) positioning accuracy | 0.01mm |

| Grinding wheel frame (X-axis) repeat positioning accuracy: | 0.003mm |

| Grinding wheel frame (X-axis) reverse clearance | ≤ 0.005mm |

| Worktable (Z-axis) positioning accuracy | 0.01mm |

| Worktable (Z-axis) repeat positioning accuracy | 0.003mm |

| Worktable (Z-axis) reverse clearance | ≤0.005mm |

Resources & Downloads:

MK1332x1000 CNC Cylindrical OD Grinder Product Introduction :

Product Details

1.The machine bed is cast as a whole, with stable structure and strong rigidity.

2.The guide rail of the machine bed worktable is a flat-V guide rail with low resistance and smooth movement.

3.The machine tool adopts a layout form in which the headstock is placed on the worktable and reciprocates with the worktable, and the grinding wheel frame is placed on the feed slide for longitudinal feeding movement.

4.The grinding wheel frame feed and the reciprocating movement of the worktable are driven by a servo motor through a gap-free elastic coupling to drive a high-precision ball screw for movement, which has the characteristics of low resistance and high precision.

5.The grinding wheel frame feed guide rail adopts a cross-cross roller steel guide rail, which has the characteristics of strong rigidity and low resistance.

6.The main shaft of the grinding wheel frame of the machine tool adopts a sleeve structure, which has the characteristics of strong rigidity and large bearing capacity. The inverter drives the variable frequency motor to realize variable frequency stepless speed regulation.

7.The workpiece head frame motor adopts an AC frequency conversion device to realize stepless speed regulation. The head frame motor drives the workpiece spindle to rotate through a pulley, and the speed is controlled by the AC inverter and connected to the system.

8.The grinding wheel correction device is front-mounted, and the diamond pen realizes the dressing of the outer circle of the grinding wheel through the linkage of the X and Z axes.

9.The machine tool has a fully automatic function, and it can realize automatic feeding, automatic dressing, and automatic compensation during grinding.

10.The grinding cooling system of the machine tool is equipped with a magnetic separator to ensure the full separation of grinding dust and coolant.

11.The machine tool is a semi-enclosed two-axis CNC cylindrical grinder.

12.Electrical system

12.1 The control system of this machine tool adopts the Huazhong 808DG CNC system, and uses an LCD color display that can be switched between English and Chinese. It can realize the linkage of the X/Z axis, the grinding wheel interpolation dressing, automatic detection of CNC system faults, fault alarms, and alarms with history records, and provides pre-installed typical grinding programs; control and display process parameters, convenient and fast input of size values, grinding wheel values, and grinding parameters, simple settings, with a variety of cycle program call functions, and grinding wheel life management functions.

12.2 The machine tool is equipped with a handheld unit, which can select the axis system and magnification, convenient for adjustment and part tool setting, especially suitable for multi-variety, medium-volume production;

12.3 The machine tool electric box is an independent electric box, which is placed on the right rear side of the bed, beautiful and generous. The control box is placed in front of the bed and can be rotated at a certain angle. It is convenient to operate. The internal wiring is standardized, the line number is clear, and all PLC output points must be transferred through the intermediate relay. The electric box is equipped with a special heat exchanger. It has overload protection, overtravel protection and other functions. Electrical components are of the French Schneider brand.

12.4 A warning sign with equipment operating procedures is posted in a conspicuous position (using waterproof material), the human-machine environment is good, and it is equipped with a three-color warning light.

Standard Equipment&Optional Equipment

| Name | Model | Quantity | Origin |

| Magnetic separator | CF-02 | 1set | ANTISHICNC |

| Feed ball screw | 1set | Nanjing Technology | |

| Worktable reciprocating ball screw | 1set | Nanjing Technology | |

| CNC system | Huazhong 808DG | 1set | Wuhan |

| Grinding wheel frame frequency conversion motor | 1set | Jiangsu Guanshun | |

| Workpiece head frame frequency conversion motor | 1set | Jiangsu Guanshun | |

| Grinding wheel frame frequency converter | 1set | Wuxi Morikawa | |

| Workpiece head frame frequency converter | 1set | Wuxi Morikawa | |

| Screw lubrication device | 1set | Changzhou Fuheng | |

| Handheld unit | 1set | Wuxi Kejie | |

| Electrical box heat exchanger | 1set | Wuxi Condi | |

| Screw lubrication pump | 1set | Changzhou | |

| Electrical components | Complete set | France Schneider | |

| Inductive proximity switch | Complete set | Sweden Kerry | |

| Feed steel guide rail | Complete set | Nanjing Technology | |

| Bearing | Complete set | Japan NSK |

Special accessories (Optional)

Outside diameter measuring instrument

End face measuring instrument

Fully enclosed housing

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life