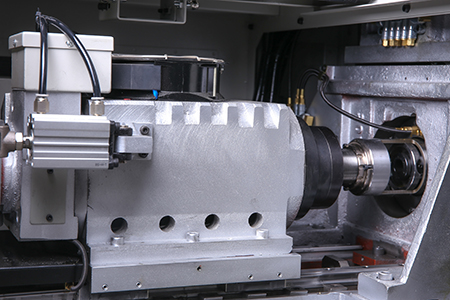

Swiss Type CNC Automatic Lathe F203E

Max dia. : φ21mm

Feeding length:140mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

Main Parts for the machine

| Name | Specifications | Quantity/Set | Details |

| CNC longitudinal cutting automatic lathe | F203E | 1/Set | —— |

| Oil film automatic feeder | 20 Type | 1/Set | —— |

| Number of turning tools | 12×12■/ 5PCS | 1/Set | Standard configuration |

| Spindle side power unit | ER16*2+ER11*2 | 1/Set | Standard configuration |

| Spindle face fixed tool | ER11*4 | 1/Set | Standard configuration |

| Fixed tool on counter shaft end face | ER11*4 | 1/Set | Standard configuration |

| Synchronous Rotation Guide Bushing | 1/Set | Standard configuration | |

| Product Automatic Receiver | 1/Set | Standard configuration | |

| Oil Mist Separator | 1/Set | Optional | |

| Chuck | TSUGAMI | 1/Set | Standard configuration |

| Bushing | TSUGAMI | 1/Set | Standard configuration |

| Remark | The distribution of driven tool holders can be selected according to product requirements | ||

Machine standard configuration

| No | Name | No | Name |

| 1 | Spindle clamping device | 11 | CNC device |

| 2 | Synchronous Rotary Guide Bushing | 12 | 4inch color LCD display |

| 3 | Parts Adapter | 13 | C axis control (main axis/back axis) |

| 4 | synchronization device | 14 | Rigid tapping |

| 5 | automatic lubrication system | 15 | RS-232 interface and DNC function |

| 6 | Cutting oil system | 16 | Electrical box heat discharge |

| 7 | Air cooling temperature control system | 17 | Gang knife seat |

| 8 | Product receiving device | 18 | Side Milling Power Head Unit |

| 9 | working lamp | 19 | End Drilling Seat |

| 10 | Warning Light | 20 | leakage protection device |

Resources & Downloads:

Swiss Type CNC Automatic Lathe F203E Product Introduction :

1.F203E is fully launched, and the upgraded spindle unit speeds up again: it only takes 1 second from 0 to 5000prm! Brand new appearance, more explicit operation!

The motor power is 2.273.7Kw, and the speed is stable and constant. Maximum working speed: spindle 8000r/min; side milling 6000r/min

2.The side milling adopts 750w Yaskawa servo electric drive, 5 sets of NSKF4 grade bearing assembly on a single shaft, and the side milling is very rigid during milling. 3. The feed of X, Y, and Z axes is driven by 750w Yaskawa servo, which makes the feed easier.

3.The processing accuracy can be stabilized above IT6 level.

4.Adopt the clamping method of Baiben machine tool to improve the accuracy of the second feeding, and adopt the double locking method of mechanical lock + servo lock when milling chips, which has higher precision and fully protected sheet metal to ensure the safety of the screw and guide rail. Long life, equipped with data output and input ports are more convenient for customer equipment management.

| Main axis (MAIN) configuration | Inner diameter 22 | ||

| Max dia.φ21mm | φ21mm | ||

| Feeding length at one time | 140mm | ||

| Max speed:8000rpm | 8000rpm | ||

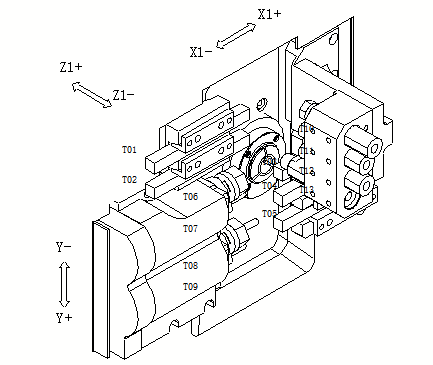

| Tool layout |  |

||

| Turning tool | Number of tools | 5 sticks | |

| Tool Specifications | 12mm | ||

| End processing | Number of tools | front fixing tool | 4sticks |

| drilling capacity | fixed tool | φ7mm | |

| Maximum cutting and tapping capacity | fixed tool | M6 | |

| Lateral Rotation Tool | Number of tools | 4sticks | |

| Tool Specifications | ER16*2+ER11*2 | ||

| drilling capacity | φ8mm | ||

| tapping capacity | M6 | ||

| milling capacity | φ10mm | ||

| Maximum saw blade milling cutter diameter | 30 mm | ||

| Maximum speed | 5000min-1 | ||

| Power | 0.75Kw | ||

| Rapid speed | Z1 | 24m/min | |

| X1 | 30m/min | ||

| Y1 | 30m/min | ||

| Spindle maximum working revolutions | 8000min-1 | ||

| Spindle degrees | C-axis control (0.001º) | ||

| Spindle power | 3.7/2.2kw | ||

| Spindle through hole diameter | φ22mm | ||

| Coolant capacity | 100L | ||

| cooling motor power | 0.85kw | ||

| Dimensions (L*W*H) | 1750×910×1700 | ||

| Machine weight | 1800kg | ||

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life