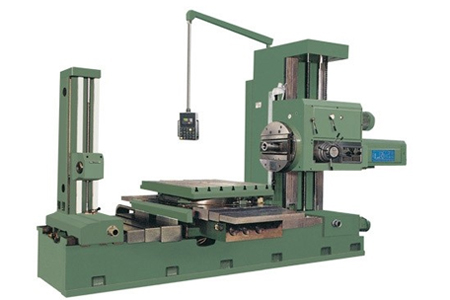

TPX Series Horizontal Milling Boring Machine

7 models

X/Y/Z/W/U axis travel

For larger parts

No installation required

Simple operation

Support video teaching

1 Year for machinery warranty

On Stock

Email : contact@antsmachine.com

(your request will be responsed within 1 hour.)

Technical Parameter :

| Specifications | Unit | TPX6111B | TPX6111B/2 | TPX6111B/3 | TPX6113 | TPX6113/2 | TPX6211 | TPX6213 | ||

| Spindle | ||||||||||

| Spindle Diameter | mm | 110 | 110 | 110 | 130 | 130 | 110 | 130 | ||

| SpindleTaper bore | 一 | Morse 6 | Morse 6 | Morse 6 | Metric 80 | Metric 80 | Morse 6 | Metric 80 | ||

| Max. spindle torque | Nm | 1225 | 1225 | 1225 | 3136 | 3136 | 1225 | 3136 | ||

| Max.axial resistance of spindle | N | 12250 | 12250 | 12250 | 31360 | 31360 | 12250 | 31360 | ||

| Spindle speed level | 一 | 22 | 22 | 22 | 24 | 24 | 22 | 24 | ||

| Spindle speed range | r/min | 8-1000 | 8-1000 | 8-1000 | 4-800 | 4-800 | 8-1000 | 4-800 | ||

| Main motor power | KW | 7.5 | 7.5 | 7.5 | 15 | 15 | 7.5 | 15 | ||

| Facing head | ||||||||||

| Maximum torque of Facing head | Nm | 1960 | 1960 | 1960 | 4900 | 4900 | 1960 | 4900 | ||

| Facing head diameter | mm | 2600 | 2600 | 2600 | 2750 | 2750 | 2600 | 2750 | ||

| Range of facing head speed | r/min | 4-200 | 4-200 | 4-200 | 2.5-125 | 2.5-125 | 4-200 | 2.5-125 | ||

| Number of facing head speed | 一 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | ||

| Worktable | ||||||||||

| Size(length×width) | mm | 1100×960 | 1100×960 | 1250×1100 | 1600×1400 | 1800×1600 | Special accessorie | Special accessorie | ||

| Max. load capacity | kg | 2500 | 2500 | 2500 | 8000 | 10000 | 一 | 一 | ||

| T-slot size | mm | 22 | 22 | 22 | 28 | 28 | 一 | 一 | ||

| Number of T-slots | 一 | 7 | 7 | 7 | 9 | 11 | 一 | 一 | ||

| Travel | ||||||||||

| X-axis travel | mm | 900 | 1250 | 1600 | 1600 | 2000 | 2000(Custom lengths are available) | 1750(Custom lengths are available) | ||

| Y-axis travel | mm | 900 | 900 | 1200 | 1400 | 1800 | 1600 | 1600/2000/2500 | ||

| Z-axis travel | mm | 1400 | 1400 | 1400 | 2000 | 2000 | 一 | |||

| W-axis travel (spindle travel) | mm | 600 | 600 | 600 | 900 | 900 | 600 | 900 | ||

| U-axis travel (Slider travel of Facing head ) | mm | 180 | 180 | 180 | 250 | 250 | 180 | 250 | ||

| B-axis swing angle | ° | 360 | 360 | 360 | 360 | 360 | 一 | 一 | ||

| Min. distance from spindle centre to worktable surface | mm | 0 | 0 | 0 | 0 | 0 | 一 | 一 | ||

| Feeding speed | ||||||||||

| Fast speed | mm/min | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | ||

| Feed range of each axis per spindle revolution | mm/rev | 0.046/0.01-188 (X/Y/Z/W) |

0046/001-1.88 (X/Y/Z/W) |

0.046/0.01-1.88 (X/Y/Z/W) |

0.05-8/0.01-2 (X/Y/Z/W) |

0.05-8/0.01-2 (X/Y/Z/W) |

0.04-6/0.01-1.88 (X/Y/Z/W) |

0.05-8/0.01-2 (X/Y/Z/W) |

||

| Accuracy | ||||||||||

| Linear measurement system reading accuracy (X/Y/Z) (Optional:Z-axis measurement ) | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | ||

| B-axis angle measurement system reading accuracy(Optional B-axis measurement users) | 一 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 一 | 一 | ||

