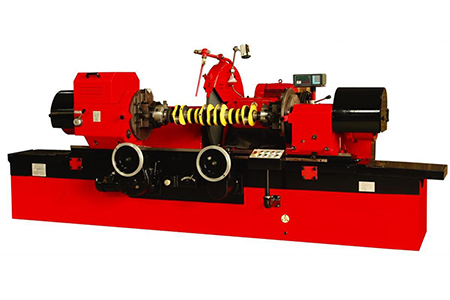

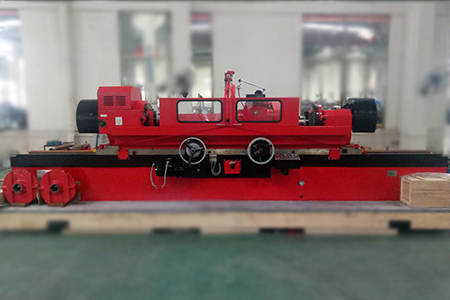

MQ8260B Series Crankshaft Grinding Machine

Max.work diameter*Max.length: φ580×2000mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | MQ8260Bx2000 | ||

| Max.work diameter*Max.length | φ580×2000mm | ||

| Max. workpiece rotation diameter | 580mm | ||

| Grinding diameter on center stand | Max.10mm, Mini. 30mm | ||

| Longitudinal grinding outer diameter | Max. 200mm, Mini.30mm | ||

| Crankshaft crank radius | Max.110mm, Mini. 0mm | ||

| Max.workpiece installation length | Chuck | 1700mm | |

| Between centers | 2000mm | ||

| Center height | 300mm | ||

| Headstock top taper | Mohs #5 | ||

| Tailstock top taper | Mohs #5 | ||

| Maximum workpiece weight | 120kg | ||

| Tailstock sleeve movement | 30mm | ||

| Grinding wheel dressing and compensation feed | Manual | ||

| Automatic cycle feed | Don’t have | ||

| Automatic cut-in feed | Don’t have | ||

| Possibility of headstock rotation | Possible | ||

| Possibility of body rotation | Impossible | ||

| Spindle speed | 50Hz | 25,50,100 r/min | |

| 60Hz | 30,60,120 r/min | ||

| Three-jaw chuck diameter MQ8260B | 200mm | ||

| Movement of the workbench per hand wheel rotation | 5mm | ||

| Max.longitudinal movement | Manual | 2000mm | |

| Motorized | 2000mm | ||

| Max. rotation angle of upper worktable | Clockwise 1°30′, counterclockwise 1°30′ | ||

| Grinding wheel size | Maximum 900*20~40*305mm | ||

| Wear volume 600×20~40×305mm | |||

| Spindle speed | 50HZ | 760 r/min | |

| 60HZ | 760 r/min | ||

| Max. movement (including rapid movement) | 300mm | ||

| Max. travel along the screw | 200mm | ||

| Rapid advance and retreat | 100mm | ||

| Adjustment between middle seats | Forward | 70mm | |

| Backward | 55mm | ||

| Amount of movement per turn of the horizontal feed handwheel | 1mm | ||

| Amount of movement per grid of the horizontal feed handwheel | 0.005mm | ||

| Radius of the repairable grinding wheel arc | 0-8mm | ||

| Main oil circuit adjustment pressure | 1-1.3 MPa | ||

| Lubricating oil circuit adjustment pressure | 0.1-0.3 MPa | ||

| Oil pump flow | 10 L/min | ||

| Note: MQ8260B/H is 11 mL/r | |||

| Oil pump pressure | 2.5 MPa | ||

| Note: MQ8260B/H is 6.3 MPa | |||

| Cooling pump type | AYB-50GC | ||

| Cooling pump flow | 50 L/min | ||

| Grinding wheel motor power | 7.5KW | ||

| Head frame motor power | 1.5KW | ||

| Oil pump motor power | 0.55KW | ||

| Cooling pump motor power | 0.2KW | ||

| Work table motor power | 0.75KW | ||

| Machine size – length*width *height | 4650*2100*1600mm | ||

| Net weight | 7000kg | ||

| Packaging size – length*width*height | 6000*2250*2000mm | ||

| Packaging gross weight | 8000kg | ||

Remark: MQ8260B is an upgraded version of MQ8260A. Now there is no A in the MQ8260 series, if you want to know more details, please contact with shanghai ANTISHICNC.

