TPK611C Heavy Duty Large CNC Milling Boring Machine

Table size : 1320*1010mm

Max. Drilling Dia. : φ50 mm

Max. Boring Dia. : φ240 mm

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Technical ITEMS|Model | TPK611C |

| Max. load of worktable | 2500kg |

| Table size | 1320*1010mm |

| Max. allowable torque on spindle | 1100N.m |

| Max. allowable torque on facing head tool holder | 1100N.m |

| Max. allowable axial feed force on spindle | 13000N |

| Spindle speed step | No step |

| speed step of facing head | No step |

| Spindle speed range | 12-1100r/min |

| Facing head speed range | 4-130r/min |

| Rapid feed speed of spindle | 3600mm/min |

| rapid feed speed of facing head radial tool holder | 1180mm/min |

| Spindle diameter | 110mm |

| Max. distance from spindle nose to table surface | 905mm |

| Min. distance from spindle nose to table surface | 5mm |

| Vertical travel of headstock | 900mm |

| Spindle axial travel | 550 mm |

| radial travel of facing head tool holder | 160 mm |

| Longitudinal travel of table | 1350 mm |

| Cross travel of table | 1250 mm |

| Max. boring diameter of spindle | φ240 mm |

| Max. diameter of facing head tool holder | φ630 mm |

| Max. drilling diameter | φ50 mm |

| Spindle taper | BT50 |

| Main motor power | 11/15kW |

| Rapid feed speed of X,Y,Z | 5000mm/min |

| positioning accuracy of coordinate | X,Z:0.04 mm

Y:0.032mm |

| positioning accuracy | 0.02/500mm |

| Repeat positioning accuracy | 0.014/500 |

| Overall dimension(L*W*H) | 5375×2995×3035 mm |

| Net. weight | 12300kg |

Resources & Downloads:

TPK611C Heavy Duty Large CNC Milling Boring Machine Product Introduction :

Product Details:

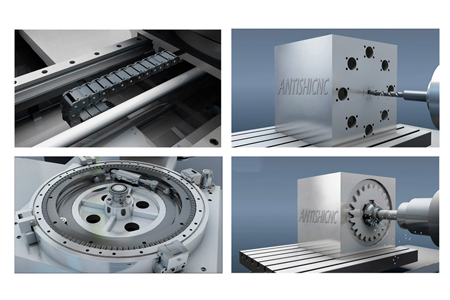

This series of CNC horizontal boring milling machine adopts the layout of single-column and side-mounted box, and the worktable adopts the structure of four-point positioning and manual rotation (360°×1° or 5° indexing of the CNC turntable with Hirth ring structure can be selected).

X, Y, Z axes are controlled by numerical control system, which can realize three-axis linkage. The feed of the boring shaft can be controlled by servo motor to realize the automatic expansion and contraction of the boring shaft.

X, Y, Z axis adopts rectangular sliding guide rail, PTFE plastic paste technology, good shock absorption and high precision.

The head-stock adopts the weight balance method. The main shaft and flat turntable are controlled by AC servo motor.

Spindle

Horizontal boring machine spindle box adopts the weight balance method. The main shaft and the swinging plate are controlled by AC servo motors.

Horizontal boring machine XYZ axis is controlled by the CNC system, which can realize three-axis linkage. The expansion and contraction of the boring shaft and the rotation of the flat rotating disk are controlled by a servo motor, which can realize automatic processing.

The XYZ axis adopts a rectangular sliding guide rail and pasting process, which has good shock absorption and high precision.

Worktable

Worktable

Horizontal boring machine platform

High-strength cast iron HT200-300, the working surface hardness is HB170-240, after two manual treatments (artificial annealing 600 degrees -700 degrees or natural aging for 2-3 years) so the product has stable precision and good wear resistance. The guide rail is refrigerated and hardened with high wear resistance.

CNC system

Standard type: Fanuc CNC system

other system such as Siemens, Mitsubishi, GSK, and FAGOR can choose.

FANUC Series 0i-MODEL F Plus has been released with renewed design, enhanced basic functions and the pursuit of ease of use.

It is equipped with the latest control technology for fine surface machining and reducing cycle time, and with customizable functions that can flexibly create screens suitable for machine tools.

Standard Equipment

FANUC 0i MF CNC SYSTEM

Manual rotary table

Pad iron

Anchor bolts

Electronic handwheel, etc

Optional Equipment

Hirth structure CNC turntable

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life