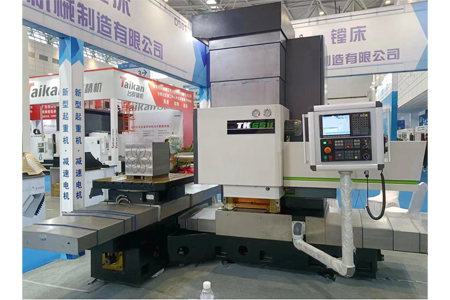

TK6511/TK6513 planer table milling and boring machine

3 models

X-axis travel : 2000mm

Y-axis travel : 1700mm

Z-axis travel : 900mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| TK6511/TK6513 CNC planer table milling and boring machine

Technical parameters |

||||

| ITEM | Parameter item | TK6511 | TK6511B | TK6513 |

| Spindle | Spindle diameter | φ110 mm | φ110 mm | φ130 mm |

| Spindle taper | ISO 50 | ISO 50 | ISO 50 | |

| Spindle speed | 20-1000 r/min | 20-1000 r/min | 20-950 r/min | |

| Max. Spindle torque | 447 N.m | 447 N.m | 680 N.m | |

| Max. Spindle thrust | 18000 N | 18000 N | 20000 N | |

| Main drive motor power | 15 kw | 15 kw | 16 kw | |

| Spindle speed reduction type | Direct-drive | Direct-drive | Direct-drive | |

| Travel and

feed speed |

Worktable transverse stroke:X-axis | 1400 mm | 1800 mm | 2000 mm |

| Headstock vertical stroke:Y-axis | 900 mm | 1200 mm | 1700 mm | |

| Longitudinal travel Z axis | 700 mm | 700 mm | 900 mm | |

| Spindle travel W | 600 mm | 600 mm | 800 mm | |

| Movement speed X/Y/Z | 1-5500 mm/min | 1-5500 mm/min | 1-8000 mm/min | |

| Worktable | Table size | 900*1200 mm | 900*1300 mm | 1400*1600 mm |

| Max.load on the table | 5000 kg | 5000 kg | 10000 kg | |

| Rotation of table | 360° rotation /4*90°positioning | |||

| Accuracy | Positioning accuracy (X/Y/Z) | 0.04 / 0.032 / 0.032 mm | 0.04 / 0.04 / 0.032 mm | |

| Repeatable accuracy (X/Y/Z) | 0.02 / 0.018 / 0.018 mm | 0.02 / 0.02 / 0.018 mm | ||

| Installation

data |

CC system | HUAZHONG Numerical Control System | ||

| Dimensions of machine | 3500*4200*3100 mm | 4000*4200*3600 mm | 4800*5000*4800 mm | |

| Machine weight | 10000 kg | 12000 kg | 19000 kg | |

Resources & Downloads:

TK6511/TK6513 planer table milling and boring machine Product Introduction :

Product Details

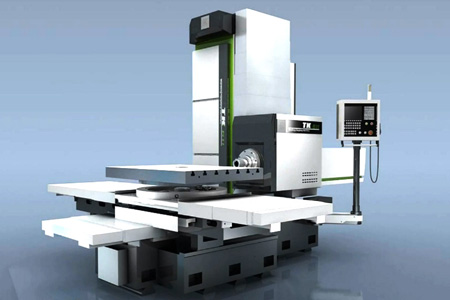

TK65 series planer type milling and boring machine is T-shaped movable column type, side-mounted head-stock structure: the bed is an overall T-shaped type. The worktable moves laterally along the front bed as the X axis, the column is fixed on the sliding seat, the sliding seat moves longitudinally along the rear bed guide rail as the Z axis, the spindle box moves along the vertical direction of the column guide as the Y axis, and the boring shaft moves axially as W axis.

The overall structure design of the machine tool adopts FEM finite element analysis, and reasonable reinforcement is carried out to ensure its high rigidity and stability.

All basic large pieces are made of high-quality gray cast iron, cast by resin sand casting process, and treated with two aging treatments.

Features

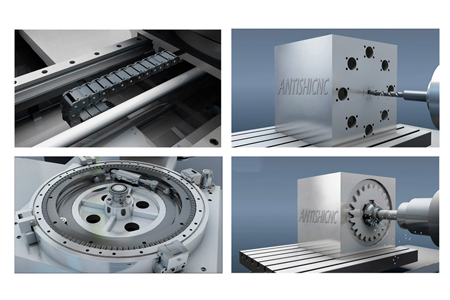

1. The main drive system adopts numerical control direct drive near-zero transmission technology, with few transmission parts and high transmission precision. The high-torque AC servo motor directly drives the main shaft, with low energy consumption, low noise, low failure rate, and easy maintenance. The spindle speed range is large and the torque output is large.

2. The ed technology of the short cylindrical rolling rotary table significantly improves the support capacity and reliability of the table.

3. The servo feeding devices of each coordinate axis are all driven by AC servo motors, and are supported by preload-ed ball screws and special angular contact bearings.

4. The head stock adopts nitrogen balance system, which is more stable, reliable and safe.

5. The towline has built-in ed technology, which can effectively protect the pipeline operation system, reduce the failure rate and improve the overall aesthetics.

Standard Equipment

1 CNC system(HUAZHONG)

2 Spindles

3 Spindle bearing

4 Lead screw rails

5 Main electrical components

6 large bed base

7 CNC electrical cabinet industrial air conditioner

8 Timing quantitative lubrication pump

Optional Equipment

SIEMENS/FANUC CNC SYSTEM

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life