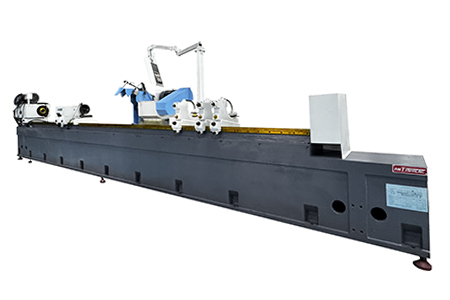

MKZW1363x70 Wheel Head Moving CNC Cylindrical Grinding Machine

Max. grinding outer diameter range: 630mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

Machine limit position dimensions

| Machine size | Length(mm) | Width(mm) | Height(mm) |

| Ø630×7000 | 14500 | 3500 | 2500 |

Main Specifications

| Grinding outer diameter range (mm)

Center height (mm) |

Max. | 630 |

| Mini | 30 | |

| Headstock top taper | 370 | |

| Tailstock top taper | Metric 80# | |

| Top distance (mm) | Metric 80# | |

| Maximum grinding outer diameter length (mm) | 7000 | |

| Maximum grinding length when dressing the grinding wheel with the tailstock dresser (mm) | 7000 | |

| Maximum workpiece weight for top grinding (Kg) | 6750 | |

| Maximum workpiece weight for support grinding (Kg) | 1500 | |

| Grinding outer diameter range (mm) | 3000 | |

| Tailstock top sleeve travel (mm) | 70 | |

Headstock

| Possibility of headstock spindle rotation | Non-rotatable |

| Possibility of headstock body shell rotation | Non-rotatable |

| Headstock dial speed (r/min) | 10~100 |

| Headstock spindle front taper hole | Metric 80# |

Carriage

| Max. longitudinal movement (mm) | 7000 |

Grinding wheel stand

| Horizontal stroke (mm) | 320 | |

| Grinding wheel linear speed (m/s) | ≤35 | |

| Grinding wheel size (mm) | Max. | Ø750×75×Ø305 |

| Wear to | Ø550×75×Ø305 | |

Hydraulic system

| Oil pump flow (L/min) | 25 |

| Main system adjustment pressure (Mpa) | 1.2~1.4 |

| Auxiliary system adjustment pressure (Mpa) | 0.5~0.7 |

| Lubrication system adjustment pressure (Mpa) | 0.4~0.6 |

Cooling system

| Cooling pump rated flow (L/min) | 50 |

Accuracy

| Roundness mm | 0.005 |

| Diameter consistency mm | 0.020/1000 |

| Surface roughness Ra (μm) | 0.4 |

Electrical system

Grinding wheel motor power: 22KW;

Head-stock motor power: 15KW;

Total machine power: 55KW;

HNC CNC system, other systems can also be configured according to user requirements, like FANUC ect

Resources & Downloads:

MKZW1363x70 Wheel Head Moving CNC Cylindrical Grinding Machine Product Introduction :

Main Application

1. This machine tool is suitable for grinding the outer cylindrical surface of slender shaft parts such as lead screws, and is used in various production occasions. The feature of this machine tool is the integrated bed structure with a movable grinding wheel frame.

2. The overall structure of this machine tool adopts a movable grinding wheel frame layout, and the main component structures include: headstock, tailstock, grinding wheel frame, carriage, and horizontal feed mechanism.

3. The longitudinal movement of the grinding wheel frame of this machine tool is achieved by a servo motor driving a high-precision rack through a reduction gearbox; the horizontal feed of the grinding wheel frame is achieved by a servo motor driving a ball screw.

4. The workpiece, grinding wheel, oil pump and cooling pump are driven by independent motors respectively.

Features

Headstock

1. The headstock of this machine is box-shaped and fixed on the workbench by two M30 bolts. Due to the use of a dead center device, the rigidity is good, which improves the grinding quality.

2. The headstock can rotate the hexagonal head according to actual needs, and move it to the desired position along the workbench longitudinally through the gear rack.

3. The tapered hole in the front of the headstock spindle can be installed with a metric 80# center. The variable frequency motor located on the top of the body shell can change the motor speed through the inverter so that the headstock spindle can obtain a speed of 10 to 100rpm. Therefore, when grinding the workpiece, you can choose the appropriate spindle speed. When the workpiece is small, a higher spindle speed should be selected; when the workpiece is large and heavy, a lower speed should be selected, so that better machine tool grinding accuracy can be obtained.

Tailstock

1. The tailstock of this machine is fastened to the right side of the workbench by two M30 bolts. When grinding workpieces of different lengths, the hexagonal head can be rotated and moved to the desired position along the workbench longitudinally through the gear rack.

2. Turn the hand wheel and the sleeve can be moved forward and backward in the body shell through the screw. The metric 80# tip is configured in the tapered hole in the front of the sleeve. A set of disc springs are placed at the rear of the screw to compensate for the thermal expansion caused by grinding the workpiece.

