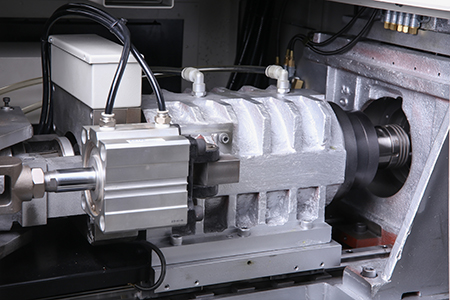

Swiss Type CNC Automatic Lathe G206E

Max dia. :21mm

Feeding length:140mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

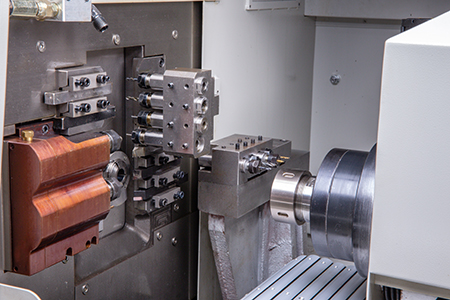

Main Parts for the machine

| Name | Specifications | Quantity/Set | Details |

| CNC longitudinal cutting automatic lathe | G206E | 1/Set | —— |

| Oil film automatic feeder | TY326 | 1/Set | —— |

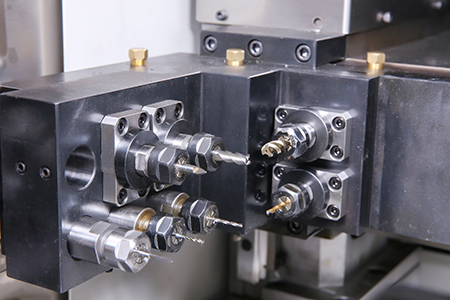

| Number of turning tools | 12×12■/ 5PCS | 1/Set | Standard configuration |

| Spindle side power unit | ER16*2+ER11*2 | 1/Set | Standard configuration |

| Spindle face fixed tool | ER11*4 | 1/Set | Standard configuration |

| Sub-spindle fixed tool on the end face | ER11*4 | 1/Set | Standard configuration |

| Sub-spindle side power | ER11*2 | 1/Set | |

| Sub-spindle end face power | ER16*2 | 1/Set | |

| Synchronous Rotation Guide Bushing | 1/Set | Standard configuration | |

| Product Automatic Receiver | 1/Set | Standard configuration | |

| High pressure pump | 1/Set | Optional | |

| Oil Mist Separator | 1/Set | Optional | |

| Chuck | TSUGAMI | 1/Set | Standard configuration |

| Bushing | TSUGAMI | 1/Set | Standard configuration |

| Remark | The distribution of driven tool holders can be selected according to product requirements | ||

Machine standard configuration

| Name and brand/origin | Name and brand/origin |

| Spindle clamping device (China) | Operating system CNC SYNTEC (Taiwan, China) |

| The second spindle clamping device (China) | 10.4inch Color LCD display (China) |

| Synchronous rotary guide bush (China) | C-axis control (main axis/back axis) (China) |

| Parts transfer device (China) | Rigid tapping (China) |

| Synchronization device (China) | RS-232 interface and DNC function |

| Automatic lubrication system (China) | Electrical box heat discharge |

| Cutting oil system (China) | Knife block (China) |

| Air-cooled temperature control system (China) | Side milling power head unit (China) |

| Product conveyor device (China) | End face drilling seat (China) |

| Oil mist separator (China) | Back end power unit (China) |

| Air pressure original (Taiwan, China) | Sub-spindle blowing device (China) |

| Work lights (China) | Leakage protection device (China) |

| Warning light (China) | Control system (CNC) optional: Japan Mitsubishi, Taiwan LNC. The delivery time of FANUC is three months. |

Resources & Downloads:

Swiss Type CNC Automatic Lathe G206E Product Introduction :

Shanghai ANTISHI G206E Swiss-type CNC longitudinal cutting machine tool can meet all processing procedures such as cutting, milling, drilling, and grinding for the above products. If there are products with more changeable process and process requirements, our company can provide other types of machine tools for customers to choose according to customers’ processing requirements.

| Specifications | G206E | ||

| Main axis (MAIN) configuration | Inner diameter 22 | ||

| Max Processing material diameter | 21mm | ||

| Feeding length at one time | 140mm | ||

| Spindle setting working speed | 8000 Rpm | ||

| Turning tool | Number of tools | 5pcs | |

| Tool Specifications | □12x12mm | ||

| End processing | Number of tools | Front Fixing Tool | 4pcs |

| drilling capacity | Fixed Tool | Φ7mm | |

| Maximum cutting and tapping capacity | Fixed Tool | M6 | |

| Lateral Rotation Tool | Number of tools | 4pcs | |

| Tool Specifications | ER16*2+ER11*2 | ||

| Drilling Capacity | φ8mm | ||

| Tapping Capacity | M6 | ||

| Milling Capacity | φ10mm | ||

| Max. saw blade milling cutter diameter | 30 mm | ||

| Max. speed | 5000min-1 | ||

| power | 0.75Kw | ||

| Rapid speed | Z1 | 24m/min | |

| X1 | 30m/min | ||

| Y1 | 30m/min | ||

| Spindle maximum working revolutions | 8000min-1 | ||

| Spindle positioning accuracy | C-axis control (0.001º) | ||

| Spindle power | 3.7/2.2kw | ||

| Spindle through hole diameter | φ22mm | ||

| Coolant capacity | 100L | ||

| Cooling motor power | 0.85kw | ||

| Dimensions (L*W*H) | 2100*1100*1780mm | ||

| Machine weight | 2800kg | ||

| Sub-spindle (SUB) configuration | |||

| Max. machining diameter | φ20mm | ||

| Max. discharge part length | 80mm (the rear discharge length is not limited) | ||

| Max. clamping protrusion length | 50mm | ||

| Fixed processing tool holder and driven tool holder | ER11/ER16 | 5 pieces (2 power knives and 3 fixed knives can be selected) or 4 power knives | |

| Rapid speed | Z2 | 24m/min | |

| X2 | 30m/min | ||

| Max. number of revolutions of the second spindle | 8,000min-1 | ||

| Positioning accuracy of the second spindle | C-axis control (0.001º) | ||

| Second spindle power | 2.2/1.1kw | ||

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life