| General parameter | ||||||||||

| Overall Dimension(L×W×H) | mm | 4910×2454×2750 | 430×2870×2750 | 5028×3359×3079 | 606×3647×3442 | 7030×46×3800 | According to the specifications | According to the specifications | ||

| Weight | kg | 11500 | 13000 | 14000 | 24000 | 28000 | ||||

| Standard equpment | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | Spindle taper bore 7:24 50# | |||

| Facing head | Facing head | Facing head | Facing head | Facing head | 一 | 一 | ||||

| XY axis DRO Digital display | XY axis DRO Digital display | XY axis DRO Digital display | XY axis DRO Digital display | XY axis DRO Digital display | XY axis DRO Digital display | XY axis DRO Digital display | ||||

| Optional equipment | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | Spindle taper bore can choose by customer needs | |||

| Rear column | Rear column | Rear column | Rear column | Rear column | Detachable Facing head | Detachable Facing head | ||||

| Z-axis DRO Digital display | Z-axis DRO Digital display | Z-axis DRO Digital display | Z-axis DRO Digital display | Z-axis DRO Digital display | Right Angle Milling Head | Right Angle Milling Head | ||||

| B-axis DRO Digital display | B-axis DRO Digital display | B-axis DRO Digital display | B-axis DRO Digital display | B-axis DRO Digital display | 一 | Universal Milling Head | ||||

Resources & Downloads:

TPX Series Horizontal Milling Boring Machine Product Introduction :

Products Features:

This series of machine is a universal one in that they complete a variety machining on castings, steel parts, and parts made of non-ferrous matals, for example, drilling, enlarging, boring, and reaming holes, milling planes, facing spots and cutting threads.The slide of face plate of this machine can feed in a radial direction thus enlarge the dimension of boring, turning and grooving.

Worktable: optical sighting device is employed to achieve high positioning accuracy.

Spindle: exhibits high accuracy on account of three-point stay, as well as high hardness and long service life thanks to surface nltrogen treatment.

Face plate: it is able to porcess larger holes, external cutting and grooves.

Excellent performance

1. The spindle is a three-layer structure, with good rigidity, stable cutting performance, and a wide speed range.

2. The spindle speed change and feed adopts hydraulic pr-selection, which is easy to operate, labor-saving, high-efficiency, and improves the degree of automation.

3. The distribution and clamping of the lifting of the spindle box, the vertical and horizontal movement of the worktable and the rotary movement are all centrally controlled by the button station, which has good interlocking, time-saving, labor-saving, convenient and reliable operation.

4. The worktable 4 × 90 degrees adopts an optical sight with high positioning accuracy.

5. All moving parts are clamped by hydraulic-diamond block force boosting mechanism, with large clamping force and reliable clamping.

6. The main parts of the bed, column and spindle have taken wear-resistant measures to improve the service life.

7. The guide rail of the bed and sliding seat adopts fully enclosed stainless steel protection plate to protect the guide rail, and the appearance is pleasant.

8. The X and Y coordinates are equipped with a domestic grating digital display measuring device with high resolution, is 0.005 mm.

9. Digital display horizontal milling and boring machine absorbs foreign advanced technology in structure and manufacturing technology. It is a digital display machine developed according to the modular design method.

10. Suitable for milling, drilling, boring, tapping, turning, milling end faces, etc. of multi-working surfaces for larger parts.

Machine structure features

The overall design layout of the machine tool is a T-shaped separation structure of the vertical and horizontal bed, the spindle box moves vertically, and the worktable is moved vertically and horizontally.

X,Y,Z axis coordinates , the hardness can reach 45°-50°after quenching and finishing, high precision, low friction, and good precision retention.

The movement mechanism adopts a fast motor to move quickly through multiple parts of the fast box.The built-in feed system of the head stock drives each part to make the feeding movement.The spindle box and worktable are equipped with hydraulic locking device, which has stable movement, high positioning accuracy and large bearing capacity.

The double nut mechanism is used to eliminate the transmission gap and ensure the displacement accuracy.

X,Z axis using drawer type steel plate cover,Y axis guide rails are equipped with an organ-style protective cover,dust proof, waterproof, protect the guide rail, lead screw, with pleasant appearance. The main spindle bearings, screw bearings and table bearings are all genuine P5 grade bearings of Wafangdian(ZWZ).

X,Y,Z axis adopts Shenzhen Bowang grating ruler,the B axis adopts a circular digital display.

Standard Equipment:

Metric 80 Machine Set

Without rear pillar

Flat disc plate

XY axis NEWALL digital display ruler

Rotary table

Cast iron rails

Optional Equipment:

Rear column

ISO 7:2450 spindle

Z-direction digital display

B-axis digital display (±20″)

Get The Required Product Quotation As Quickly As Possible

If possible, Given detailed request helps to gain better-matched customized solution. Thanks for your patience. your request will be responsed within 1 hours, kindly pay attention to your email please.

WHAT OUR CLIENTS SAY

Deliver good machines, enjoy good life