3. There is a dresser on the left side of the tailstock. When dressing the grinding wheel, the dresser can be moved forward and backward as needed. When using the dresser to dress the grinding wheel, the workpiece does not need to be removed, which is convenient for operation. However, in special cases such as when the workpiece is long or the workpiece diameter is large, the dresser installed on the workbench should still be used.

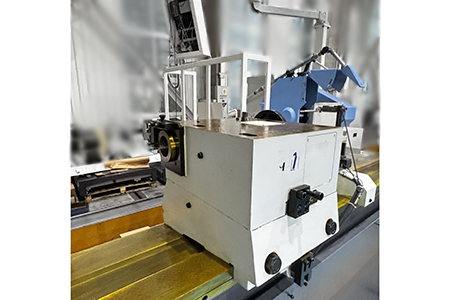

Grinding wheel frame

1. The grinding wheel frame of this machine tool consists of an upper and lower part. Its internal spindle support adopts a dynamic and static pressure bearing structure. The dynamic and static pressure bearing has axial and radial support functions. When the external static pressure lubrication pressure oil is injected, the spindle floats. The AC asynchronous motor drives the spindle to rotate through the belt and pulley to generate a dynamic pressure rigid oil film, thereby supporting the rotation of the spindle.

2. The transverse guide adopts a flat-V structure, and the guide surface is plastic-coated. Its friction coefficient is small, which can more effectively maintain the original accuracy of the guide and improve the life of the guide pair. The transverse guide adopts open throttling static pressure lubrication.

Longitudinal feed

The longitudinal movement of the grinding wheel frame of this machine tool is achieved by the servo motor driving the high-precision gear rack through the reduction box.

Transverse feed mechanism

The transverse feed mechanism of the grinding wheel frame of this machine tool is located on the back of the bed. It is achieved by the servo motor driving the ball screw through the reduction mechanism.

Standard Configuration

| Name | Part No | Specifications | Quantity | Remark |

| Electric box | 1 Set | Installed on machine | ||

| Sediment coolant tank | 50L/min | 1 Set | ||

| Hydraulic station | 1 Set | |||

| Spindle hydraulic station | 1 Set | For grinding wheel head spindle | ||

| Measuring bridge | M1363×50-85-100 | 1 Pcs | ||

| Grinding wheel outer circle dresser | M1363*50-60 | 1 Set | Without diamond pen, installed on the workbench | |

| Open center frame | M1363*50-63 | Support diameter 30~200 | 2 Sets | |

| Open center frame | M1363*50-63/1 | Support diameter 200~350 | 2 Sets | |

| Machine pad iron | 1 Set | |||

| Chuck | MZW1380×80-85-001 | φ300~φ400 | 1 Set | |

| Clamp chuck | M1350×30-85-001 | Ø150~Ø300 | 1 Pcs | |

| M1350×30-85-002 | Ø75~Ø150 | 1 Pcs | ||

| Grinding wheel clamping flange | HJX37-100 | 1 Set | ||

| Top | M1363×50-85-300 | Metric 80# | 2 Pcs | |

| Hexagonal socket wrench | HS92-9 | 75 | 1 Pcs | For disassembling and installing grinding wheels |

| Grinding wheel remover head | HS79-1 | M135×2 | 1 Pcs | For disassembling and installing grinding wheels |

| Grinding wheel hanging rod | HS79-2 | 600 | 1 Pcs | For disassembling and installing grinding wheels |

| Balance shaft | HS79-3 | Ø100(1:5 Taper) | 1 Set | For balancing grinding wheels (including nuts and washers)) |

| Grinding wheel | P750×75×305

WA60K6V35 |

750×75×305 | 1 Pcs |

Note:

1. If there are special requirements for the grinding wheel, the user needs to provide the brand before signing the contract, and it will be confirmed by Party B, and the price needs to be calculated separately.

2.The standard configuration is a simple packaging with wooden bar support, and the wooden base packaging is a special package with PCs, and the price needs to be calculated separately.

Optional Configuration

| Name | Part No | Specifications | Quantity | Remark |

| Grinding wheel balance frame | HJX85-03 | 1Set | ||

| Grinding wheel end face dresser | HJX37-270A | 1Set | Without diamond pen, installed on the workbench | |

| Grinding wheel arc dresser | HJX36-270 | 1Set | Without diamond pen, installed on the workbench | |

| Magnetic separator coolant tank | 50L/min | 1Set | When optional, the standard coolant tank is cancelled | |

| Open center stand | HJX45-270 | Support diameter 25~200 | ||

| Open center stand | M1350×30-63/1 | Support diameter 200~350 | ||

| Closed center stand | HJX11-270 | Support diameter 25~200 | ||

| Outer diameter measuring instrument | Measurement range 25~290 | |||

| End face measuring instrument |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life