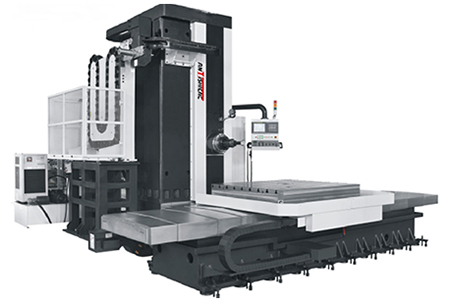

TK160T3 CNC Horizontal Boring and Milling Machining Center

X-axis travel : 3000mm

Y-axis travel : 2500mm

Z-axis travel : 1500mm

W-axis travel : 900mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Description/Machine Model | Unit | TK160T3 | |

| Motor spindle | |||

| Spindle motor | kW | 30/37 | |

| Spindle speed | rpm | 35-2000 | |

| Spindle speed change | Gear | ||

| Spindle inner cone hole | ISO50(BT50) | ||

| W-axis diameter | mm | 160 | |

| Maximum spindle torque | Nm | 3675 | |

| Scope of work | |||

| X-axis stroke | mm | 3000 | |

| Y-axis stroke | mm | 2500 | |

| Z-axis stroke | mm | 1500 | |

| W-axis stroke | mm | 900 | |

| Distance from spindle center to workbench | mm | 50-2550 | |

| Rotating ktable | |||

| table size | mm | 2500×2500 | |

| Maximum load capacity of table | kg | 20000 | |

| Minimum rotation angle of table | ° | 0.001 | |

| Feed | |||

| Rapid feed rate | X-axis | mm/min | 10,000 |

| Y-axis | mm/min | 10,000 | |

| Z-axis | mm/min | 10,000 | |

| W-axis | mm/min | 4,000 | |

| Workbench speed | rpm | 1 | |

| Cutting feed rate | X-axis | mm/min | 6,000 |

| Y-axis | mm/min | 6,000 | |

| Z-axis | mm/min | 6,000 | |

| W-axis | mm/min | 2,000 | |

| Minimum input unit | mm | 0.001 | |

| Pulling nail specifications | BT50-45° | ||

| Accuracy | |||

| X axis positioning accuracy/entire length | mm | 0.025(Full closed-loop) | |

| Y axis positioning accuracy/entire length | mm | 0.025(Full closed-loop) | |

| Z axis positioning accuracy/entire length | mm | 0.020(Full closed-loop) | |

| W axis positioning accuracy/entire length | mm | 0.020(Semi closed loop) | |

| B axis positioning accuracy | ″ | 15(Full closed-loop) | |

| X axis repeated positioning accuracy | mm | 0.020 | |

| Y/Z/W axis repeated positioning accuracy | mm | 0.015 | |

| B axis repeated positioning accuracy | ″ | 8 | |

| Others | |||

| Cover an area | Length × Width | mm | 9500×9200 |

| Height | mm | 6000 | |

| Machine weight (approximately) | kg | 40,500 | |

| CNC system | FANUC 0I-MF(1) | ||

| Tool magazine | |||

| Tool capacity | 24 | ||

| Maximum tool weight | kg | 25 | |

| Maximum tool length | mm | 400 | |

| Maximum tool diameter (full tool) | mm | 125 | |

| Maximum tool diameter (adjacent to empty tool) | mm | 250 | |

Resources & Downloads:

TK160T3 CNC Horizontal Boring and Milling Machining Center Product Introduction :

1.Technical description

XYZ-axis hard rail, spindle motor 30/37kW; equipped with 2500 × 2500mm one thousandth degree CNC turntable, bearing 20t; equipped with X/y/z/b four-axis grating; equipped with FANUC 0I-MF (1) CNC system. Taiwan first-class quality standards, 24-hour non-stop high-efficiency processing.

This horizontal milling and boring machine is a CNC machine tool developed by absorbing advanced manufacturing technology from abroad. After multiple improvements and upgrades, it has now formed a relatively complete modular series of products. This product has mature technological means, stable product quality, and its technical indicators and software and hardware configurations are at the international advanced level. It is a high-end product in the CNC category.

The machine tool has various processing functions such as boring, milling, drilling (drilling, expanding, hinge), threading (rigid tapping), spot milling, turning, etc. The excellent CNC system also enables the machine tool to have linear interpolation, circular interpolation, and four-axis linkage functions. The CNC rotary worktable can achieve multi process machining of hole groups, hole systems, and planes on four surfaces with one clamping of the workpiece. Horizontal milling and boring machines are widely used in various general machinery processing industries such as aviation, aerospace, shipbuilding, transportation, railways, military industry, energy, wind power, nuclear power, heavy-duty, metallurgy, mining, engineering machinery, petrochemical machinery, internal combustion engines, water pumps, etc. They are the key preferred equipment for processing parts such as box bodies, shells, and machine bases.

2.Main structure

Following the original design philosophy of Nomura Manufacturing in Japan, the static and dynamic rigidity of the body is analyzed from the Kraft flow to the Finite Element Method, ensuring that the machine tool maintains maximum load and minimum deformation, while suppressing vibration to ensure machining accuracy. The entire casting is processed and manufactured in Taiwan, with strict quality control. The high-strength mihanna cast iron and fully supported T-shaped dynamic column design not only improve machining accuracy, but also ensure the durability and reliability of the machine.