Resources & Downloads:

MQ8260B Series Crankshaft Grinding Machine Product Introduction :

Product description

MQ8260B & MQ8260B/6 series crankshaf are simple in construction, easy in operation and wide in application; suitable for grindingcrankshaft pins and joumals, lt can also be used as cylindrical grinder.The machine is controlled by mechanical, electric and hydraulic means; operated mainly by hand.Left right chucks are crisscross and adjustable.

Workpiece is held by centers or by chucks, driven by workhead motor, and feed by hand for grinding.The worktable consists of upper and lower parts, and upper part having the inclined worktable-surface at 10″( only for MQ8260B/6)Longitudinal worktable travel is realzed by manual-drive or motor-drive, with the motor dfive for jump displacement or adjustmentThe max. wheel, worktable, coolant pump and oll pump are driven by their individual motors.

Worktable and wheelhead have the hydraculic and electric interlocking mechanism, ensuring the safely even if misoperation whetheiin adlustment or in the process of grinding. The wheelhead is equipped with the reliable protective guard, the coolant guard and thebed ways guard is stainless steel. The wheel balancing stand adopt new static wheel balancing stand.

Features

1.The rapid advance and retreat of the grinding wheel frame is completed by hydraulic pressure.

2.The longitudinal movement of the workbench can be manual or mechanical. When it is mechanical, the workbench can only be moved in a jog and moved quickly to facilitate the grinding of the next journal.

3.The workpiece can be clamped by a three-jaw chuck, or the head and tail chucks can be removed and supported by the center.

Main Applications

MQ8260Bx2000 is a crankshaft grinder suitable for grinding crankshaft necks and main journals of engines in automobile, tractor and diesel engine repair shops, and can also be used for grinding general external circles.

Standard Equipment

| No | Part Name | Part No | Details | Q’ty. |

| 1 | Electric cabinet | HDQ01-14x8A | 1 pcs | |

| 2 | Coolant Tank | HJX71-50 | 50L/min | 1 set |

| 3 | Wheel dresser | MQ8260-60 | 1 set | |

| 4 | Steady rest | MQ8260-65 | 1 set | |

| 5 | Left chuck | MQ8260B-83 | 1 set | |

| 6 | Right chuck | MQ8260B-84 | 1 set | |

| 7 | Balancing weight | MQ8260-81A | 2 sets | |

| 8 | Driving dog | MQ8260-85-001 | 1 set | |

| 9 | Vertical aligning plate | MQ8260-85/ 1 | 1 set | |

| 10 | Horizontal aligning plate | MQ8260-85/2 | 1 set | |

| 11 | End-Face dresser | MQ8260-61 | 1 set | |

| 12 | Leveling wedge | HJX81-2 | Full sets | |

| 13 | Measuring bridge-board | MQ8260-85-106a | 1 pcs | |

| 14 | Hex. socket spanner | HS92-9 | 55 | 1 set |

| 15 | Wheel extractor | HS79-1 | M115x2 | 1 set |

| 16 | Wheel hook | HS79-2 | 600 | 1 pcs |

| 17 | Wheel balancing shaft | HS79-3 | 80 | 1 pcs |

| 18 | Hex. nut | HJ13-3 | B-M36x3LH | 1 pcs |

| 19 | Flange clamping washer | HJ59-1 | 36×86 | 1 pcs |

| 20 | Center | S77-7 | Morse#5 | 2 sets |

| 21 | Bolt | J21-1 | M16x50 | 1 pcs |

| 22 | Driving-rod arm | HC91-1 | 65 | 1 pcs |

| 23 | Driving rod | HC91-2 | M16x90 | 1 pcs |

| 24 | Spare paint | 1 tin | ||

| 25 | Liner | MQ8260-85-307 | 8 pcs | |

| 26 | V-belt | A-965 | 1 pcs | |

| 27 | A-940 | 2 pcs | ||

| 28 | A-1041 | 3 pcs | ||

| 29 | B-1397 | 5 pcs | ||

| 30 | Wheel flange | MQ8260-86 | 2 sets | |

| 31 | Coolant guard | MQ8260-76-500 | 1 pcs | |

| 32 | Splash guard | MQ8260-76-308 | 1 pcs | |

| 33 | Square-socket wrench | S92-3 | 17 | 1 set |

Optional accessories

| No | Name | Part No | Specifications |

| 1 | Wheel balancing stand | HJX35-1100 | Ø900~ Ø1100 |

| 2 | Suspension-type measuring instrument | MQ8240-42 | |

| 3 | Correcting device | MQ8260-85/3 |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life