QC11Y-8×6000 Hydraulic Guillotine Type Shearing Machine

Max. plate thickness:8mm

Max. plate width:6000mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Unit | QC11Y-8×6000 |

| Max. shearing plate thickness | mm | 8 |

| Max. shearing plate width | mm | 6000 |

| Sheared sheet tensile strength | N/mm2 | δb≤450 |

| Shear angle | ° | 1.5—2 |

| Number of travels | times/min | 8~15 |

| Throat depth | mm | 150 |

| Blade length | mm | 6100 |

| Workbench height from the ground | mm | 1050 |

| Back gauge range | mm | 20~800 |

| Main motor model | / | Y132M-6B5 |

| Main motor power | KW | 15 |

| Main motor speed | rpm | 1440 |

| Gear pump model | / | NB2-40GF |

| Gear pump flow | L/min | 80 |

| Gear pump pressure | Mpa | 31.5 |

| Equipment Size(L*W*H) | mm | 3750*1700*2500 |

Resources & Downloads:

QC11Y-8×6000 Hydraulic Guillotine Type Shearing Machine Product Introduction :

Product Details

The whole machine adopts an all-steel welded structure, and the welded parts such as wall panels, workbenches, and tool holders eliminate stress by vibration, and have good rigidity and stability.

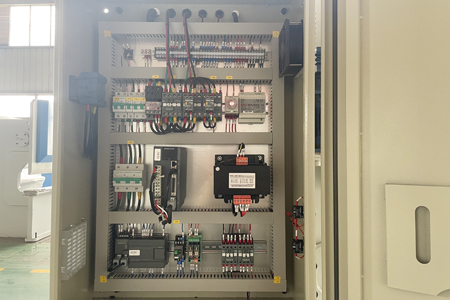

1. This machine is the latest generation hydraulic shearing machine. Advanced hydraulic integrated valve block is adopted. The structure is compact, the pipeline connection is reduced, and the reliability and easy maintenance of the system are improved.

2. Structural parts are derusted by shot blasting and sprayed with antirust paint;

3. The main parts of the machine tool, such as the machine frame, the upper tool rest, and the workbench, are finished by domestic famous brand CNC large-scale floor boring and milling machines, which ensures the geometric accuracy of the main machine.

4. The tandem oil cylinders make the oil cylinders synchronized when the machine tool is shearing, and the shearing angle can be adjusted.

5. The installation surface of the blade on the upper tool holder is a helical surface, which ensures the uniformity of the blade gap during the cutting process, and the quality of the cutting section is good. Supported by the sub-shaft, the upper knife holder swings up and down, and the eccentric mechanism quickly adjusts the blade gap to improve the cutting accuracy.

6. The return stroke of the accumulator is stable and rapid, which changes the structure of the traditional gas storage tank and prevents the leakage of nitrogen gas.

7. The upper and lower blades are rectangular, and the material is 6Crw2Si, which has good hardness and long service life.

8. The gap between the upper and lower blades is adjusted by the handle, and the dial indicates the value. The adjustment is easy, fast, accurate and reliable.

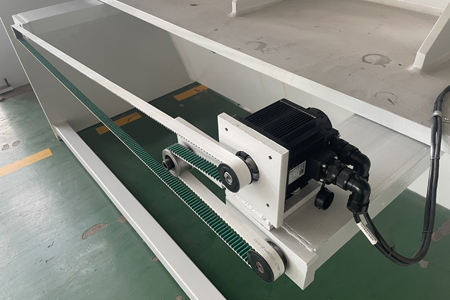

9. The electromechanical back gauge can be manually fine-tuned, and the size of the gauge and the number of shearing times have digital display devices, which are easy to use.

10. The working surface is equipped with a rolling structure to reduce sheet scratches and reduce frictional resistance.

| Specifications | Supplier |

| Seals | Japan VALQUA |

| Hydraulic valve | China Mainland |

| Electrical components | SIEMENS/SCHNEIDER |

| Main motor | China Mainland |

| Blades | China Mainland |

| Oil pump | China Mainland |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life