The machine tool is a single column, side hanging box; The workbench and its slide seat move on the horizontal bed body (X-axis coordinate), the spindle box moves vertically along the column guide rail (Y-axis coordinate), and the column is fixed on the slide seat and moves along the vertical bed guide rail (Z-axis coordinate); Layout the bed in T font. The CNC worktable rotates 360 degrees (B coordinate), and the spindle (boring axis) (W coordinate) moves within the milling axis.

3.X-axis three-line rail, YZ-axis hard rail

X-axis three-line rail, YZ-axis hard rail, and all castings are precision machined after secondary annealing. The surface of the guide rail is subjected to medium frequency wave heat treatment, with a hardening depth of 3mm and a hardness of HRC 50 ± 2 ° C. After high-precision surface grinding, each rail can be assembled online only after being measured by a precision optical laser instrument (Auto crossmeter). The relative sliding surface adopts Japanese Turcite wear-resistant plates combined with precision grade chisels, creating excellent, reliable, and durable precision for the track, and providing the rigidity and stability required for heavy cutting.

4.Head (patented structure)

Main spindle power torque diagram:

All components of the main spindle box are self-produced, and the bearings are made of Japanese NSK precision grade, paired with European gearboxes. Each main spindle box undergoes strict independent inspection from the machining of the spindle shaft to the expansion and contraction of the outer cylinder (0.006-0.012mm), and each process undergoes precision inspection. An accuracy inspection table is prepared and shipped with the machine for quality traceability. After each spindle box is assembled, it must undergo a complete 96 hour temperature rise running in test to ensure that the bearing preloading and assembly accuracy meet the specifications. Each spindle unit, under strict control, achieves high precision with an overhang of 300mm and a deviation of ≤ 0.010mm, and a total overhang of 700 ≤ 0.025 sag.

5.B-axis workbench unit

When the turntable is working, the control system sends a start signal. Firstly, the hydraulic cylinder is clamped to release the oil inlet, and the piston rises. The servo motor drives the worktable to rotate through the worm gear and worm gear pair. When it turns to the desired position, the servo motor stops rotating and simultaneously sends a brake command. The clamping port of the hydraulic cylinder is filled with oil, and the pressure electrical device sends a brake signal. The worktable indexing work is completed (with an appropriate delay for safety reasons), The main engine starts working (note: when the main engine is working, the brake port should be continuously lubricated to ensure reliable braking)

6.Column

The high-quality mihanna cast iron body adopts a high-strength arch bridge auxiliary structure inside, which improves the rigidity of the column by 27%. It undergoes two electric furnace aging and two vibration aging to ensure long-term seismic resistance without deformation.

7.Hydraulic system

The hydraulic system functions include automatic unclamping of the spindle, balance cylinder of the ram, etc. The system adopts integrated installation to ensure the reliability of the entire machine’s movement and facilitate maintenance.

8.Lubricating system

The guide rail and screw of the entire machine are equipped with a quantitative lubrication system, which can adjust the oil supply cycle and amount at each lubrication point, and achieve fully automatic centralized lubrication through electrical system control.

9.Cooling system

The constant temperature cooling system can effectively cool the spindle system,ensuring the accuracy and stability of the main movement of the machine tool; The tool cooling system, namely the cutting fluid device and cutting air blowing device, can timely remove the heat generated during the machining process.

10.Chip removal device

A set of spiral chip conveyor is distributed on both sides of the workbench, and the equipment is equipped with a lifting chain plate chip conveyor and a chip conveyor car at the end.

11.Other configuration instructions

The work area is equipped with lighting to adapt to night work.

The machine tool is equipped with three color lights, which provide three types of information: program operation, completion of work cycle, and fault alarm.

12.Casting

Casting: optimal cast iron: professional large factory, high-quality pig iron, electric furnace annealing.

Stress relief: electric furnace first annealing – natural aging (4-6 months) – vibration aging (4 hours) – rough machining – electric furnace second annealing – semi fine machining – natural cooling for 3 days – vibration aging (4 hours – fine machining)

Standard configuration

| NO. | Standard accessory specifications | Number |

| 1. | Centralized automatic lubrication system | 1 |

| 2. | Splash protection cover and manual door | 1 |

| 3. | Cutting fluid cooling pump and water tank | 1 |

| 4. | Hand pulse box | 1 |

| 5. | Pneumatic device | 1 |

| 6. | Hydraulic device | 1 |

| 7. | Automatic power outage device | 1 |

| 8. | Work lights | 1 |

| 9. | Warning lights | 1 |

| 10. | Foundation bolts and horizontal adjustment screws | 1 |

Main purchased parts

| NO. | Project | Brand | Place of production |

| 1. | CNC system | FANUC | Japan |

| 2. | Spindle motor | FANUC | Japan |

| 3. | X/Y/Z axis servo motor | FANUC | Japan |

| 4. | Ball screw | THK | Japan |

| 5. | Bearings for ball screws | NSK | Japan |

| 6. | Grating ruler | FAGOR | Spain |

| 7. | Spindle oil cooling device | TNP | Joint venture |

| 8. | Electric cabinet air conditioning | Laber | China |

| 9. | Automatic lubrication device | HERG | China |

| 10. | Telescopic cover | Xinweixv | China |

| 11. | Spindle | Technology of Taiwan China | |

| 12. | Coupling | Mikipulley | Japan |

| 13. | Hydraulic unit | Aishun | China |

| 14. | Transformer | Xingwen | China |

| 15. | Pneumatic | Airtag | Taiwan, China |

| 16. | Balance valve | Dikin/Yuken | Japan |

| 17. | Other electronic components | SCHNEIDER/OMRON | France/Japan |

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life